A self-cleaning solar panel

A solar power generation panel and self-cleaning technology, applied in solar thermal power generation, solar thermal energy, solar collectors, etc., can solve problems such as scalding workers, influence of solar power generation efficiency, and large number of solar power generation panels, to achieve Improve the effectiveness of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

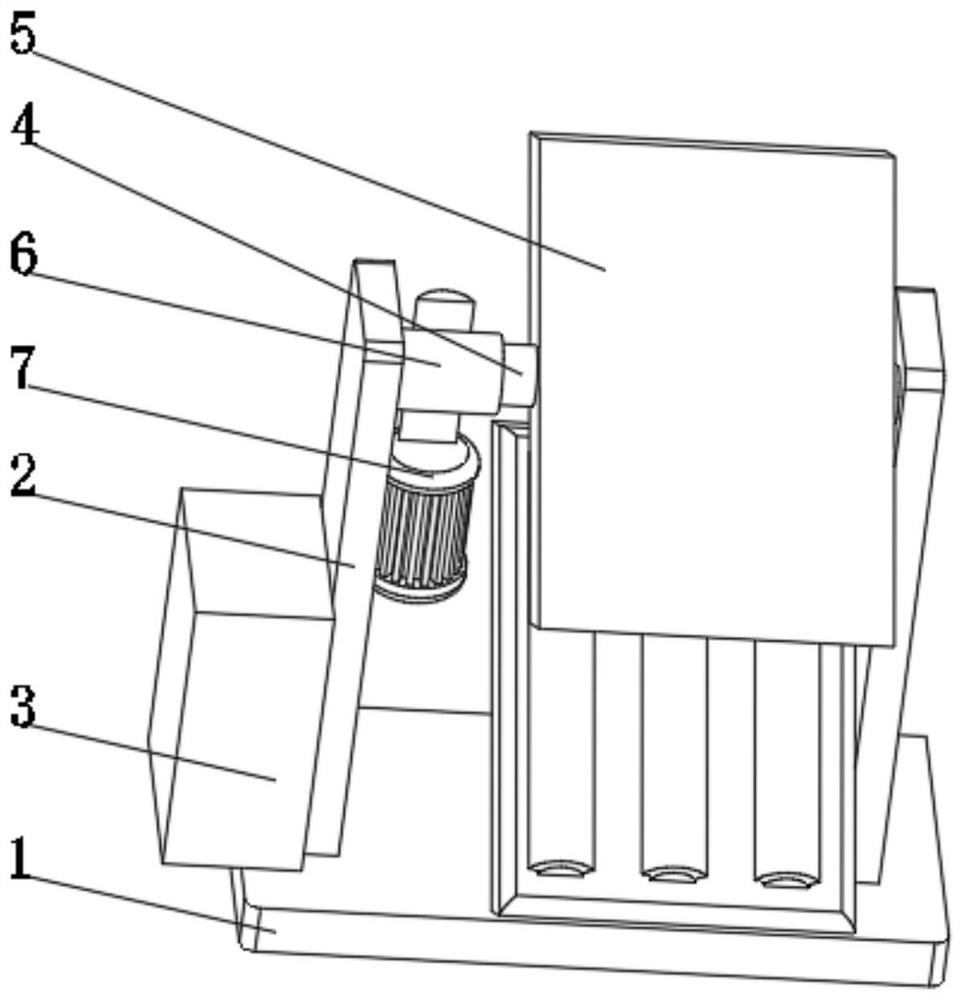

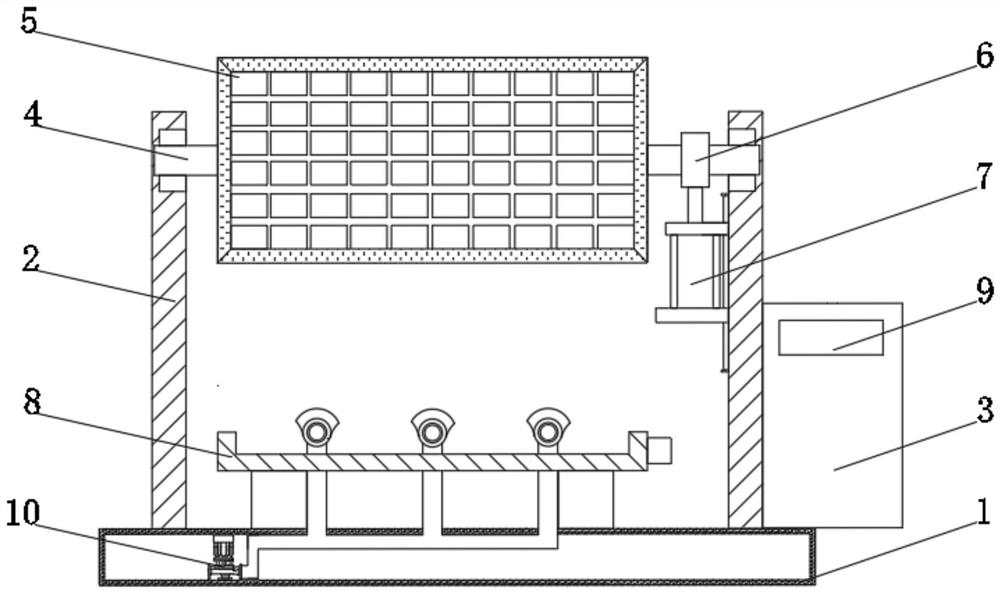

[0033] See Figure 1-2 The present invention provides a technical solution: a self-cleaning solar power generation plate comprising a water storage base 1, the top fixing bracket 2 of the reservoir base 1, the fixed bracket 2 fixedly connected to the control electrical cabinet 3 The inner side of the fixing bracket 2 is rotated by the bearing, and the side surfaces of the rotation shaft 4 are fixedly connected to the solar power generation plate 5, and the connecting seat 6 is rotatably connected, and the rotating connection seat 6 is fixedly connected. The lifting device 7, the side of the lifting device 7 is slidably connected to the fixing bracket 2 by a slider and a slide, and a cleaning mechanism 8 is provided below the solar power generation plate 5, the cleaning mechanism 8 away from the solar power generation board 5. On the side of the telescopic device and the reservoir base 1, the control electrical cabinet 3 is provided with a thermal sensing resistor 9, and a water pum...

Embodiment 2

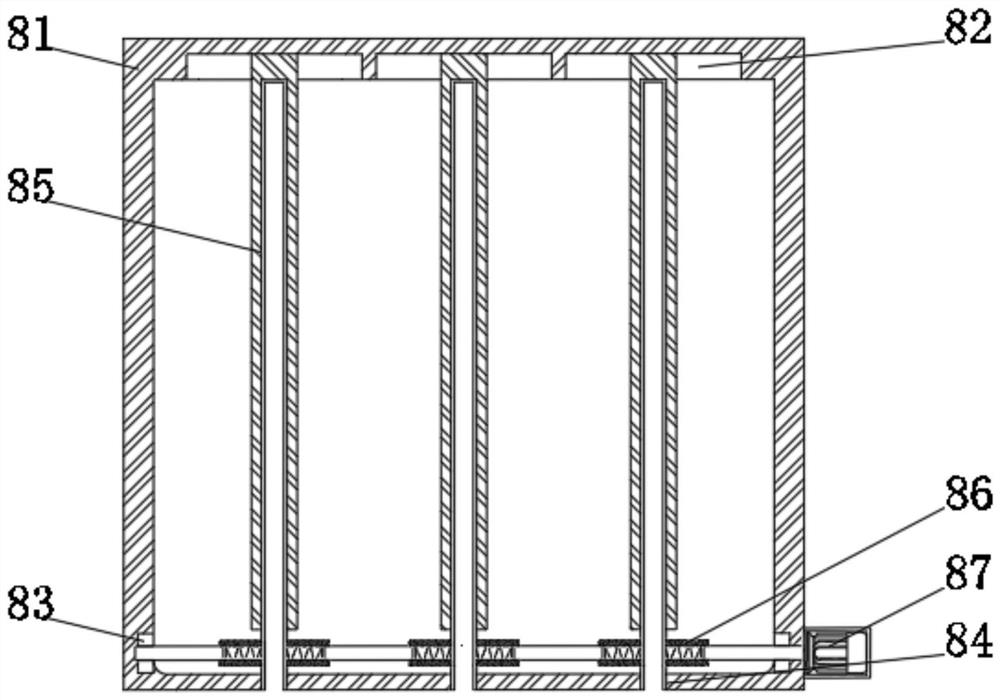

[0036] See Figure 2-5 The present invention provides a technical solution on the basis of the first example: a self-cleaning solar power generation plate, and the cleaning device 85 includes a connecting post 850, and the connection post 850 is provided with an in-water housing 851, the water water The inner wall side of the housing 851 is fixedly coupled with a reed 852, and the reed 852 is fixedly connected to one side of the inlet housing 851, and the water absorbing housing 851 is located away from one side of the moving plate 853. Finite block 854, the inner wall of the in-water housing 851 is provided with a moving ball 855, and a second through hole 856 is provided with a second through hole 856, which is fixedly coupled to a fixed cylinder 857, which is The fixing cylinder 857 is fixed from the side of the connecting post 850 fixedly connected to the cleaner 858, and the inlet housing 851 is in communication with the output of the telescopic hose and the water pump 10, the...

Embodiment 3

[0039] See Figure 2-6 The present invention provides a technical solution based on the first embodiment: a self-cleaning solar power generation plate, one end of the control mechanism 86 penetrates the support mounting plate 81 and securedly connected to the drive shaft of the circulation motor 87, and the control mechanism 86 includes directions. The rod 861, the side surface of the guide rod 861 fixedly coupled with positioning block 862, and a side surface of the positioning block 862 is fixedly coupled with a compression spring 863, and the side surface of the guide rod 861 is slidably connected to a clamping block 864, a compression spring 863. The connection is fixed to the connection post 851 from one end of the positioning block 862;

[0040] When used, the circulation motor 87 drives the control mechanism 86 to move, and the control mechanism 86 drives the clamping block 864 by the guide rod 861 to move the compression spring 863 to rotate the compression spring 863 to ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com