Installation method of riser clip on offshore jacket

An installation method and jacket technology, which is applied in the post-installation field of riser clips, can solve the problems of difficulty in installing work tools, inconvenient installation, and heavy weight of standpipe clips, and achieve the effects of shortening the construction period, improving efficiency, and saving project costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

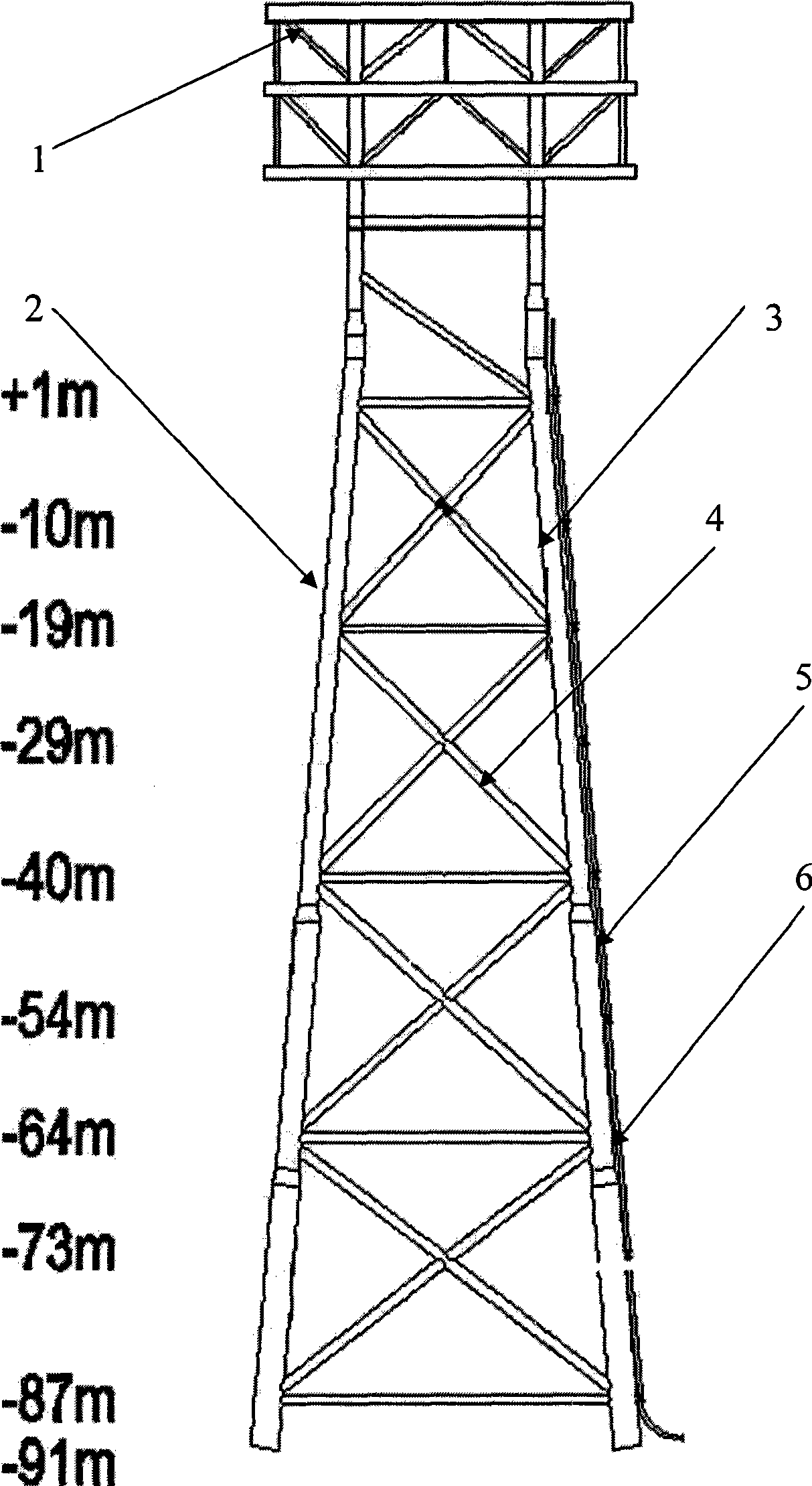

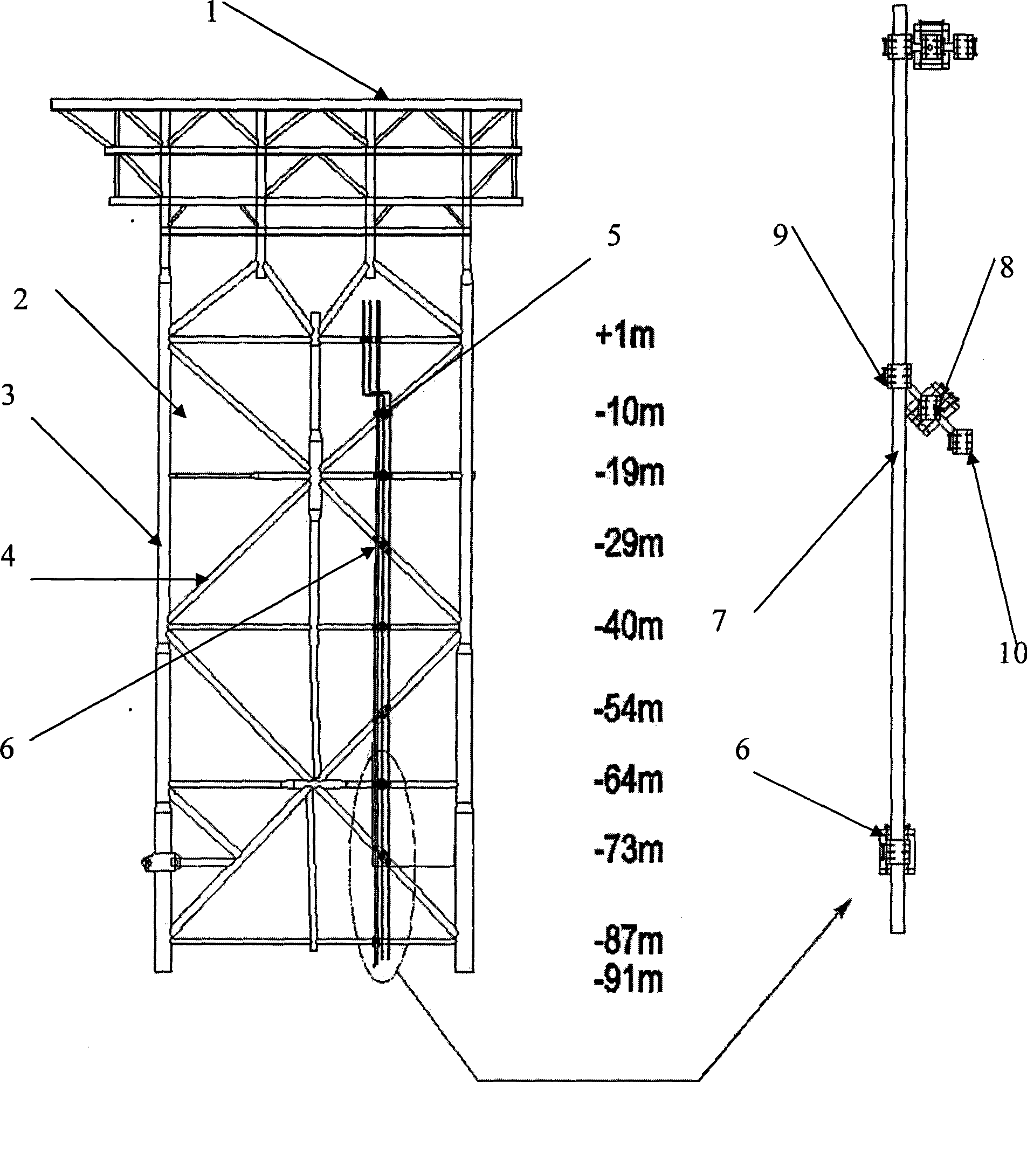

[0029] The installation method of the riser clip of the jacket of the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments:

[0030] Because in the installation method of the riser clips of the jacket of the present invention, the side views of the jacket, the riser and the clips are the same as those of the prior art, so they are not repeated.

[0031] In a specific embodiment of the installation method of the riser clips of the jacket of the present invention, it is necessary to use heliox diving to install 9 sets of riser clips on the platform,

[0032] like figure 2 As shown, in the installation method of the standpipe clips of the jacket of the present invention, the jacket 2 is composed of pile pipes 3 and tendon pipes 4, and the pile pipes 3 support the jacket 2 in the vertical direction, and are vertical on the left and right sides, but Slightly tilted forward and backward, resulting in the jacke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com