Method for cleaning a grinding body coated with cubi boron nitride and apparatus for performing said method

A technology of cubic boron nitride and abrasive tools, applied in cleaning methods and tools, cleaning methods using liquids, cleaning methods using gas flow, etc., can solve the problems of shortening the service life of abrasive tools, expensive structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Further preferred features and embodiments of the invention can be seen from the subclaims and the detailed description which follow. Two particularly preferred embodiments and methods will be described in detail below with reference to the accompanying drawings.

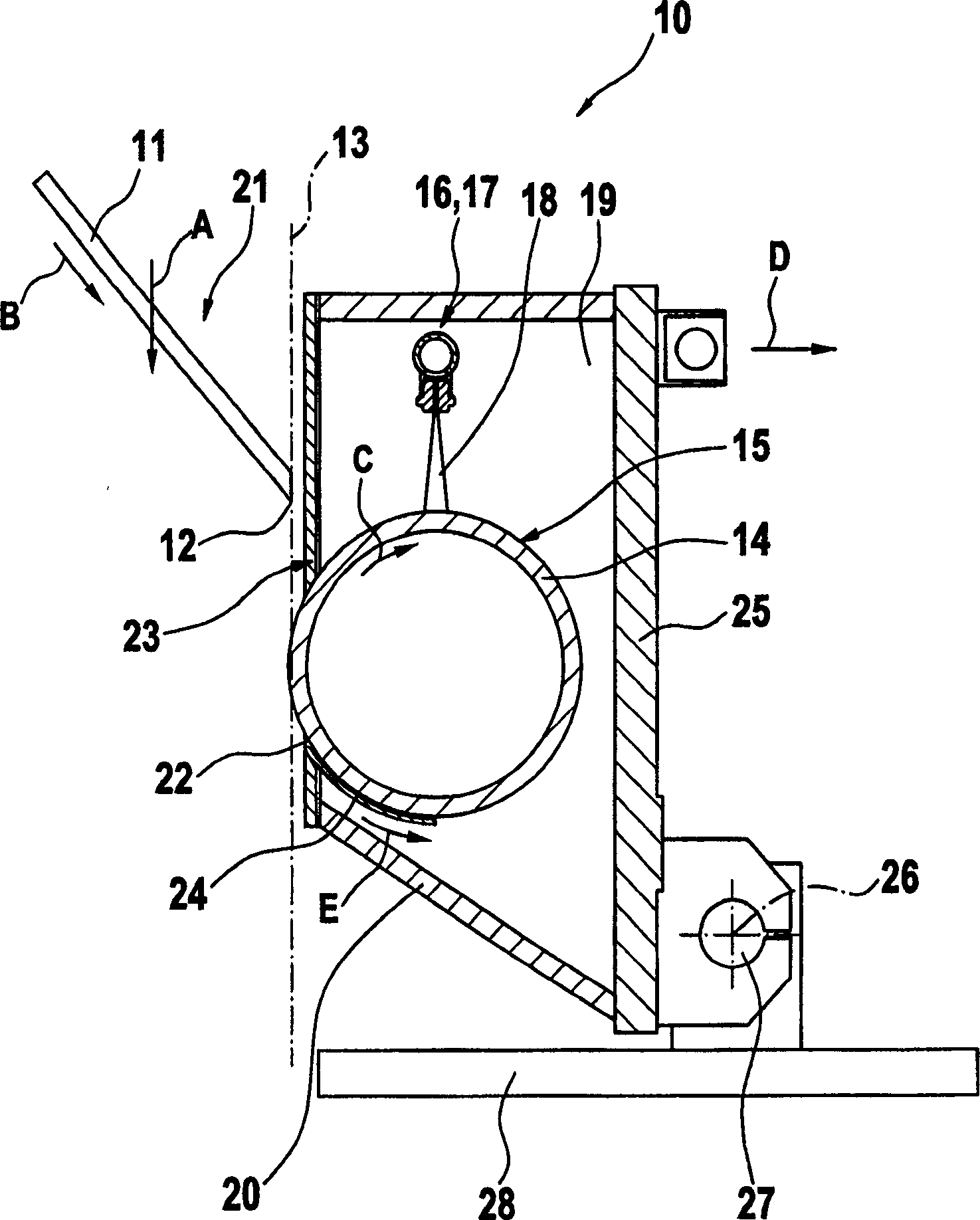

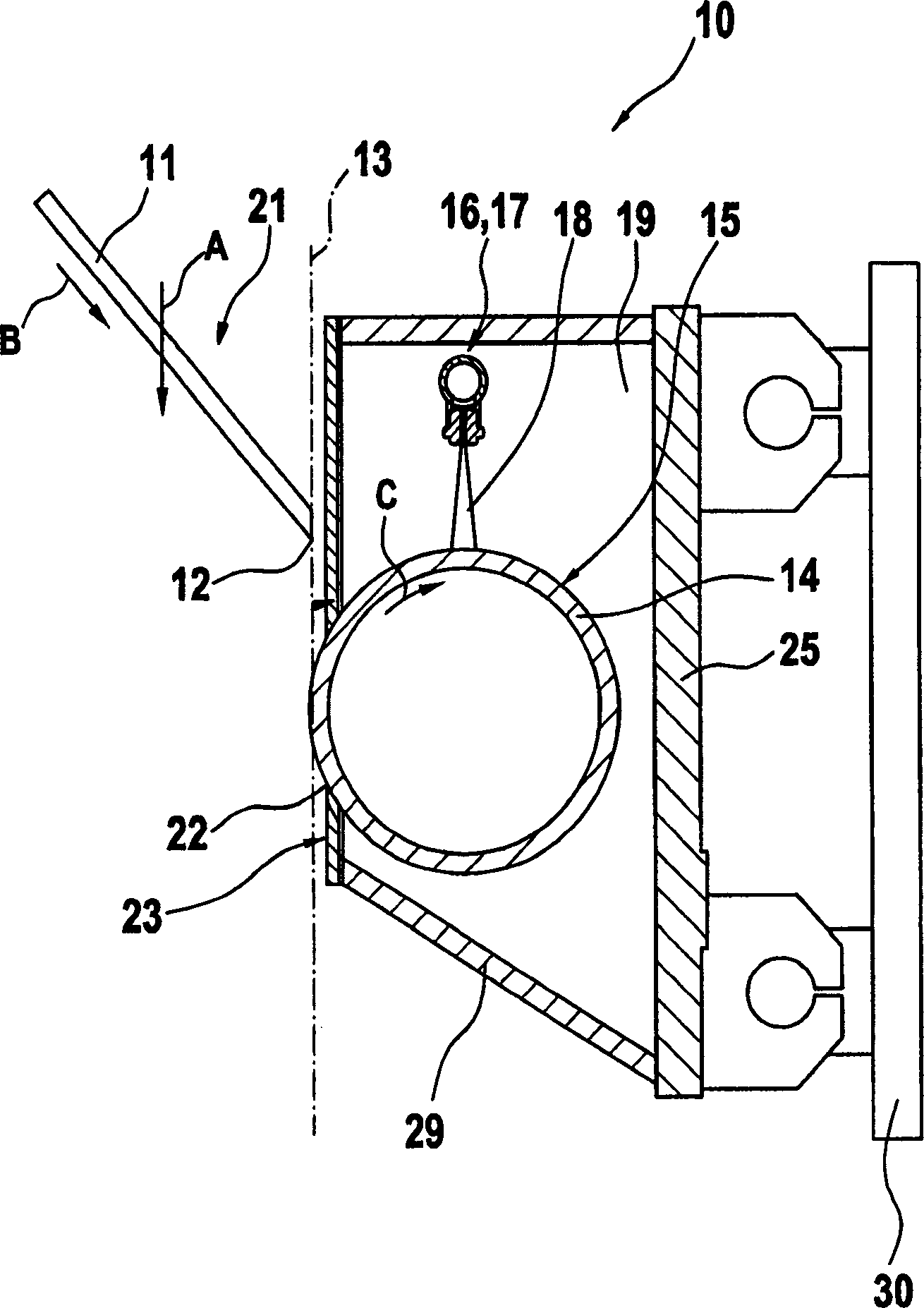

[0016] The apparatus shown is used to clean cubic boron nitride coated abrasives used for grinding tobacco cutting knives in a tobacco cutting machine.

[0017] figure 1 The device 10 shown in Fig. 1 shows a cutting knife 11 of a device (not further shown) for separating tobacco leaves from tobacco cake. For separating the tobacco leaves, single or several cutting knives 11 may be arranged on a cutting plate for forming a front cutter, a cutting drum for forming a drum cutter, or other knife supports. Instead of the cutter, other separating elements with cutters can also be used. Preferably, the tips 12 of several cutting knives 11 define a cutting plane 13 . A grinder 14 is also arranged in the region of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com