A die closing upsetter and a working method

A working method and upsetting machine technology, applied in upsetting presses, swaging presses, forging/pressing/hammering machines, etc., can solve problems such as troublesome debugging, difficulty in high-speed upsetting, high coordination requirements, etc., and achieve improvement The effect of upsetting forging efficiency, improving work efficiency and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] In this embodiment, the specific structure and working method of the die-clamping upsetting machine will be described by using the one-touch-one-punch die-clamping upsetting machine.

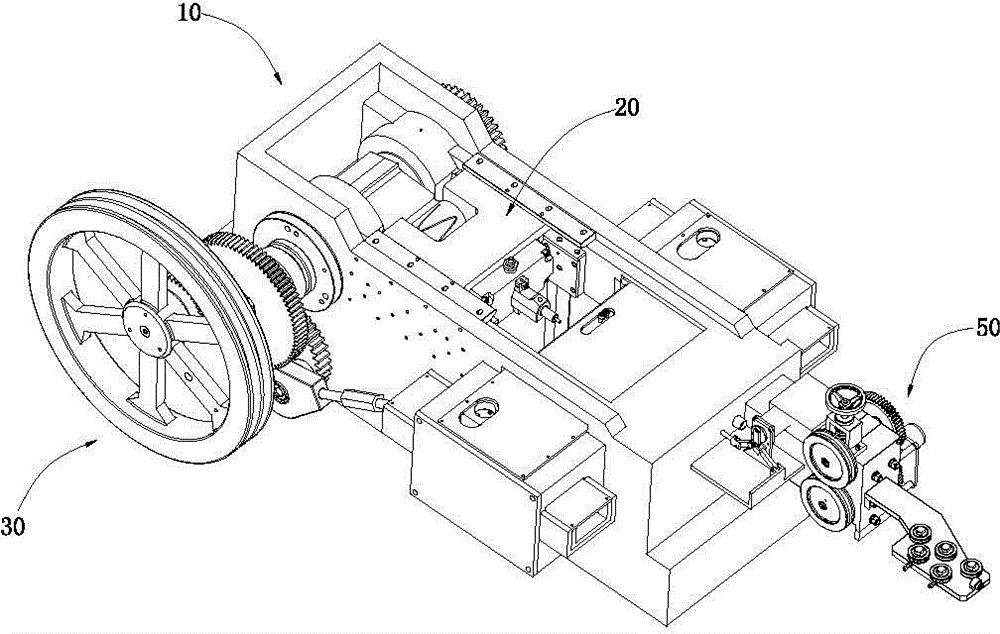

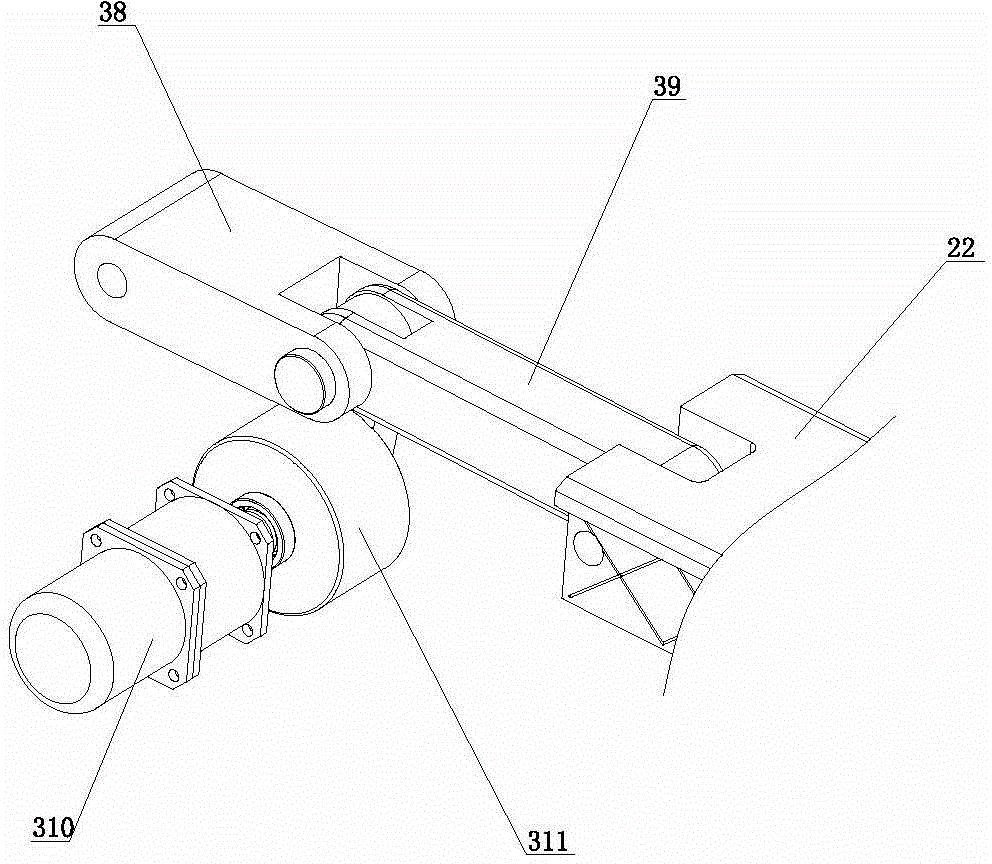

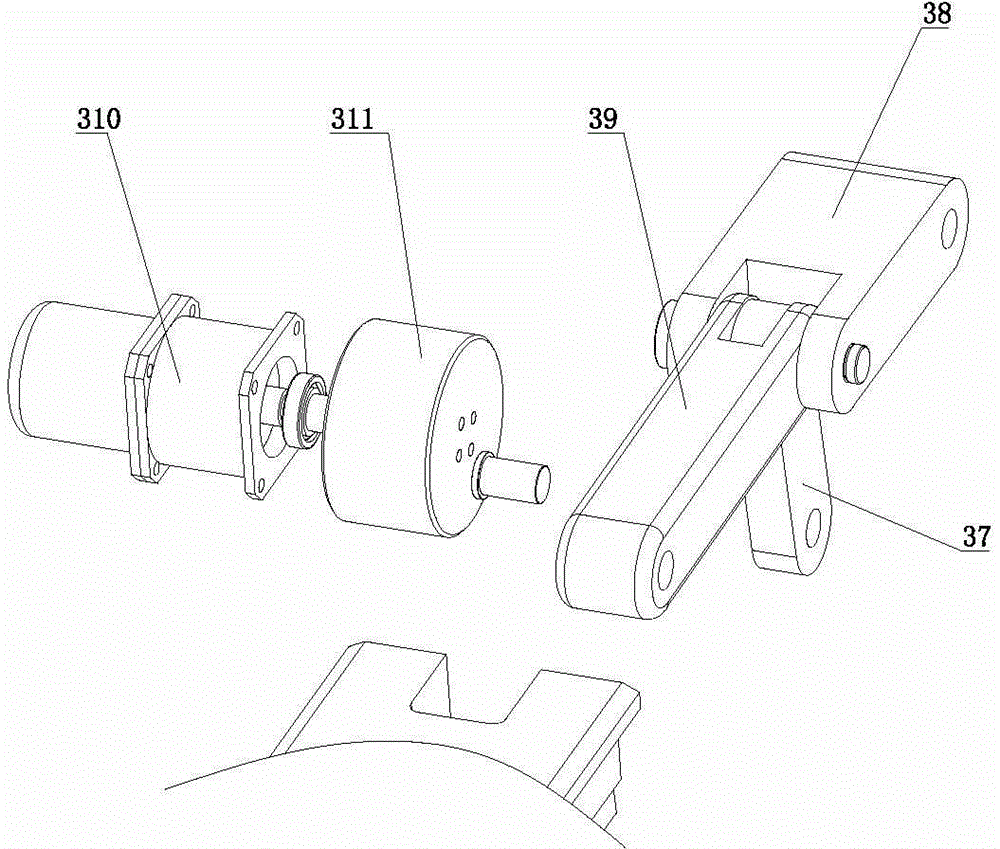

[0067] Such as figure 1 , figure 2 and image 3 As shown, the die-clamping upset forging machine includes a body 10, a punch assembly 20 installed on the body 10, a punch assembly driving mechanism 30 for driving the punch assembly 20, a feeding mechanism 50 arranged on the body 10, and a mold clamping assembly 90.

[0068] Such as figure 2 and image 3 As shown, the body 10 includes a frame 11, a base body 12 and a cover plate 13; the frame 11 includes a frame body 111 and a frame seat 112, and the frame seat 112 includes a frame body 1122 and an end plate 1123 , the base body 1122 has an accommodating cavity 1121 , the two ends of the accommodating cavity 1121 have openings 11211 , and the end plates 1123 are fixed on the base body 1122 at the openings. In this embodiment, the t...

Embodiment 2

[0099] In this embodiment, the specific structure and working method of the die-clamping upsetting machine will be described by using the one-touch-one-punch die-clamping upsetting machine.

[0100] Such as figure 1 , figure 2 and image 3 As shown, the die-clamping upset forging machine includes a body 10, a punch assembly 20 installed on the body 10, a punch assembly driving mechanism 30 for driving the punch assembly 20, a feeding mechanism 50 arranged on the body 10, and a mold clamping assembly 90.

[0101] Such as figure 2 and image 3 As shown, the body 10 includes a frame 11, a base body 12 and a cover plate 13; the frame 11 includes a frame body 111 and a frame seat 112, and the frame seat 112 includes a frame body 1122 and an end plate 1123 , the base body 1122 has an accommodating cavity 1121 , the two ends of the accommodating cavity 1121 have openings 11211 , and the end plates 1123 are fixed on the base body 1122 at the openings. In this embodiment, the t...

Embodiment 3

[0153] In this embodiment, the specific structure and working method of the die-clamping upsetting machine will be described by using the one-touch-one-punch die-clamping upsetting machine.

[0154] Such asfigure 1 , figure 2 and image 3 As shown, the die-clamping upset forging machine includes a body 10, a punch assembly 20 installed on the body 10, a punch assembly driving mechanism 30 for driving the punch assembly 20, a feeding mechanism 50 arranged on the body 10, and a mold clamping assembly 90.

[0155] Such as figure 2 and image 3 As shown, the body 10 includes a frame 11, a base body 12 and a cover plate 13; the frame 11 includes a frame body 111 and a frame seat 112, and the frame seat 112 includes a frame body 1122 and an end plate 1123 , the base body 1122 has an accommodating cavity 1121 , the two ends of the accommodating cavity 1121 have openings 11211 , and the end plates 1123 are fixed on the base body 1122 at the openings. In this embodiment, the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com