A fixed pipe support

A pipeline support, fixed technology, applied in the direction of pipeline support, pipe/pipe joint/pipe fitting, mechanical equipment, etc., can solve the problems of lack of direct adjustment, installation, high manufacturing cost, and larger production, so as to reduce pipeline adjustment. work, strong application and promotion value, and the effect of highlighting substantive characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

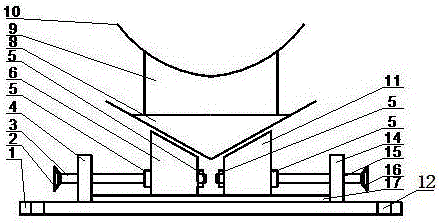

[0015] In order to clearly illustrate the technical characteristics of this solution, the following describes this solution through a specific implementation and in conjunction with the accompanying drawings.

[0016] It can be seen from the drawings that a fixed pipe support includes a bottom plate 1 on which a slide groove 17 is provided. The slide groove 17 can be formed by welding two parallel steel strips on the bottom plate 1. The sliding groove 17 has a left slider 6 and a right slider 11, the bottom surface of the left slider 6 and the bottom surface of the right slider 11 are in contact with the bottom plate 1, and the side surfaces of the left slider 6 and the right slider 11 are respectively in contact with There is a certain gap between the side surfaces of the sliding groove 17 to ensure that the left slider 6 and the right slider 11 can move flexibly in the sliding groove 17 without being stuck. The left slider 6 and the right slider 11 are both connected with a hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com