Biomass center air jet burner

a technology of biomass and air jets, which is applied in the direction of lighting and heating apparatuses, combustion types, and combustion using lumps and pulverizing fuels, etc., can solve the problems of reducing the heat output of biomass fuels, requiring considerably more fuel mass to achieve the effect of a comparable heat output, and affecting the combustion efficiency of biomass fuels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

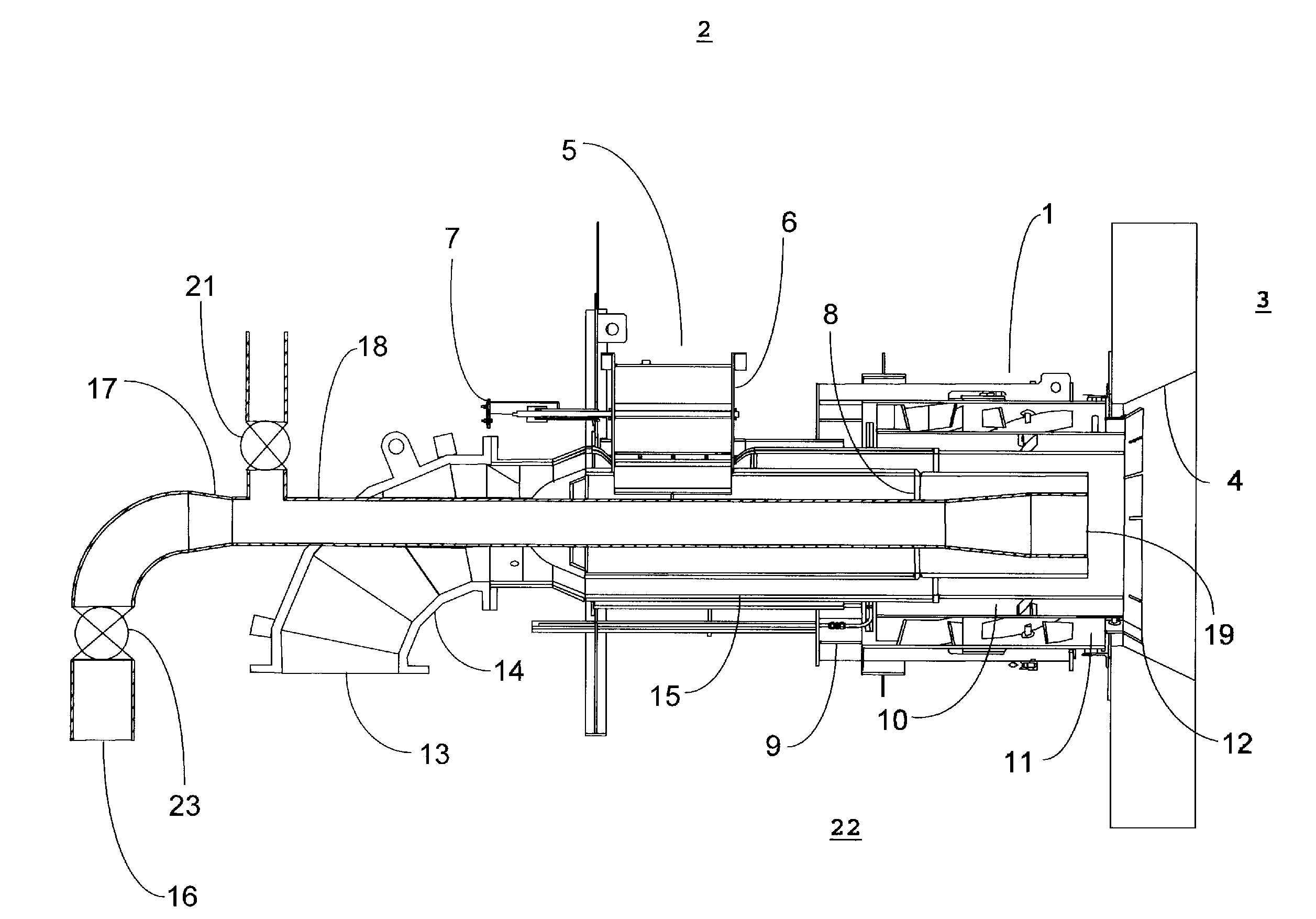

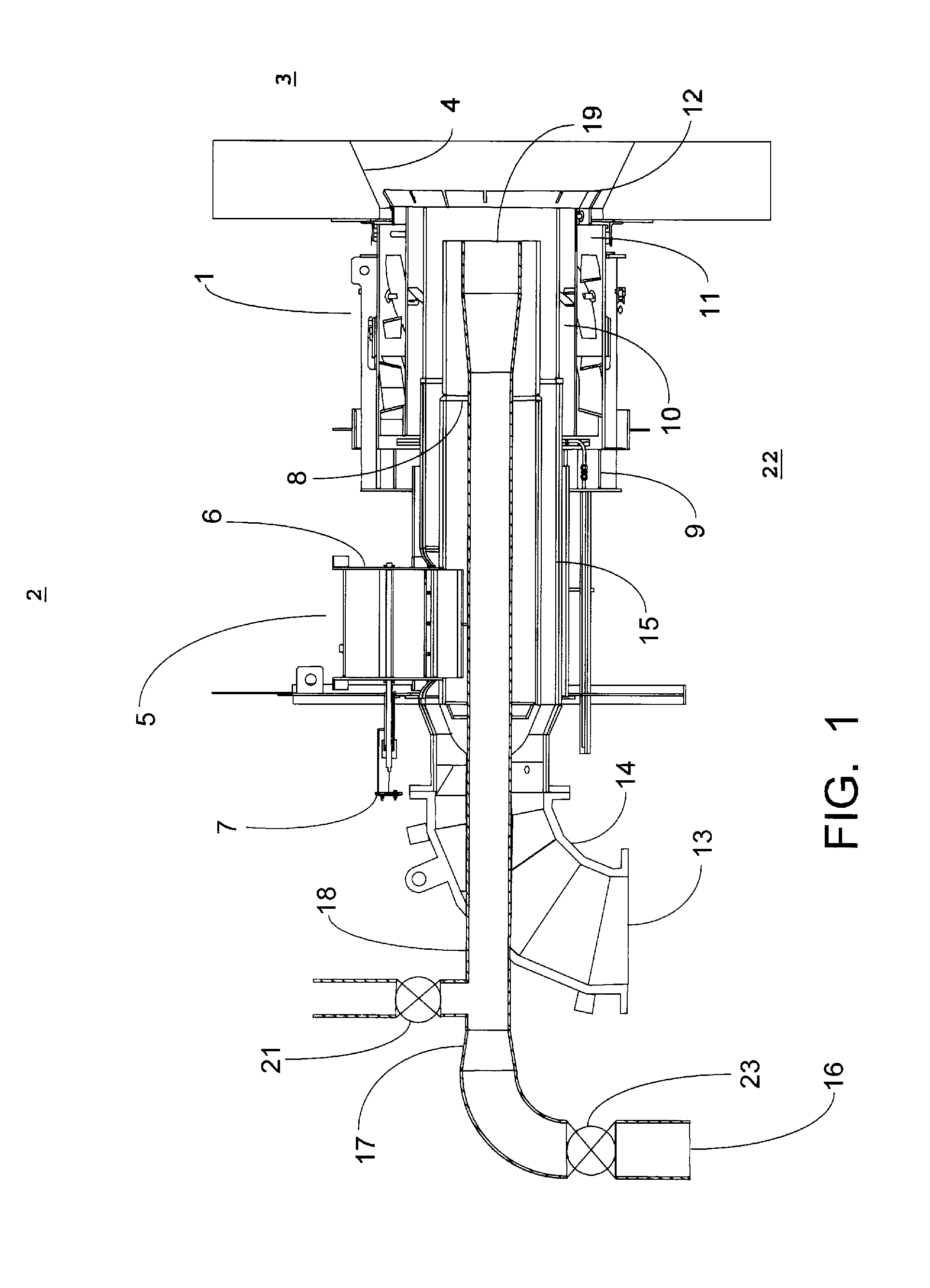

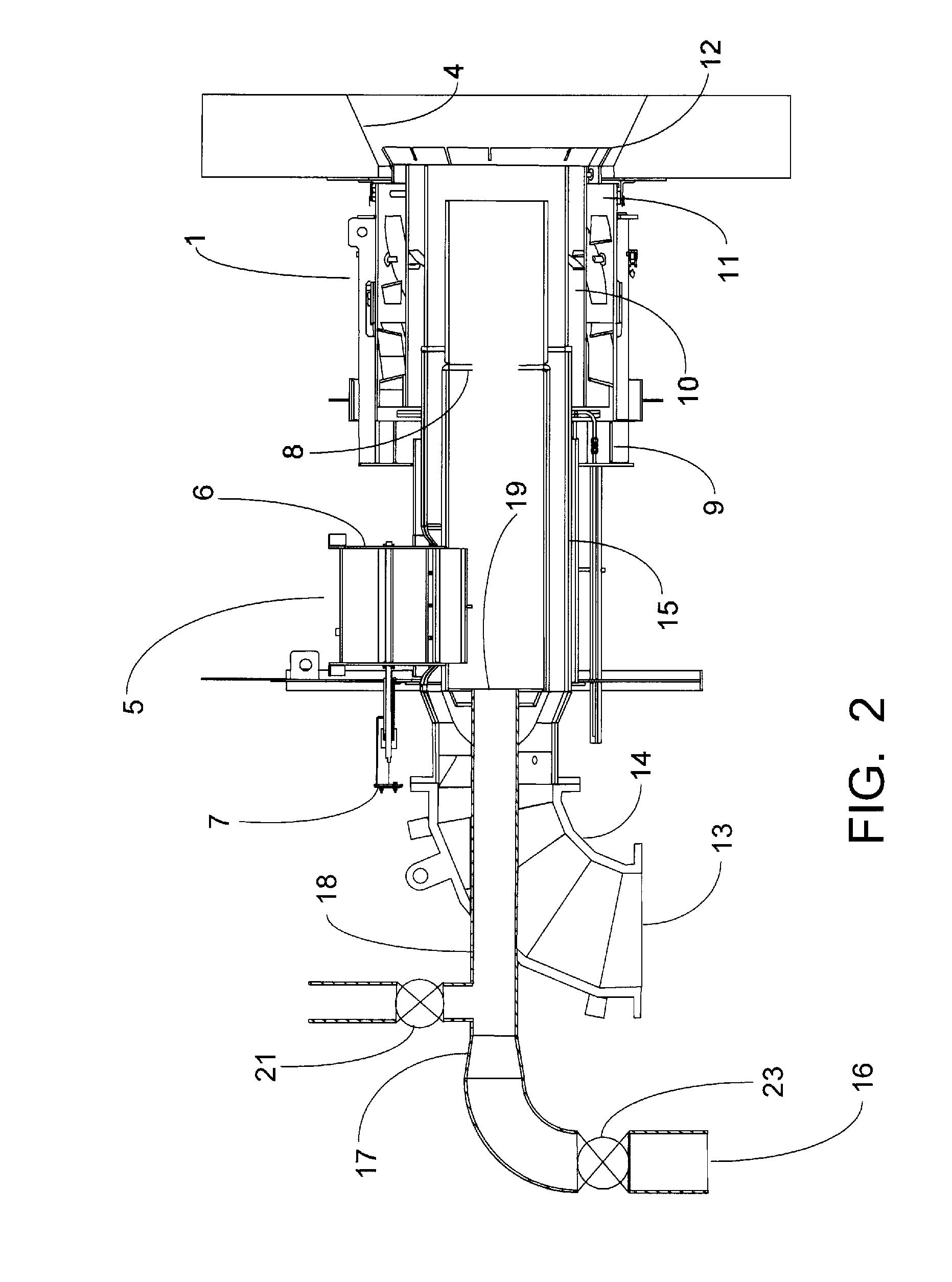

[0024]Referring now to figures, wherein like references designate the same or functionally similar elements throughout the several drawings, FIG. 1 shows a burner assembly 1 residing within windbox 2, which is attached to the furnace 3 of a boiler (not shown). Secondary air 22 is provided to windbox 2 by a forced draft fan (not shown) and heated by an air preheater (not shown). The burner assembly 1 is connected to furnace 3 by burner throat 4, through which air and fuel supplied to the burner assembly 1 are emitted into the furnace 3. A portion of the secondary air 22 constitutes core air 5. Core air 5 enters core air duct 6 and is regulated by core air damper 7. Core air 5 continues through the burner assembly 1 through core nozzle 8, exiting through the burner throat 4.

[0025]Secondary air 22 is also supplied to the burner assembly (designated as secondary air to the burner assembly 9). Secondary air 22 enters the burner assembly 1 and travels through parallel flow paths of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com