Biomass semi-gasification automatic control combustion engine

A semi-gasification and biomass technology, which is applied in the direction of combustion methods, combustion equipment, and solid fuel combustion, can solve the problems of secondary pollution automation, low combustion efficiency, and unstable combustion, and achieve efficiency improvement and reduction Carbon emissions, the effect of reducing carbon emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

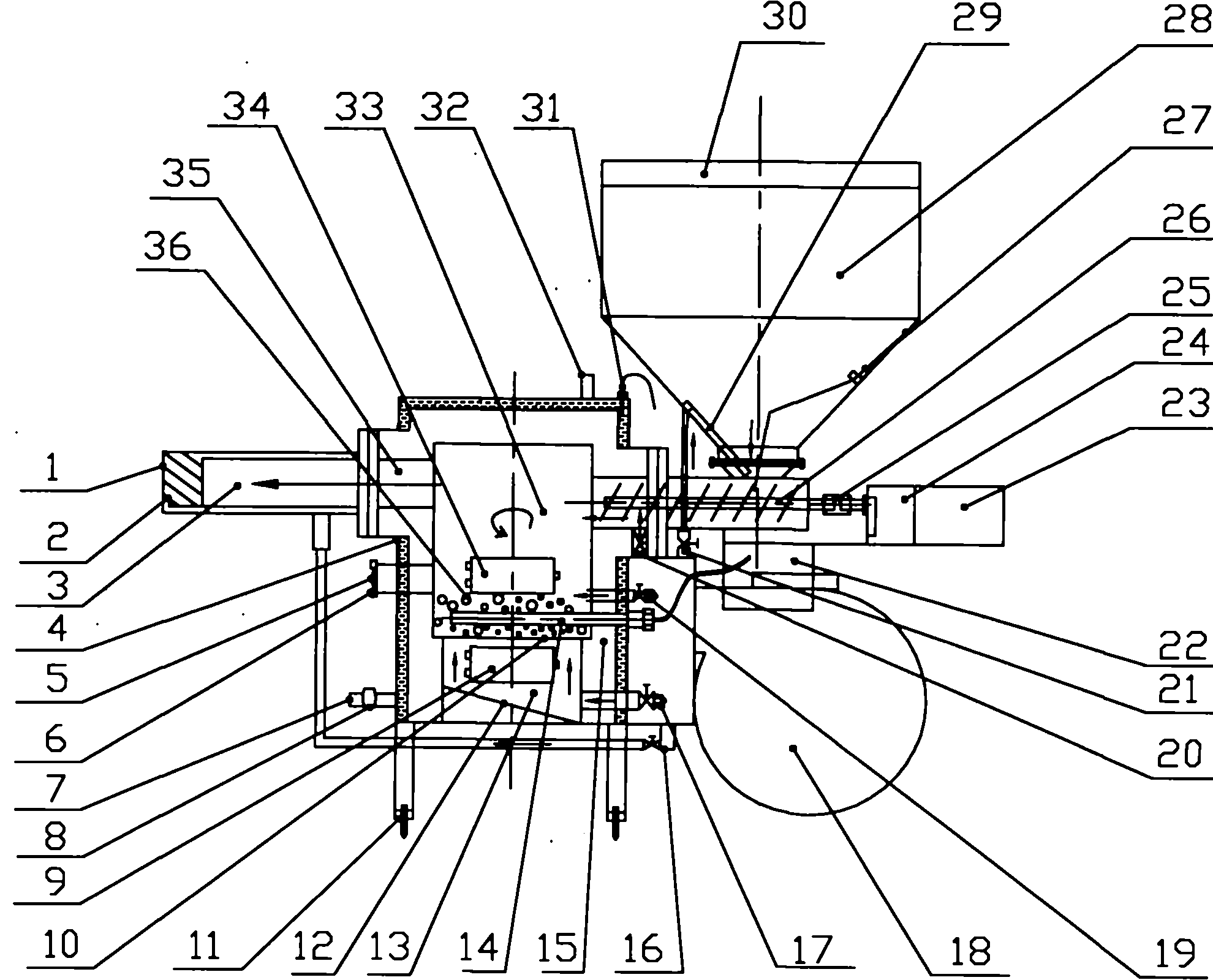

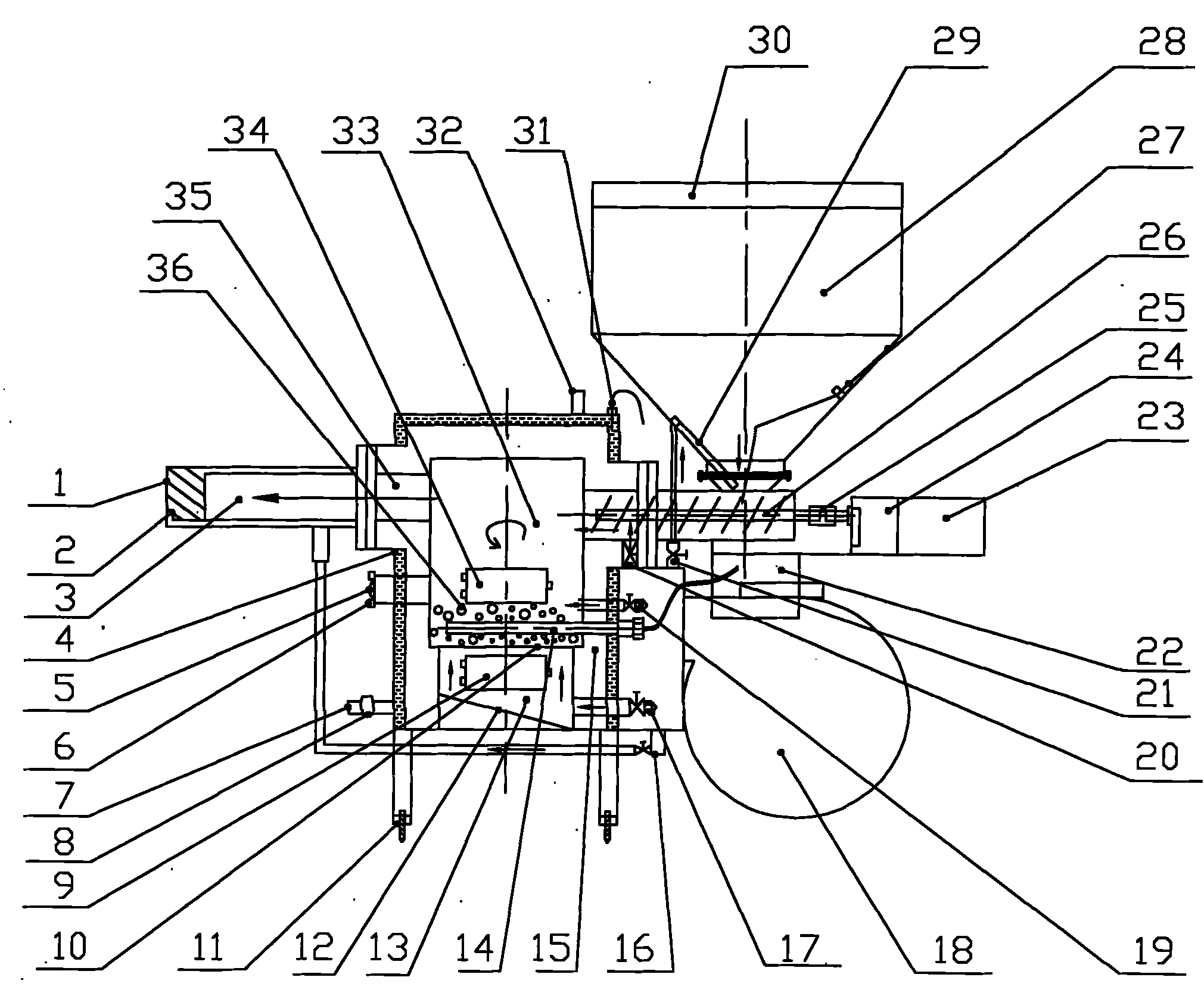

[0021] Such as figure 1 As shown, a semi-gasification combustion chamber 33 is formed inside the base of the present invention, and the fire grate 10 horizontally fixed inside the semi-gasification combustion chamber 33 divides the entire semi-gasification combustion chamber 33 into two cavity parts up and down. , the cavity above the grate 10 is the combustion cavity, and the cavity below the grate 10 is the ash cleaning cavity. Since several through holes are provided on the fire grate 10, the combustion chamber and the ash cleaning chamber are communicated through the through holes.

[0022] The burner 35 formed on the base communicates with the combustion chamber, and at the same time, the torch 3 communicates with the burner 35 through a threaded connection. To ensure that the torch 3 can be easily disassembled and replaced, in order to ensure the use effect, a spoiler 1 is uniformly welded at the mixing place 2 of the torch 3 tail cloth.

[0023] The feeding device for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com