Maple syrup evaporator with biomass burner

a biomass burner and evaporator technology, applied in the field of biomass burners, can solve the problems of high cost of wood or oil fuel, inefficiency in energy conversion, and environmental impact of the fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012]The present invention is illustrated in further details by the following non-limiting examples.

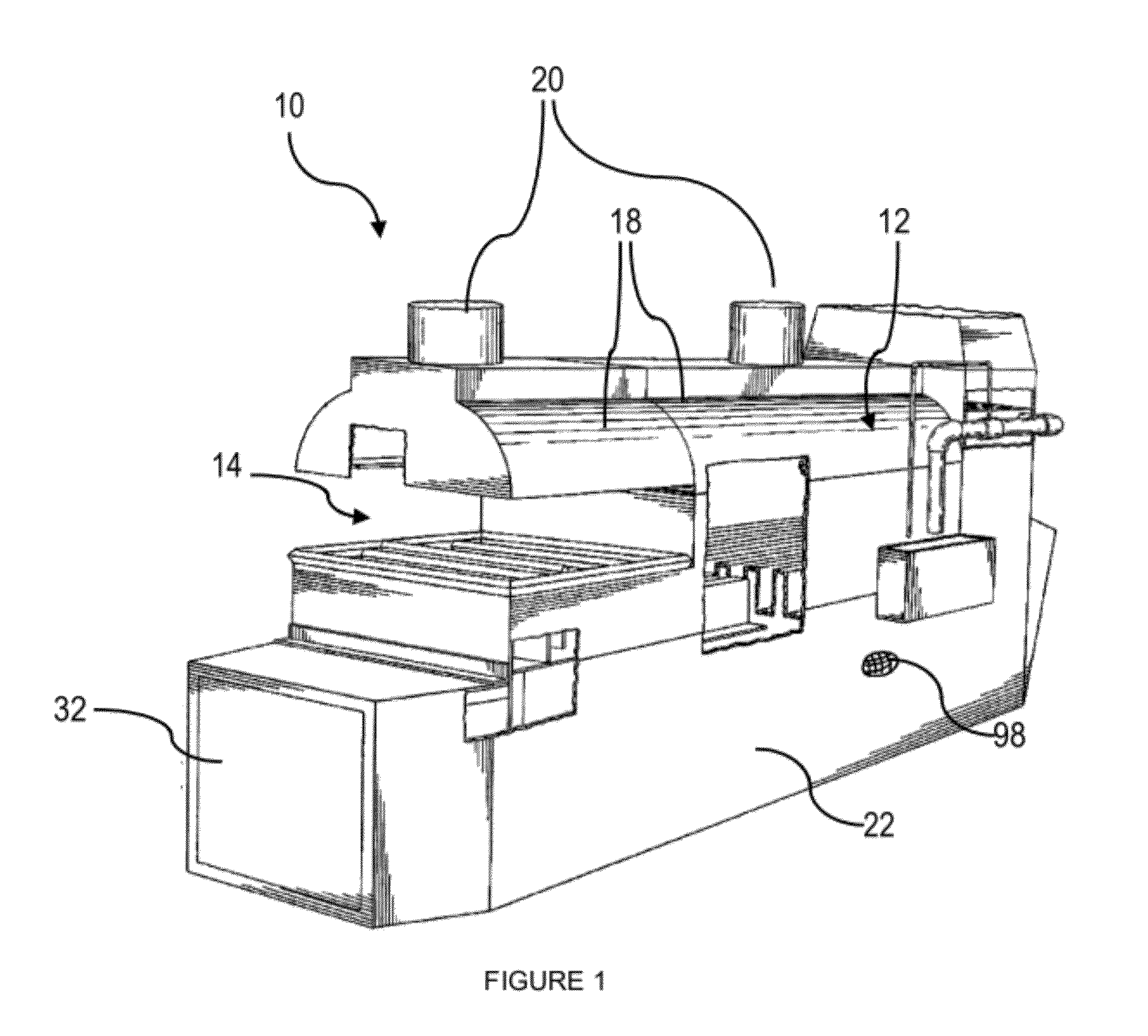

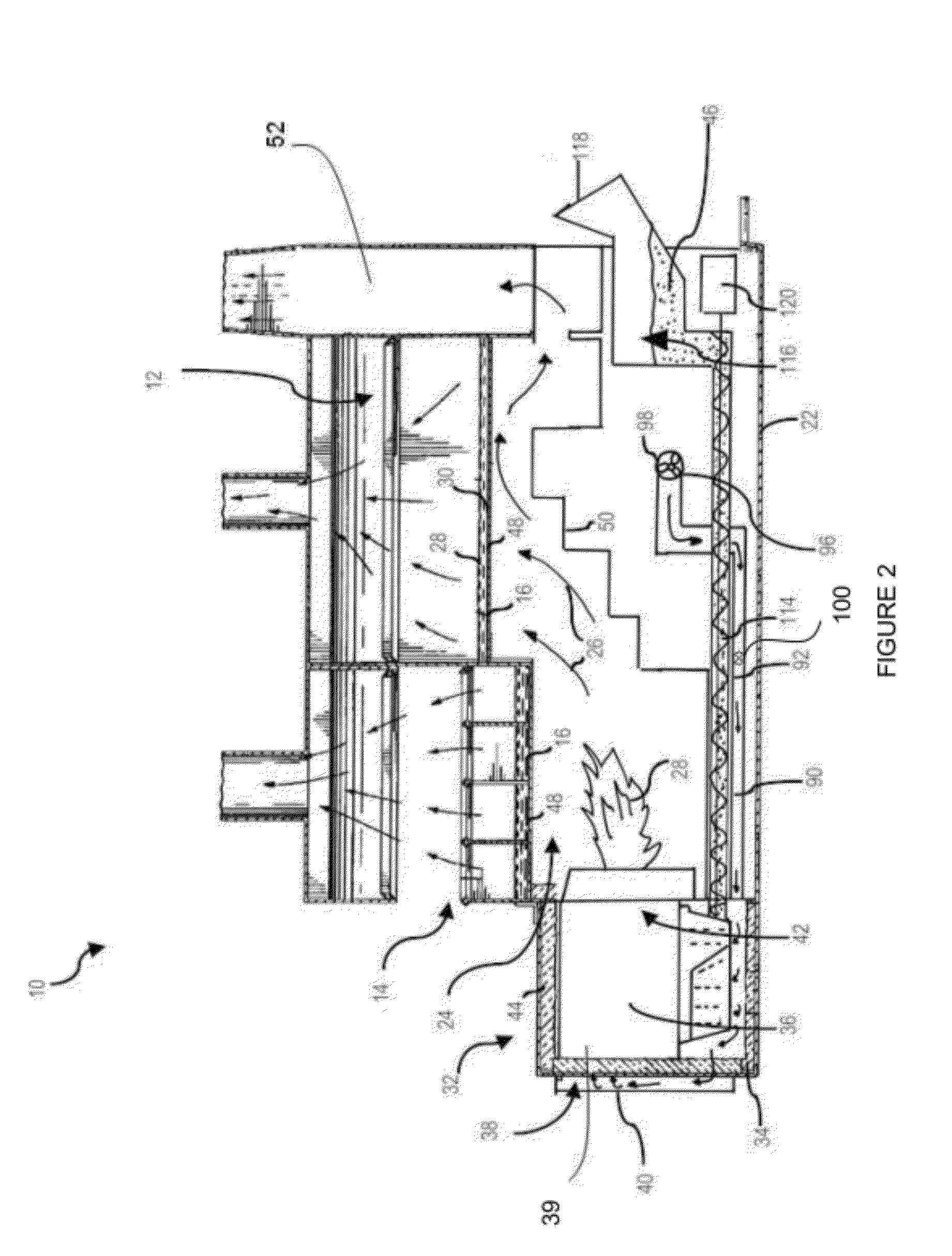

[0013]Now referring to FIG. 1, there is provided an evaporator for the evaporation of maple sap in the production of maple syrup generally referred to using the reference numeral 10. The evaporator comprises a maple sap evaporating section 12 and a maple syrup forming section 14 both illustratively comprising horizontally extending pans 16, which are shown in FIG. 2, provided with partitions in which maple sap travels. The evaporator 10 further comprises a hood as in 18 for each section 12, 14 and vapour outlets as in 20 for directing the water vapour evaporated from the sap to atmosphere.

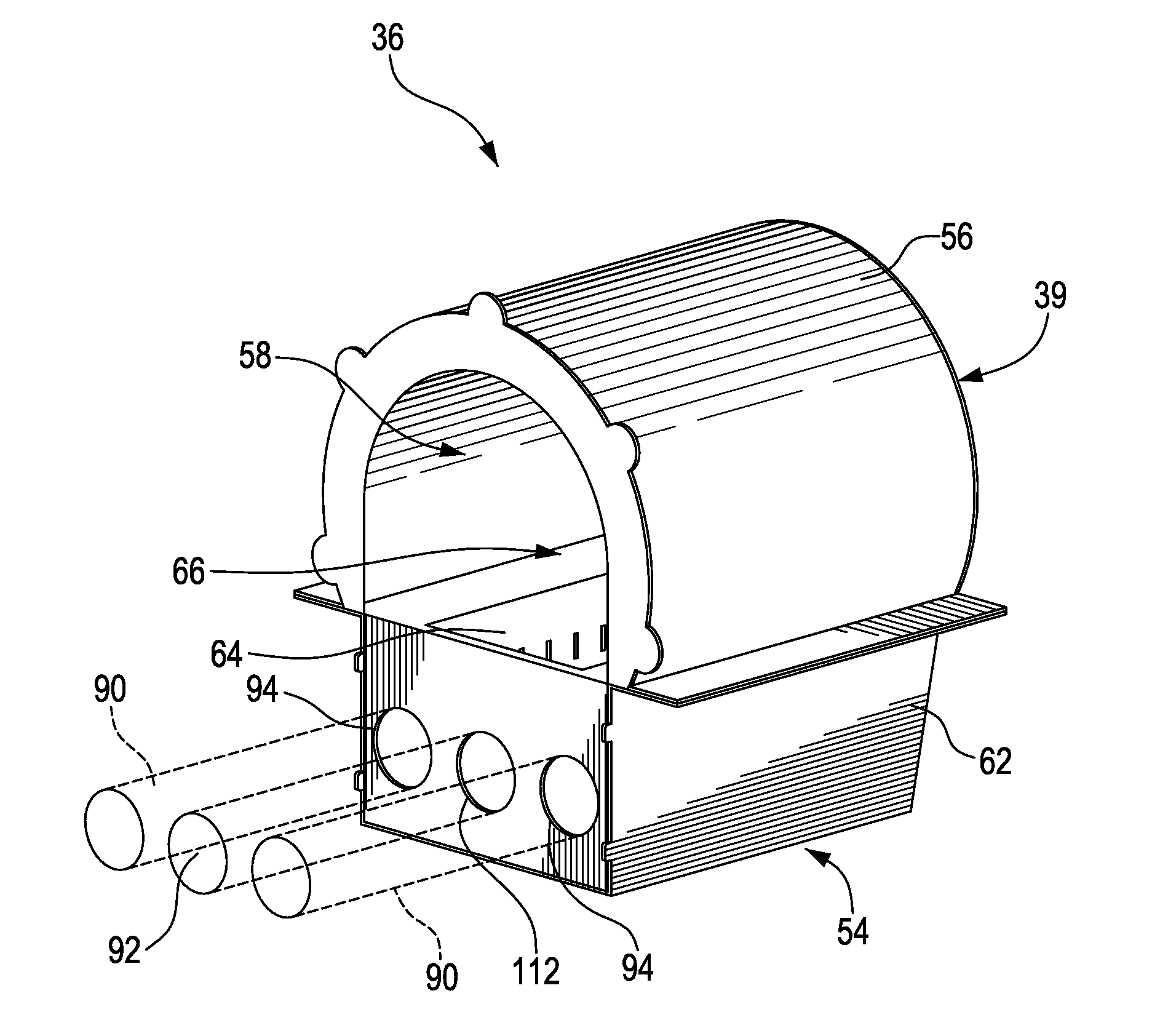

[0014]Now referring to FIG. 2, in addition to FIG. 1, extending beneath the maple sap evaporating section 12 and the maple syrup forming section 14 is a heating housing 22 comprising a heating chamber 24 for exposing heated air 26 and flames 28 to the undersides of the horizontally extending pans 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com