Combustion air vent control for furnaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]The invention will now be described in detail with reference to the attached drawing figures.

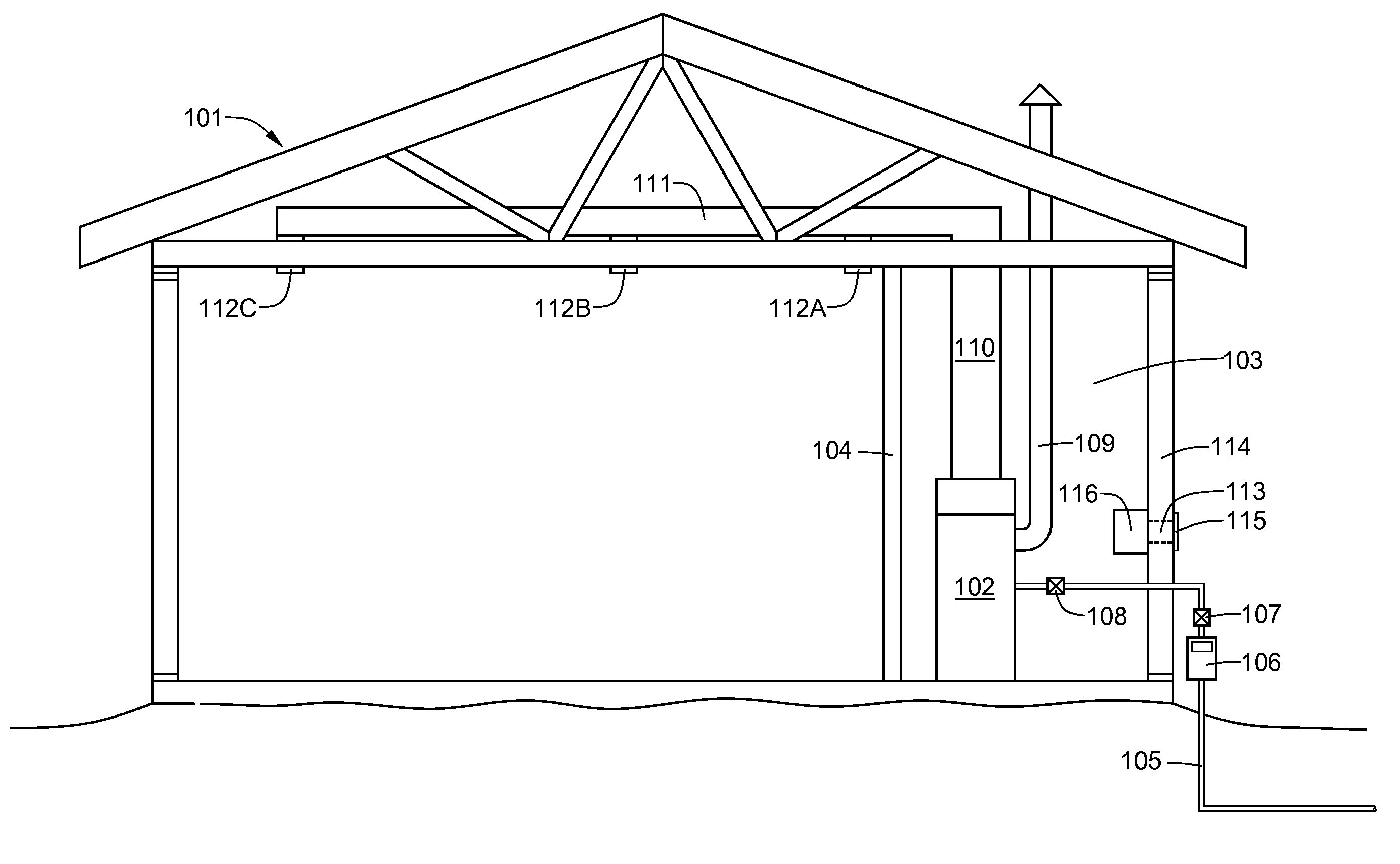

[0025]Referring now to FIG. 1, a cutaway view of a home 101 is shown, in which a combustion natural gas furnace 102 has been installed in the mechanical room 103. A wall 104 separates the mechanical room 103 from the rest of the house. A natural gas supply pipe 105 supplies natural gas to a meter 106. Natural gas is fed to the furnace 102 first through an exterior cut-off valve 107 and then through an interior cut-off valve 108 positioned near the furnace 102. An exhaust flue 109 transfers combustion products from the furnace 102 to outside the home 101. A vertical air duct 110 transports heated air from the furnace 102 to a horizontal air duct 111 in the ceiling, from which the heated air is expelled from various ceiling registers 112A, 112B, and 112C. A combustion air vent 113 provides combustion air from the exterior of the house to the mechanical room 103. The furnace 102 then pull...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com