Burner

A combustion device and burner technology, which is applied in the direction of combustion method, combustion control, combustion equipment, etc., can solve the problems of air volume reduction, reference current value reduction, and inability to accurately obtain air volume, so as to reduce adjustment work and high-precision air volume correction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

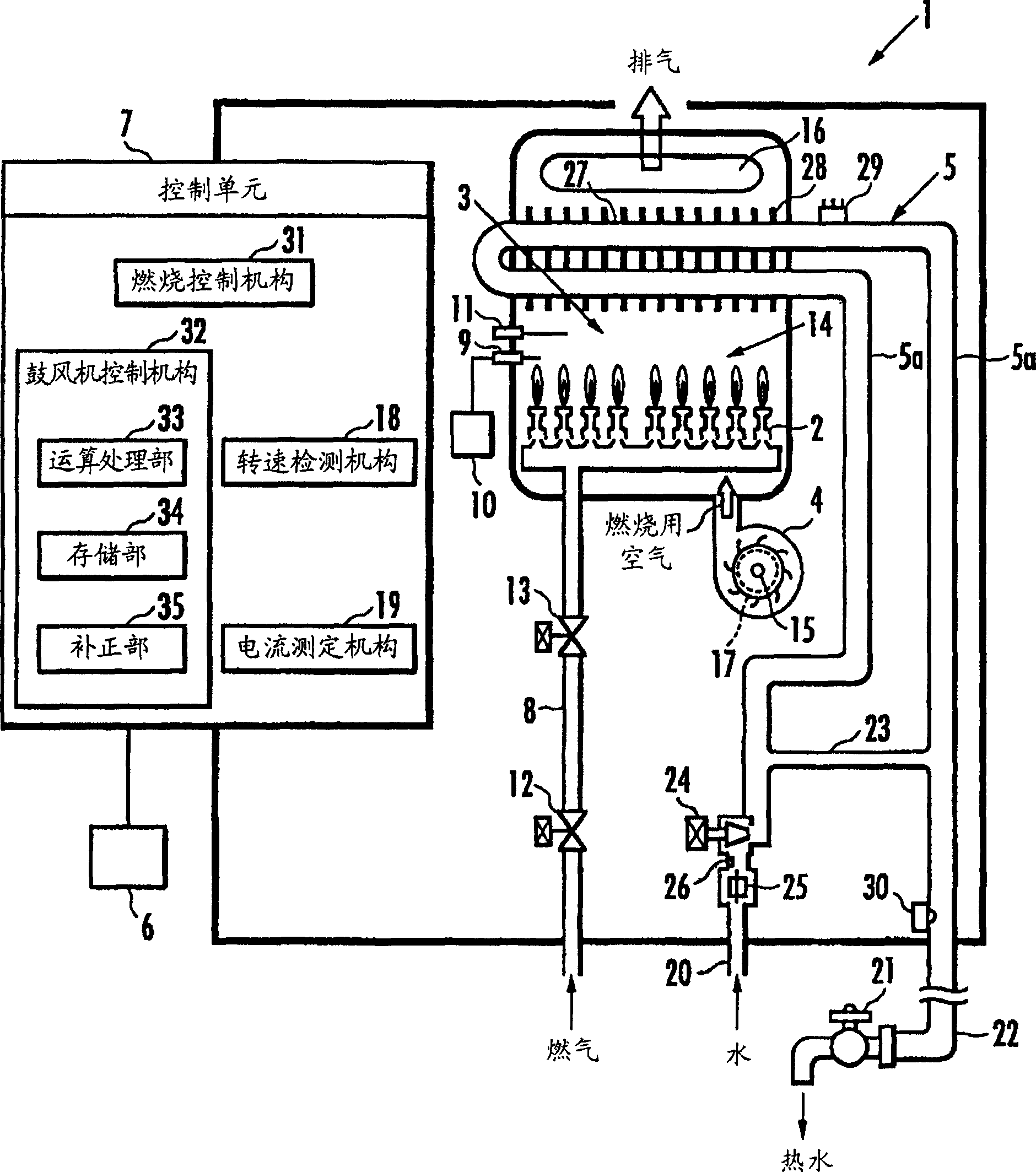

[0019] One embodiment of the present invention will be described with reference to the drawings.

[0020] figure 1 The combustion device 1 shown is a water heater, which has: a burner 2, a ventilation system 3, which includes the burner 2; a blower 4, which is arranged on the ventilation system 3 and can forcefully Combustion air is supplied to the burner 2; the water passage 5; and the control unit 7 which controls the hot water supply operation based on the setting of the hot water supply temperature by the remote controller 6 or the like.

[0021] The burner 2 is ignited and burned by igniting the gas supplied through the gas passage 8 through the ignition electrode 9 and through the igniter 10 ; the state of its combustion flame is detected by the flame detection rod 11 . On the gas passage 8, a main solenoid valve 12 and a speed regulating solenoid proportional valve 13 are sequentially arranged from upstream to downstream. The speed-regulating proportional solenoid val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com