Combustor

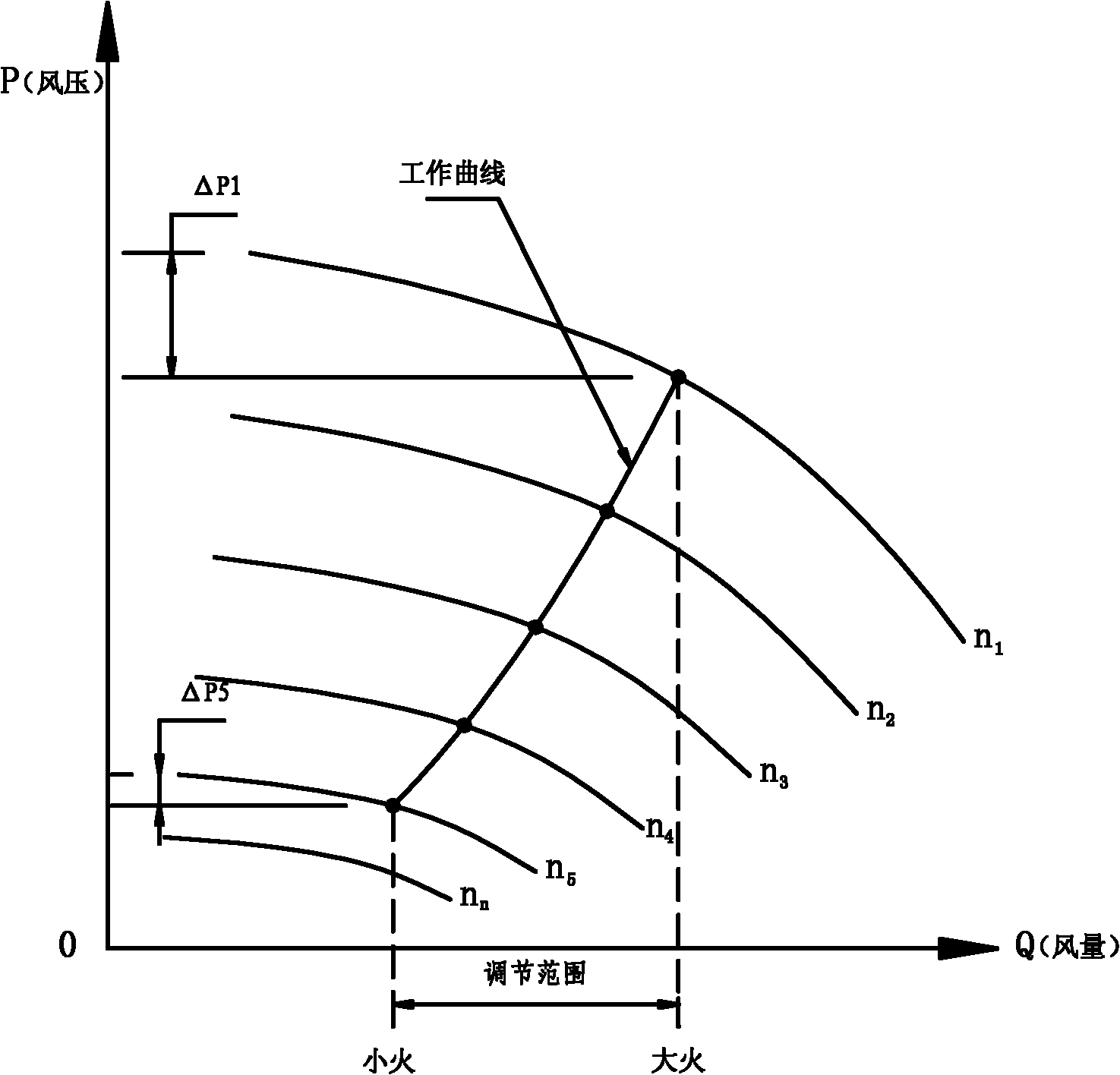

A burner and combustion head technology, applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve the problem of narrow firepower adjustment ratio range, and achieve the effect of widening the firepower adjustment ratio range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make those skilled in the art more clearly understand the purpose, technical solutions and advantages of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

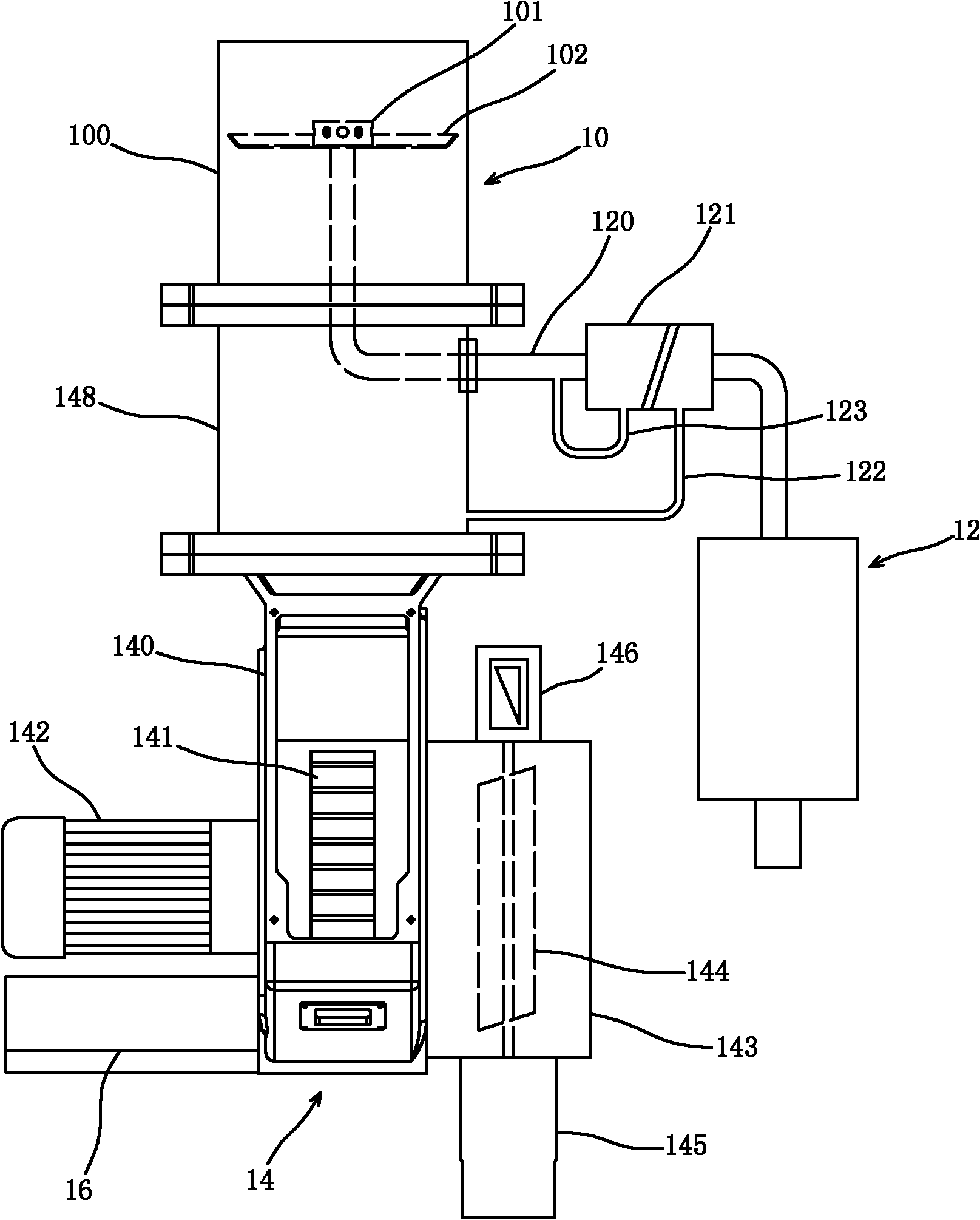

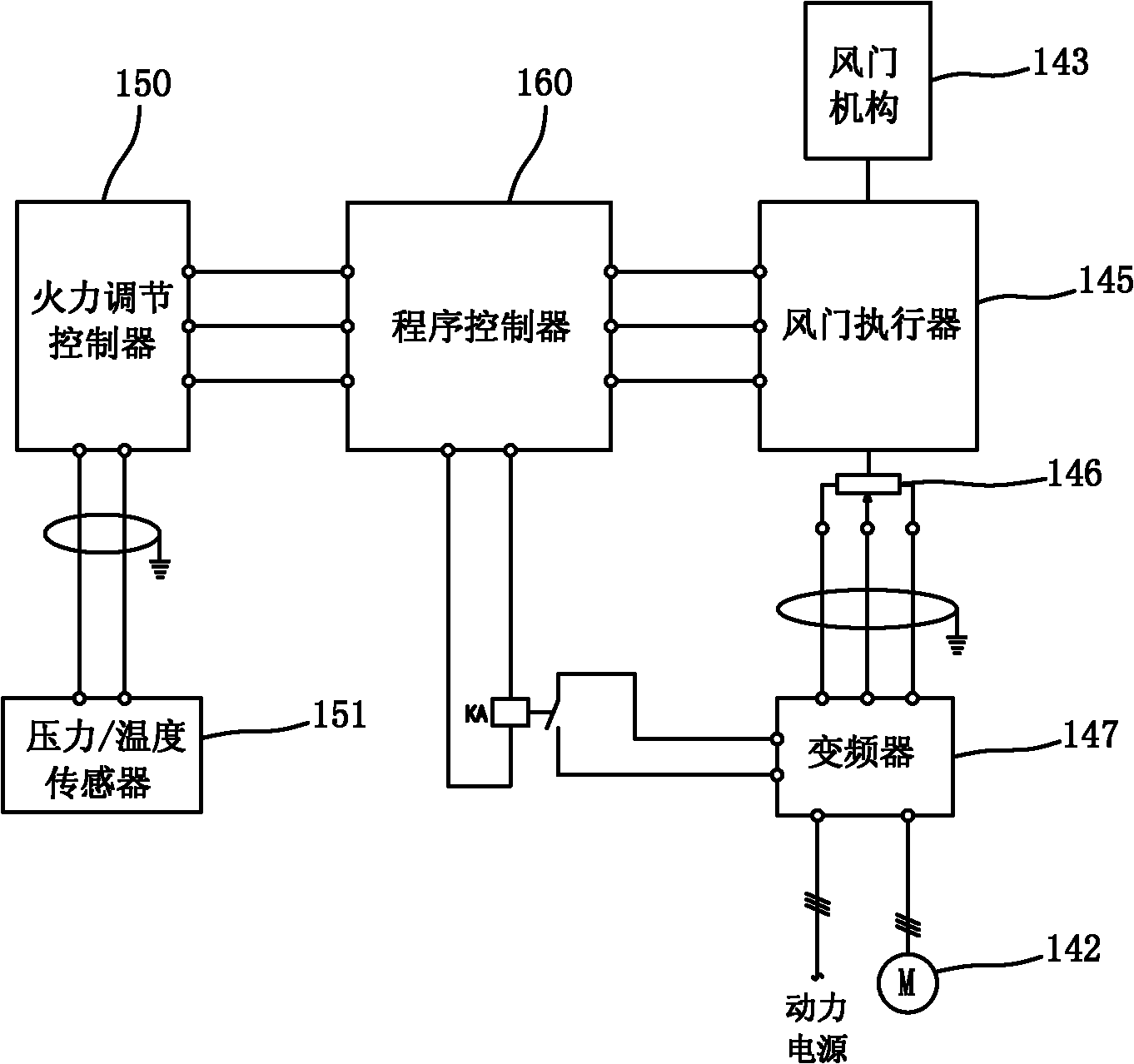

[0025] refer to Figure 2 to Figure 5 As shown, the burner disclosed in the present invention includes a combustion head 10, an igniter (not shown in the figure), a fuel delivery / adjustment device 12, a combustion air delivery / regulation device 14, a safe operation monitoring device (figure not shown in ) and an electric control device 16, the electric control device 16 is respectively connected with the igniter, the fuel delivery / regulation device 12, the combustion air delivery / regulation device 14, and the safety operation monitoring device to control the operation of the above-mentioned devices , and complete the automation of the burner.

[0026] The combustion head 10 includes a flame tube 100 and a nozzle 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com