Waste incineration treatment apparatus and treatment method thereof

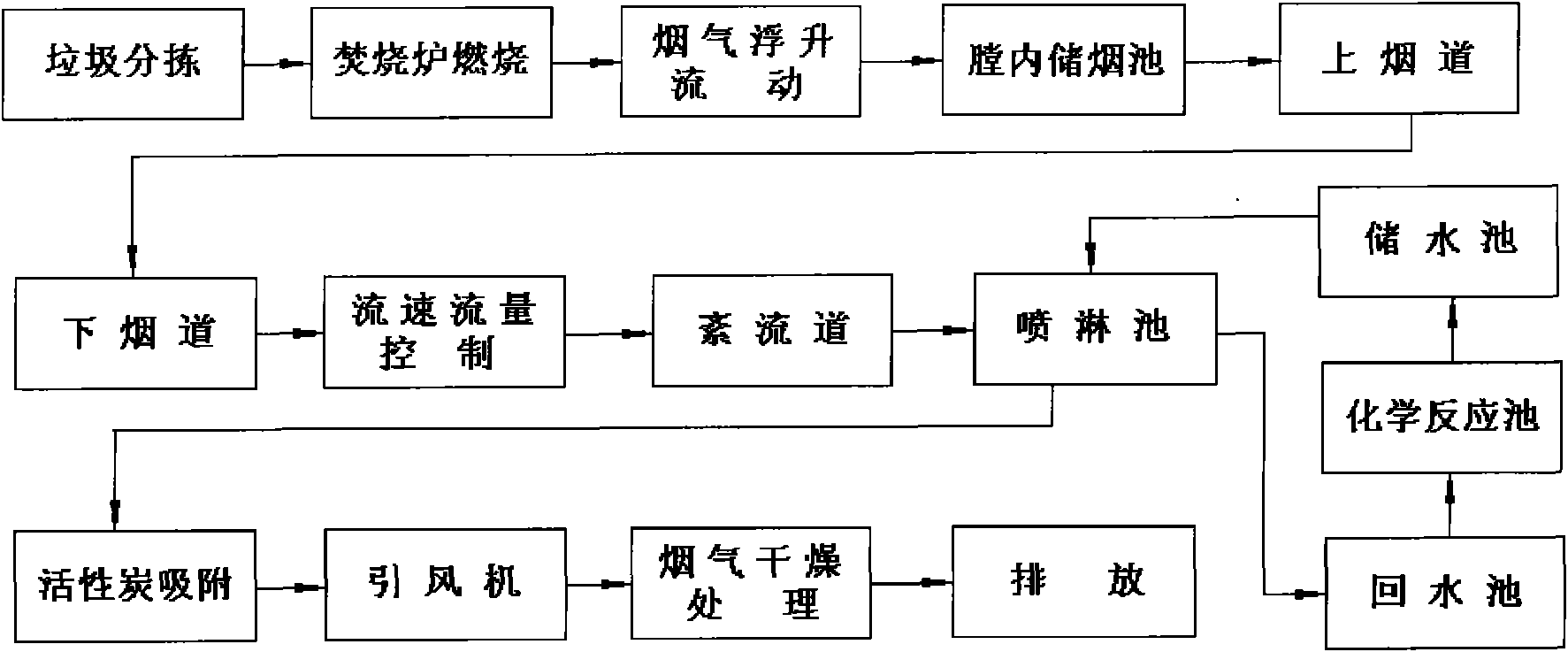

A technology of waste incineration and treatment device, which is applied to the treatment of waste incineration and treatment device, and the field of waste incineration treatment device, which can solve the problem of not easy to adsorb toxic gases and smoke, does not solve the problem of oxygen-enhancing and combustion-supporting waste, and fails to solve the problem of garbage, etc. To achieve the effect of harmless treatment, good drying effect and high thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

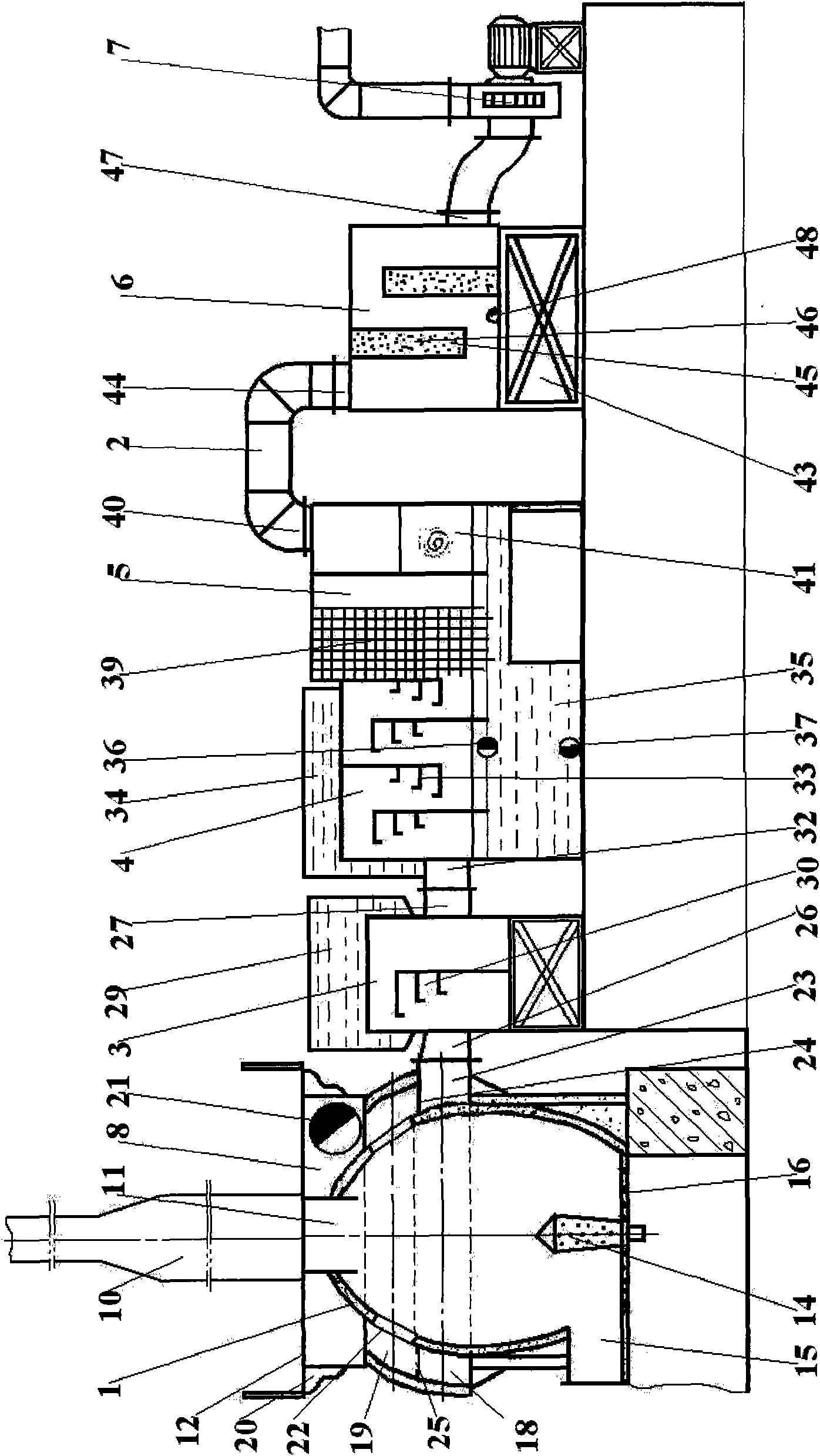

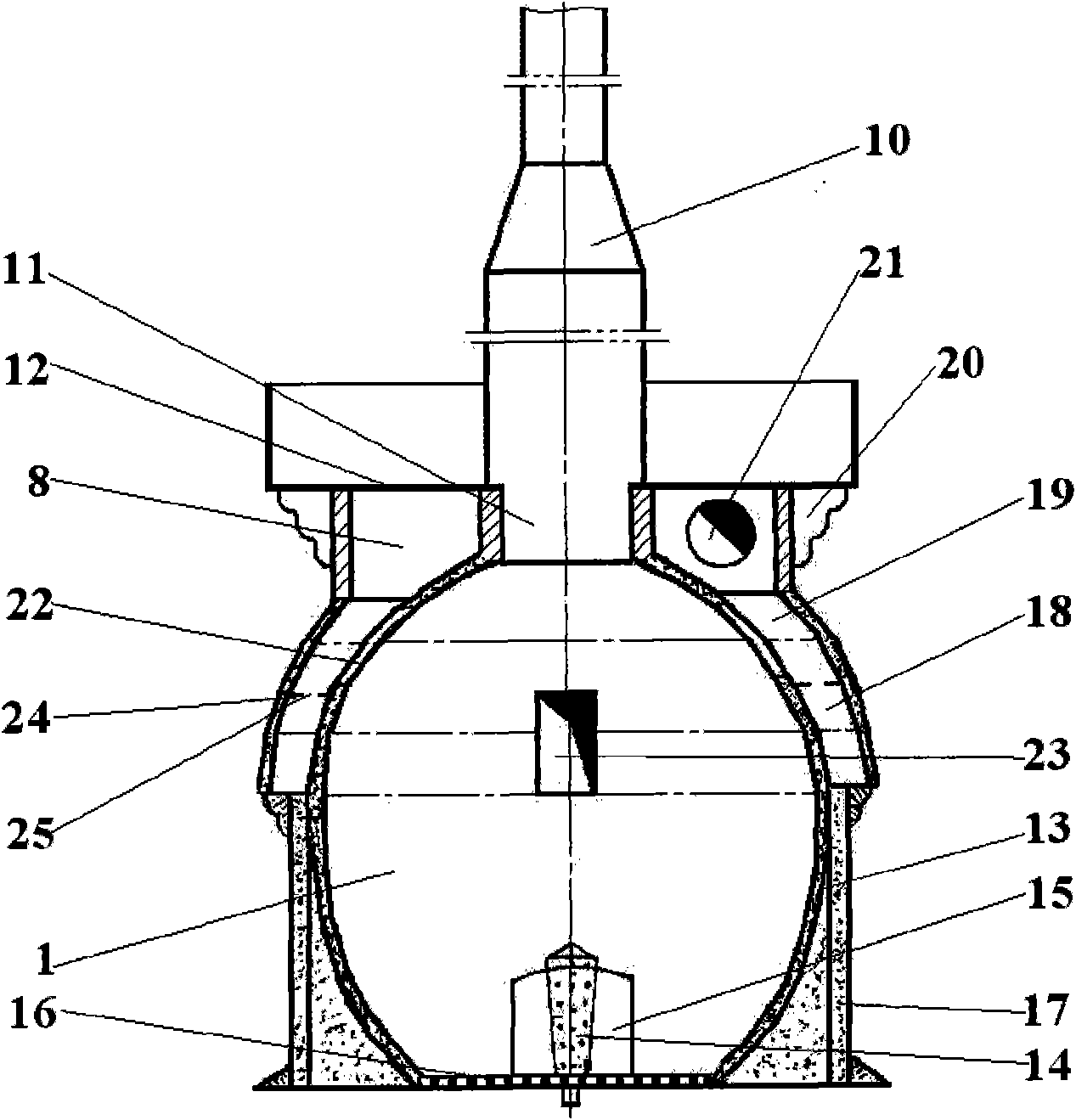

[0058] One, the structure of incinerator body 1, shape and the implementation example of arranging oxygen increasing pipe 14:

[0059] Such as figure 1 and image 3 As shown, the shape of the incinerator body 1 and the technical scheme for setting the oxygen increasing pipe 14: the shape of the vertical section of the incinerator body 1 is an approximate ellipse whose size in the up and down direction is greater than the size in the horizontal direction, and the shape of the incinerator body 1 The lower part is provided with the cast iron grate 16 for air intake, and is arranged in the horizontal direction, and rubbish is spread on the cast iron grate 16.

[0060] In addition, on the cast iron grate 16, where the garbage is not easily exposed to the air, an oxygen supply device for strengthening the garbage is also provided. Forced oxygen supply is implemented inside the center exposed to fresh air, so that the interior of the garbage can be fully burned. The oxygen-increas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com