Control method of incineration furnace for vessel

A control method and incinerator technology, applied in the field of control, can solve problems such as difficult control and unstable working process of marine incinerators, and achieve the effects of improving combustion conditions, reducing pollutant gas emissions, and simple control methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

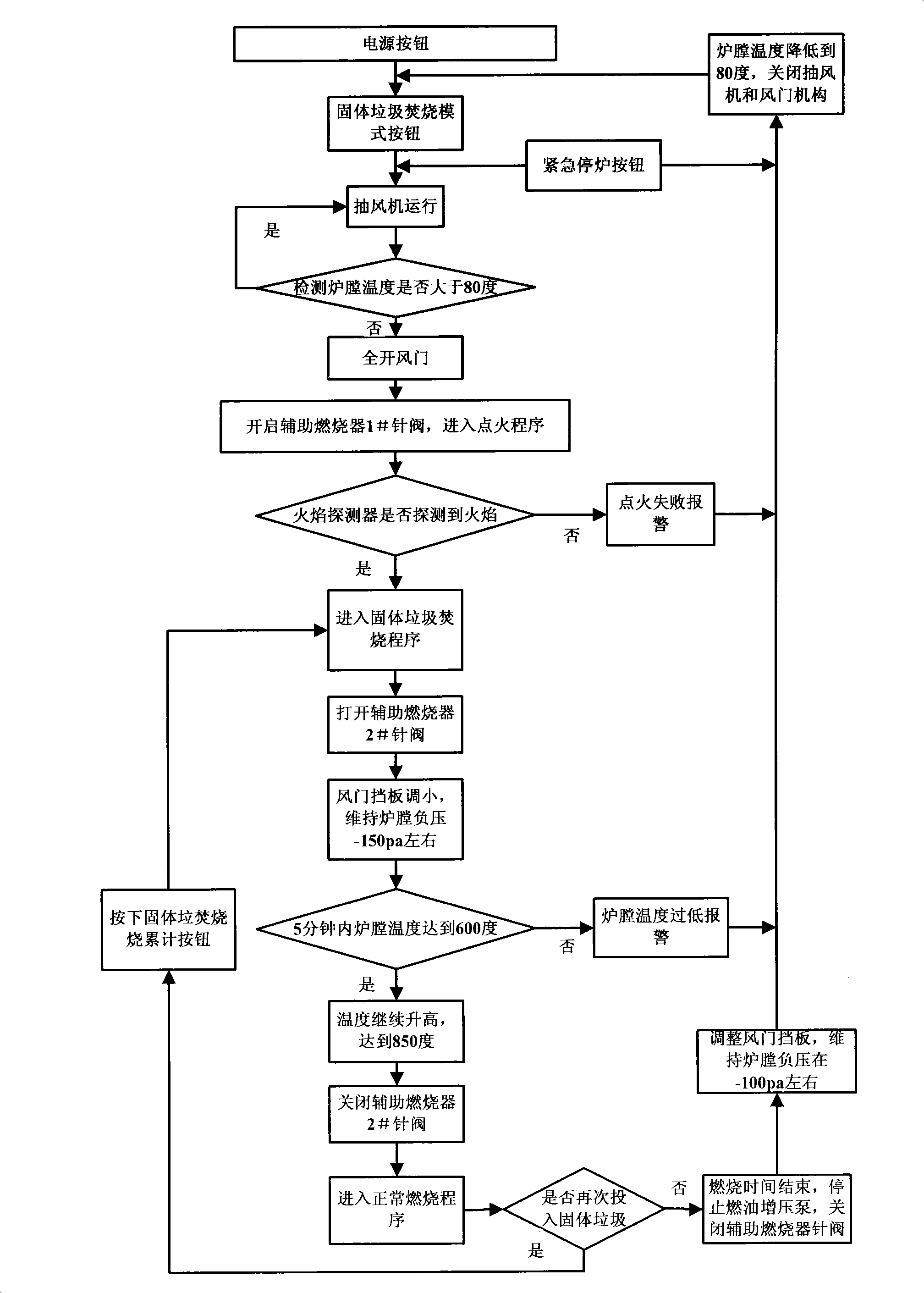

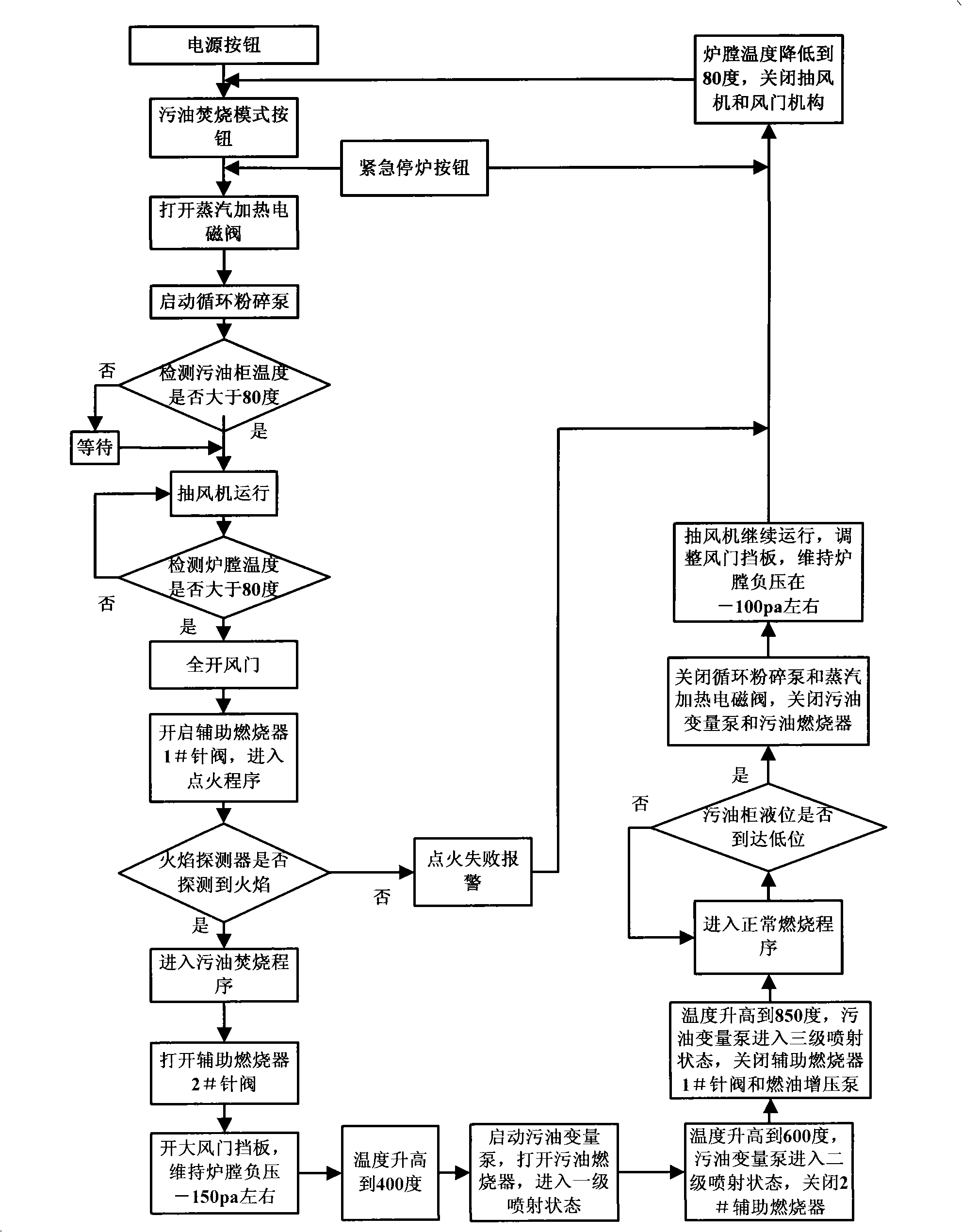

[0016] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

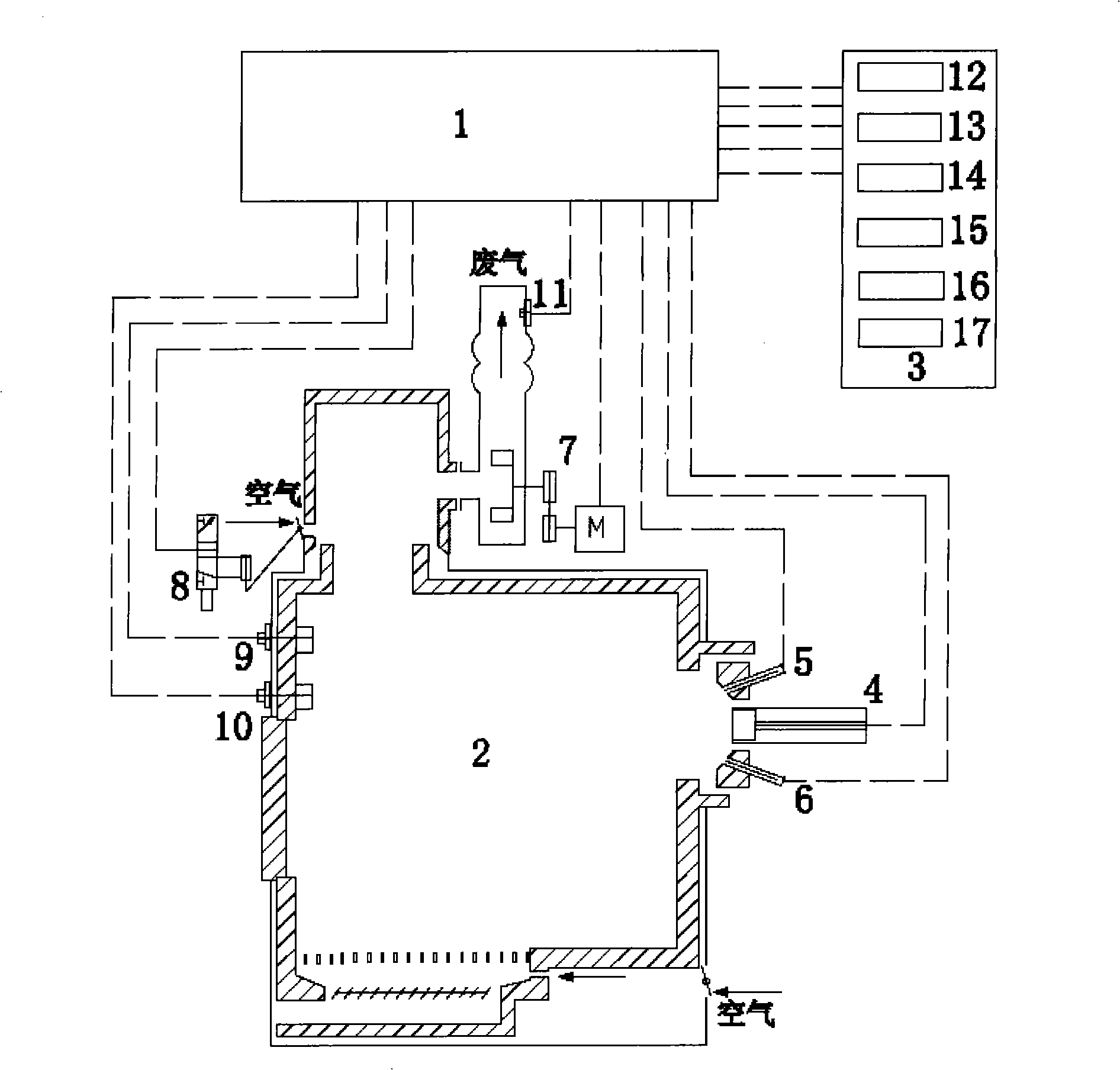

[0017] Such as figure 1 As shown, the control system adopted by the control method of the present invention includes a control unit 1, an incinerator body 2, an incinerator auxiliary control device 3, a dirty oil burner 4, an auxiliary burner 1# needle valve 5, an auxiliary burner 2# needle Valve 6, exhaust fan 7, damper baffle mechanism 8, incinerator furnace temperature sensor 9, incinerator furnace pressure sensor 10, incinerator chimney temperature sensor 11, wherein, incinerator auxiliary control equipment 3 includes fuel booster pump 12, sewage Oil variable pump 13, circulating crushing pump 14, steam heating solenoid valve 15, dirty oil tank temperature sensor 16, dirty oil tank liquid level sensor 17; control unit 1 uses a programmable logic controller (PLC) as a control component; dirty oil combustion 4, auxiliary burner 1# need...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com