Low nitrogen oxide incinerating device used for treatment of nitrogen containing waste gas and nitrogen containing waste liquid and low nitrogen oxide incinerating method used for treatment of nitrogen containing waste gas and nitrogen containing waste liquid

A low-nitrogen oxide, nitrogen-containing waste gas technology, applied in combustion methods, incinerators, combustion types, etc., can solve the problem of inability to reduce fuel-type nitrogen oxides, difficult to control the generation of nitrogen oxides, and lack of effective fuel-type nitrogen oxides. methods, etc., to achieve the effect of inhibiting generation and reducing conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

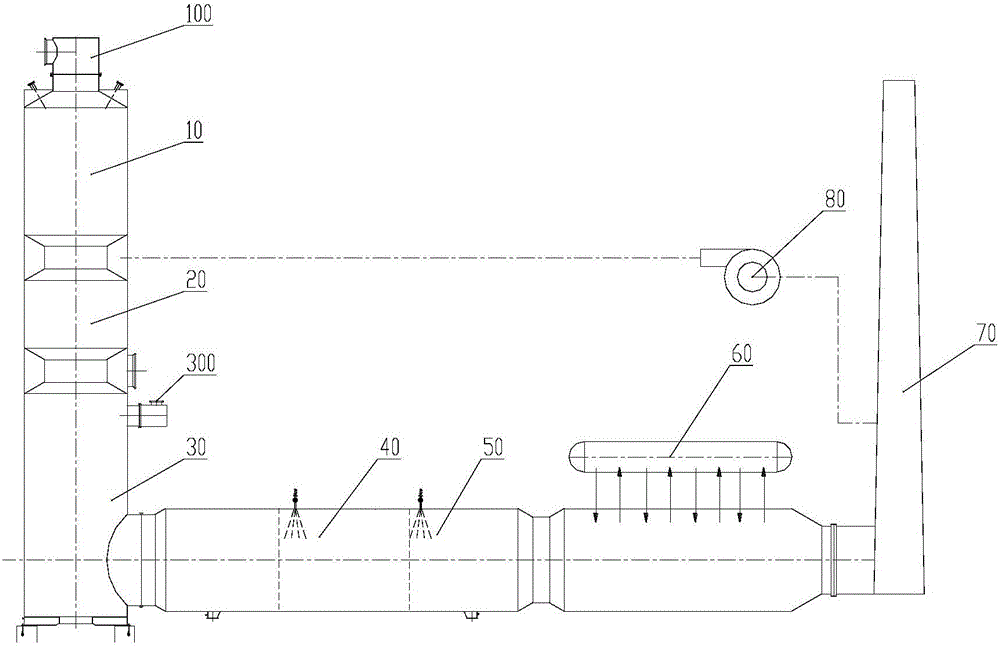

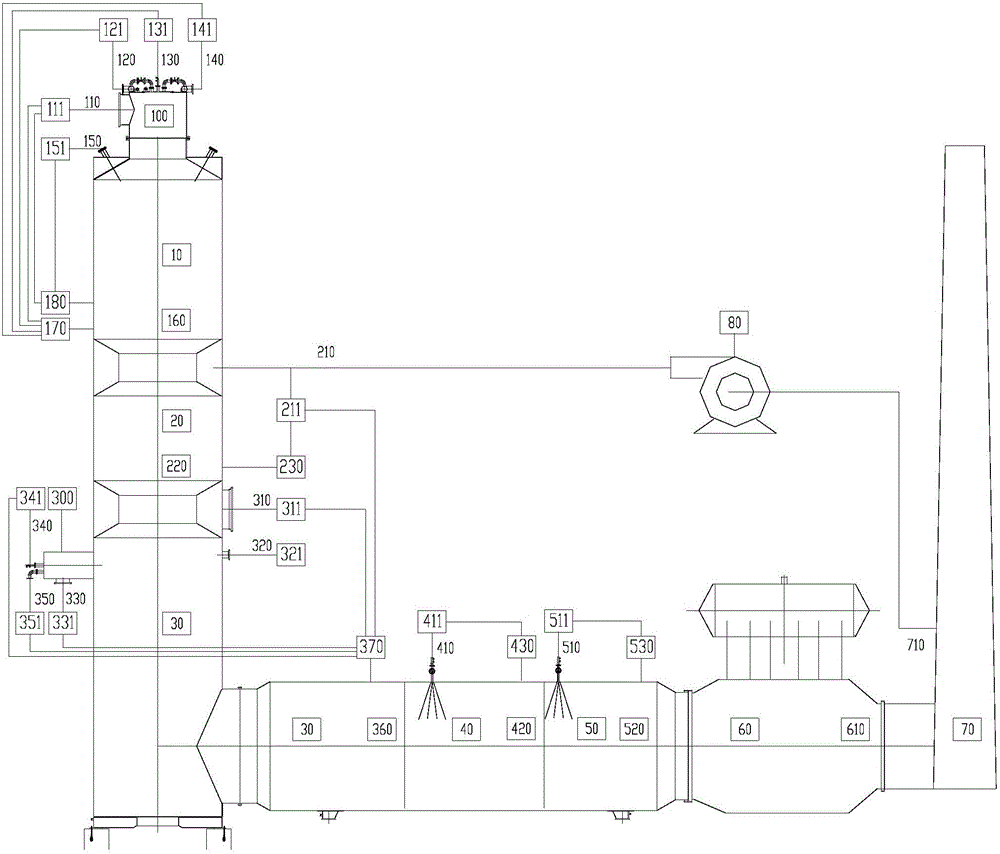

[0036] Such as figure 1 with image 3 As shown, a low-nitrogen oxide incineration device for treating nitrogen-containing waste gas and waste liquid according to the present invention includes an oxygen-deficient reduction section 10, and a primary product stream for processing the first product stream is arranged downstream of the oxygen-depleted reduction section 10 The quenching section 20, the oxidation section 30 for processing the second product flow is arranged downstream of the primary quenching section 20, the secondary quenching section 40 for processing the third product flow is arranged downstream of the oxidation section 30, and the secondary quenching section 40 is arranged downstream of the secondary quenching section 40 The SNCR denitrification section 50 for processing the fourth product stream is arranged downstream of the SNCR denitrification section 50 with a waste heat boiler 60 for recovering the enthalpy of the fifth product stream.

[0037] The oxygen ...

Embodiment 2

[0045] The difference from Example 1 is that the hypoxic reduction section 10, the primary quenching section 20, the oxidation section 30, the secondary quenching section 40, the SNCR denitrification section 50, and the waste heat boiler 60 are independent furnace bodies. connected in series.

Embodiment 3

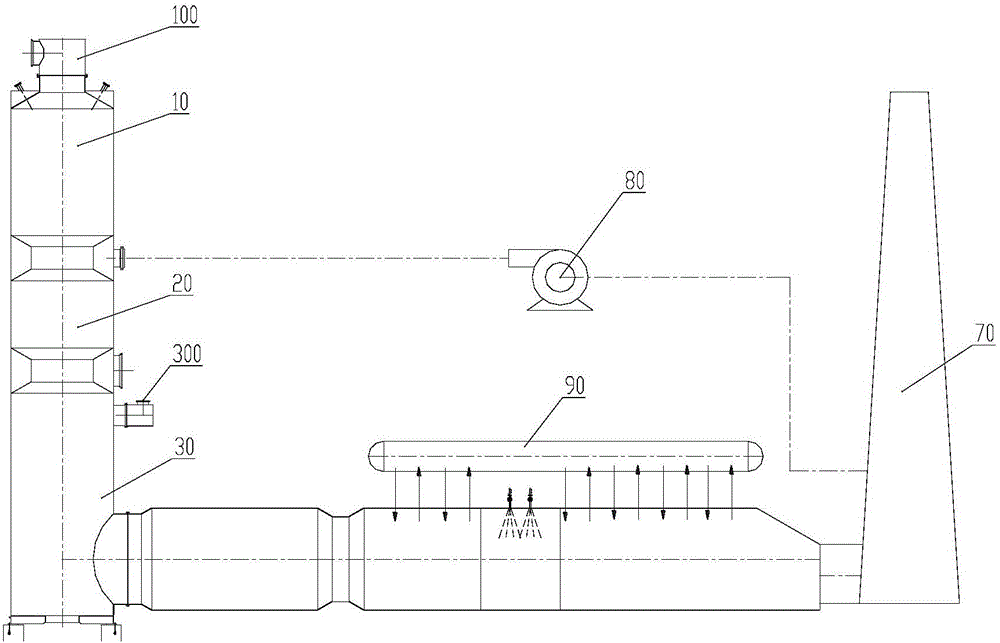

[0047] The difference from Example 1 is that, as figure 2 As shown, the secondary quenching section 40, the SNCR denitration section 50 and the waste heat boiler 60 of the incineration device are integrated into a boiler 90 with an SNCR denitration device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com