Control optimization method and device used for fire grate incinerator and based on flame radiation images

A technology of flame radiation and optimization device, applied in the field of waste incineration of grate incinerators, can solve the problems of hysteresis, uneven combustion, low combustion efficiency, etc., achieve real-time optimization of uniformity and efficiency, improve uniformity, and improve combustion The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

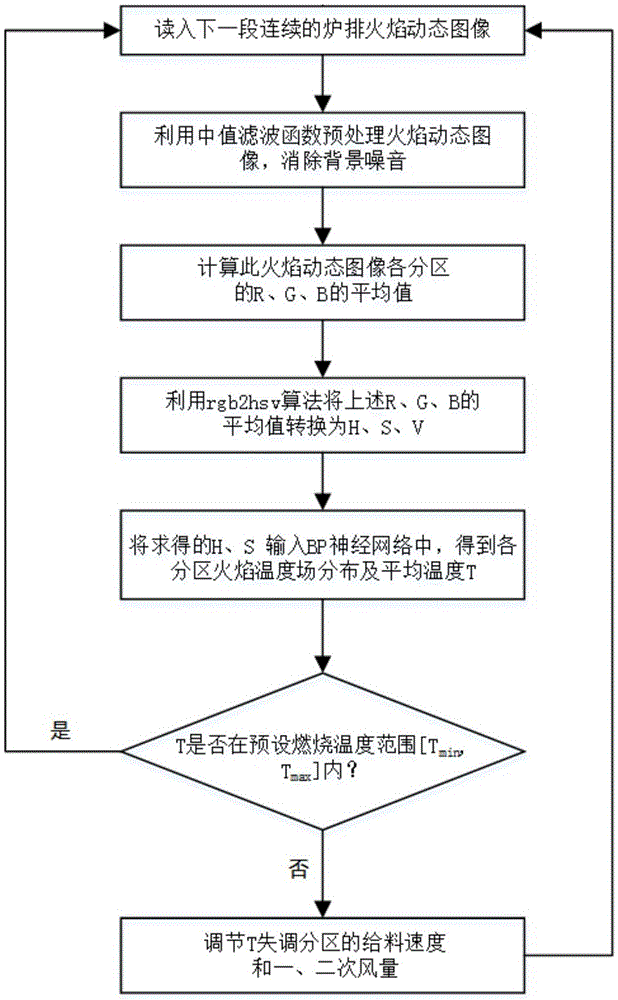

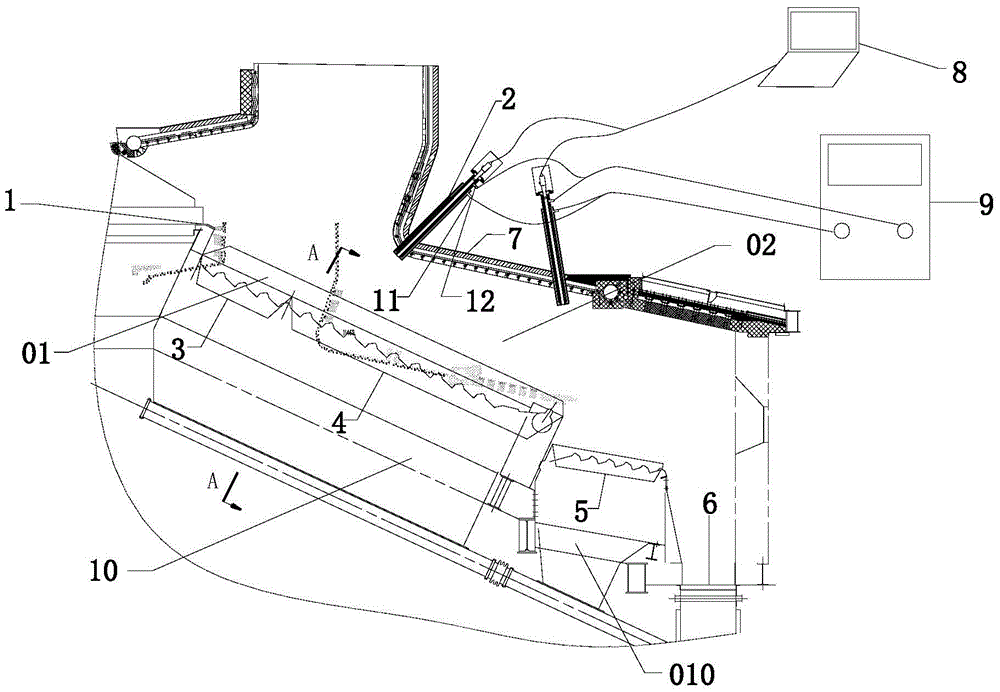

[0038] like figure 1 As shown, the control optimization method of the incinerator of the present embodiment comprises the following steps:

[0039] (1) The waste is put into the grate cavity from the feed port, burns in the waste combustion grate, passes through the drying area, combustion area and burnout area in turn, and is discharged from the slag outlet;

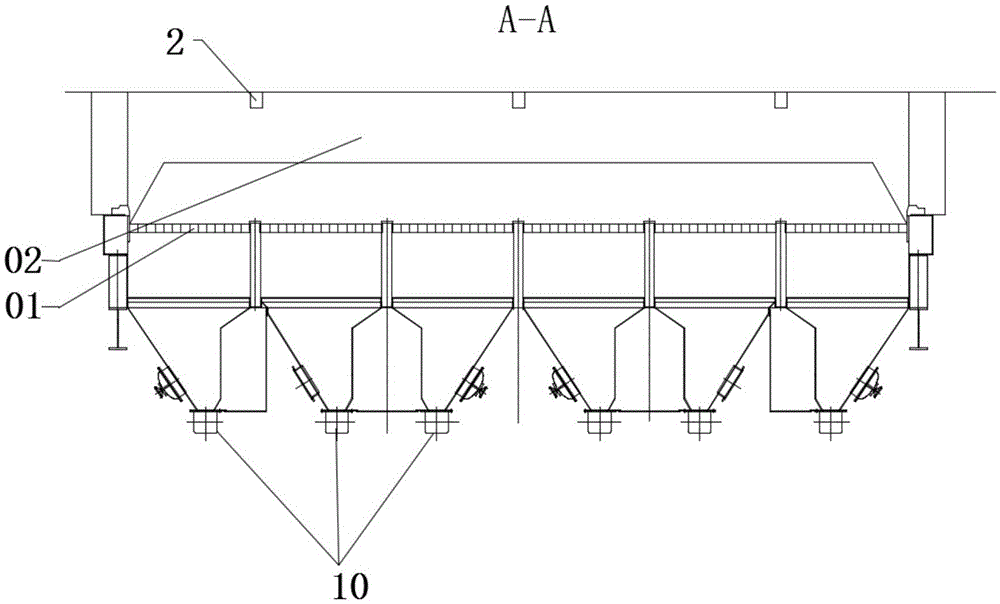

[0040] (2) Real-time shooting of the waste combustion situation in the combustion zone of each grate, and real-time photography of the waste combustion situation in the burnout zone of each grate, and using the median filter function to preprocess the obtained flame dynamic image to eliminate background noise; in the figure Each zone is the combustion zone and the burnout zone.

[0041] (3) within a unit time, obtain a plurality of flame images processed through step (2), and calculate the average value of R, G, and B of the flame images obtained;

[0042] (4) the average value of R, G, B of the flame image that step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com