Domestic organic waste splitting decomposition reductive transformation reaction processing process

A technology of organic waste and treatment process, which is applied in the fields of solid waste removal, petroleum industry, special form of dry distillation, etc. It can solve the problems of complex composition, pollution of air and groundwater sources, and increase of treatment cost, so as to achieve easy operation and guarantee The effect of continuous and efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

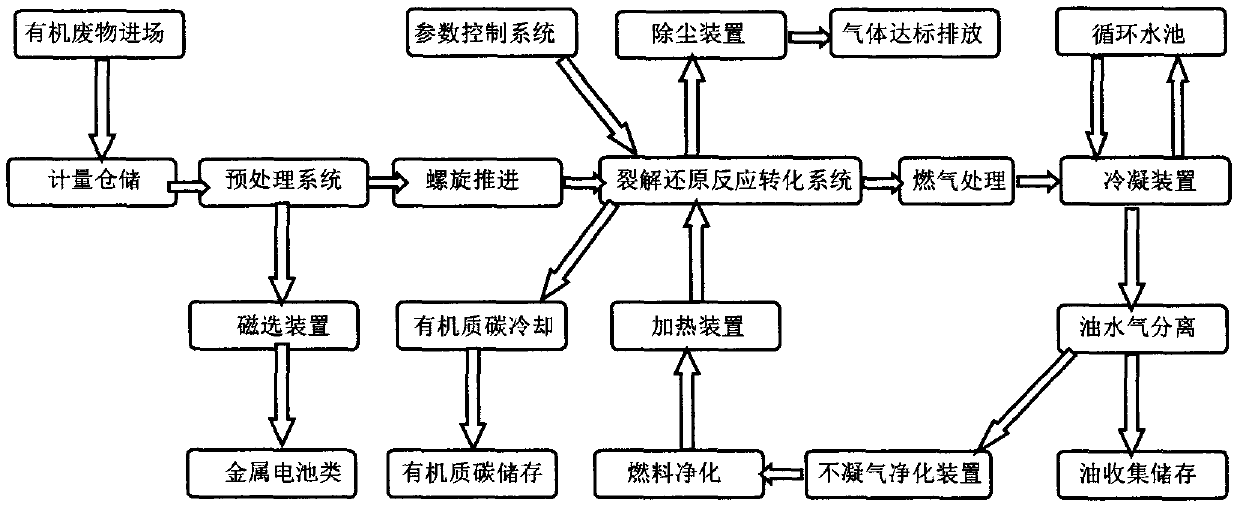

[0019] Such as figure 1 Shown:

[0020] a. Pretreatment system: remove the non-organic matter in the domestic organic waste, use the grab loader to feed the belt to the magnetic separator to remove metal and batteries, and send it to the crusher to crush it into 50-100 mm in size and less than 15 mm in thickness. In block shape, the pretreated domestic organic waste is transported to the feed bin of the pyrolysis reduction conversion reaction device through the belt conveyor, and then transported to the closed rotary cracking reduction conversion reaction device through the Archimedes screw propulsion device.

[0021] b. Cracking reduction conversion reaction system: The carbohydrates in domestic organic waste are composed of carbon, hydrogen and oxygen, which are transported to the closed rotary cracking reduction conversion reaction device through the Archimedes screw or hydraulic propulsion device. The rotary pyrolysis reduction conversion reaction device, through the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com