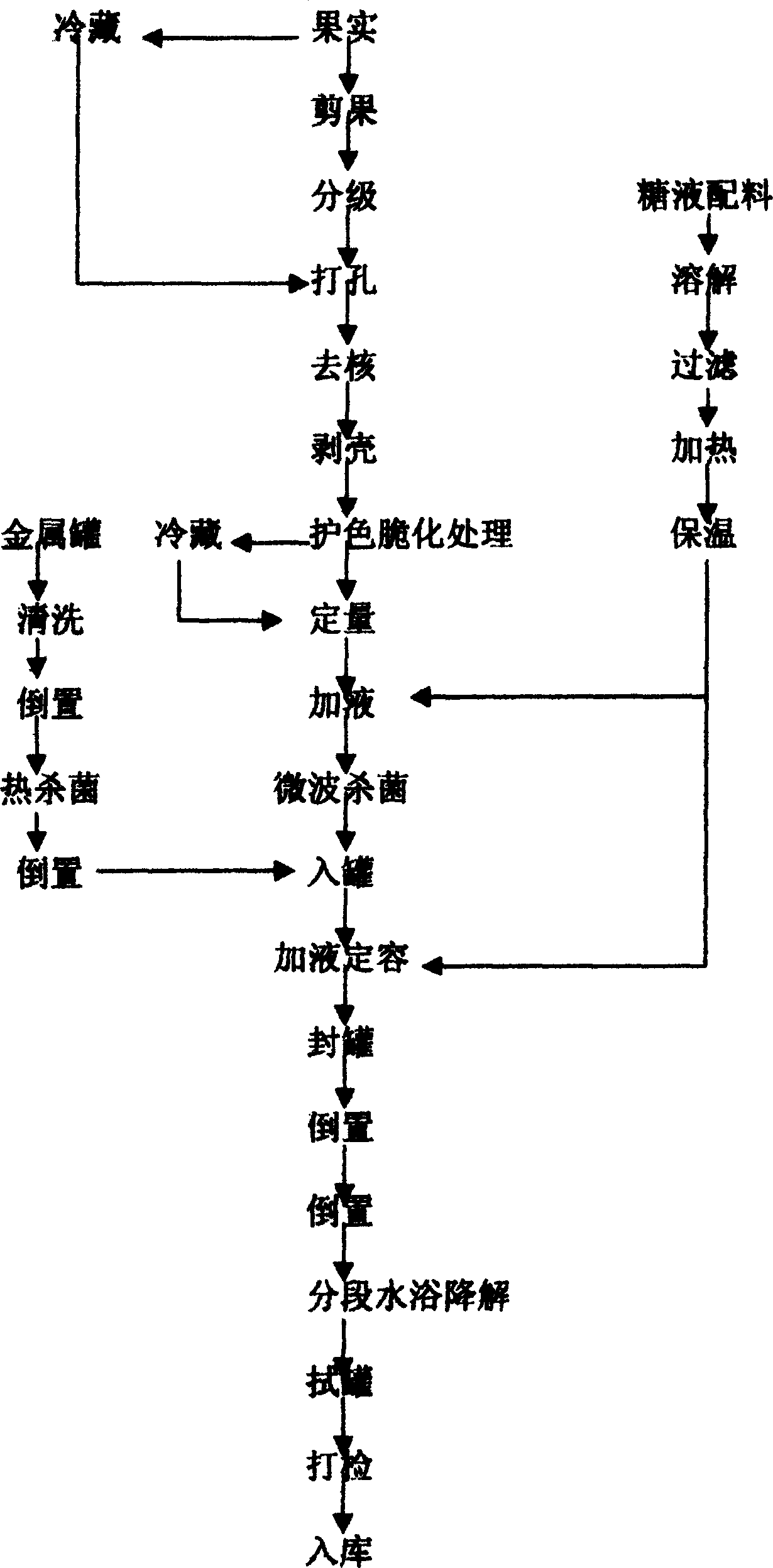

Tinned fruit production process

A production process and canned fruit technology, applied in the field of canned fruit production technology, can solve the problems of undiscovered patents and literature reports, reduce investment in fixed assets and equipment, solve the disconnection of mechanized production, and have the effect of strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below the present invention is further described in conjunction with embodiment:

[0028] This example introduces the production process of canned lychee in syrup (three-piece tinplate can).

[0029] 1. Cut the fruit Cut off the branched fruit from the fruit pedicle.

[0030] 2. Grading with a classifier (generally with a rotary stick classifier) to classify according to different fruit diameters.

[0031] 3. Punch out the core Use a puncher to punch a hole at the fruit pedicle, and then use the tweezers attached to the puncher to take out the core.

[0032] 4. Peel the peel off the fruit.

[0033] 5. Infusion Soak the pulp in the color-preserving crisp juice. The composition of the color-protecting crisp liquid is 0.075% sodium chloride, 1.1% calcium chloride or calcium lactate, 0.055% ascorbic acid or isovitamin C, and 0.25% citric acid , potassium alum (potassium aluminum sulfate) 0.075%, disodium edetate (EDTA) 0.018%, water 98.27%.

[0034] 6. Pulp microwave ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com