Composite inoculant for promoting decomposing of cellulose organic wastes, and preparation method thereof

A technology of organic waste and bacterial agent, applied in the biological field, can solve the problems of reduced decomposition ability of organic waste, high requirements for fermentation conditions, and unstable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1, preparation and detection of composite bacterial agent

[0048] 1. Bacteria culture on inclined plane

[0049] The preservation number of Sporotrichum thermophile is CICC2441, the preservation number of Trichoderma konigii is CGMCC3.4001, the preservation number of Phanerochaete chrysosporium is CGMCC5.776, and the preservation number of Aspergillus niger is CGMCC3. 03147, Saccharomyces cerevisiae (Saccharomyces cerevisiae) preservation number CICC1415, Bacillus subtilis (Bacillus subtilis) preservation number CICC10076, and Streptomyces ambofaciens (Streptomyces ambofaciens) preservation number ACCC40133. It was cultured statically for 48 hours at a temperature of 26°C.

[0050] 2. Expanded cultivation of liquid seeds

[0051] The strains cultured on the slant were picked and inoculated in the corresponding liquid medium (1L medium was inoculated with 4-6 needles), cultured on a shaking table at 28°C for 72 hours at a speed of 200rpm, and seven strains ...

Embodiment 2

[0061] Embodiment 2, preparation and detection of composite bacterial agent

[0062] 1. Bacteria culture on inclined plane

[0063] The preservation number of Sporotrichum thermophile is CICC2441, the preservation number of Trichoderma konigii is CGMCC3.4001, the preservation number of Phanerochaete chrysosporium is CGMCC5.776, and the preservation number of Aspergillus niger is CGMCC3. 03147, Saccharomyces cerevisiae (Saccharomyces cerevisiae) preservation number CICC1415, Bacillus subtilis (Bacillus subtilis) preservation number CICC10076, and Streptomyces ambofaciens (Streptomyces ambofaciens) preservation number ACCC40133, these 7 strains were inoculated on the corresponding slant culture medium respectively. The cells were cultured statically for 24 hours at a temperature of 30°C.

[0064] 2. Expanded cultivation of liquid seeds

[0065] Pick the strains cultured on the slant and inoculate them respectively (4-6 needles in 1L culture medium) in the corresponding liquid ...

Embodiment 3

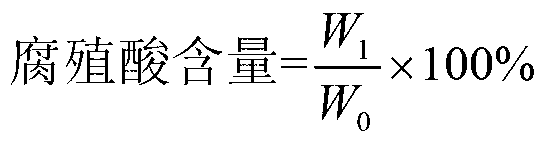

[0075] Embodiment 3, compound bacterial agent application

[0076] The compost with cassava residue as the main raw material is as follows:

[0077] Compost raw material composition: cassava alcohol residue (particle size less than 2mm, C / N about 45) 75% (mass percentage content) and filter mud (cassava alcohol plant waste water filter mud) 25% (mass percentage content);

[0078] Production process: Add the composite bacterial agent obtained in Example 1 or Example 2 respectively according to 0.2% and 0.22% of the composting raw material quality, adjust the C / N to 30 with urea, and adjust the water content to 60% (mass percentage content) , fully stirred evenly, and piled into strips with a height of no more than 80cm and a width of 150-200cm at the bottom. Manual turning is adopted, and the compost is turned once every 3 days during the high temperature period, and once every 5 days during the cooling period, to obtain fertilizer. The same compost raw material without compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com