Bioorganic fertilizer using agricultural waste as raw materials and preparation method of bioorganic fertilizer

A bio-organic fertilizer and agricultural waste technology, applied in the field of bio-organic fertilizer and its preparation, can solve the problems of complex microorganisms, narrow application range, and inconvenient implementation, and achieve the effects of simple cultivation, easy operation, and shortened composting cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The bio-organic fertilizer with the following components in parts by weight:

[0020] Livestock and poultry manure 40, biogas residue 20, biogas slurry 20, mushroom residue 5, meal 5, oil foot 3, fermentation inoculum 1. The fermentation bacterial agent is a composite preparation of white rot fungus and Bacillus subtilis. The livestock manure is a mixture of chicken, cow, sheep and pig manure. Said meal is cotton meal, and said oil foot is leftovers of food oil processing.

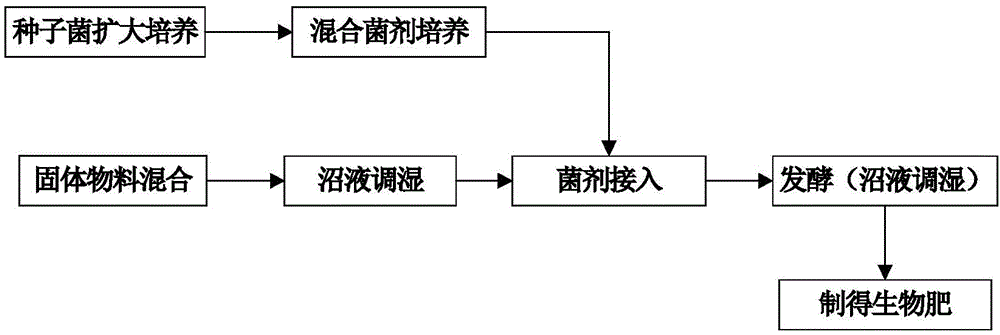

[0021] like figure 1 , the preparation steps of this organic fertilizer are:

[0022] The first step is the preparation of bacterial agents.

[0023] The strains used in the present invention all come from the China Industrial Microorganism Culture Collection and Management Center, and the white rot bacteria are Phanerochaete chrysosporium (Phanerochaete chrysosporium), accession number 40299, Bacillus subtilis ( Bacillus subtilis ), deposit number 10035.

[0024] The purified and cultured ...

Embodiment 2

[0033]The difference between Example 2 and Example 1 is that the proportion of material components is different, specifically: 50 of livestock and poultry manure, 15 of biogas residue, 20 of biogas slurry, 10 of mushroom residue, 10 of meal, 5 of oil feet, and 2 of fermentation inoculum. The fermentation bacterial agent is a composite preparation of white rot fungus and Bacillus subtilis. The livestock manure is a mixture of chicken, cow, sheep and pig manure. The meal is a mixture of cotton meal and soybean meal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com