Vegetable waste organic fertilizer and preparation method thereof

A technology of vegetable waste and production method, which is applied in the field of organic fertilizer and planting waste treatment and disposal, can solve problems such as vegetable waste polluting the environment, and achieve the effects of reducing nutrient loss, improving microbial activity, and being easy to implement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Organic fertilizer composition by weight: organic material (the present embodiment is sawdust) 15%, calcium cyanamide 3% (in the present embodiment, by weight percentage, nitrogen-containing 20%, containing calcium oxide 45%, all the other are Impurities, pH 11.0~12.5), natural zeolite 4%, vegetable waste (by dry weight) 78% (this embodiment is the remaining root and leaf waste in the process of making Chinese cabbage to clean vegetables).

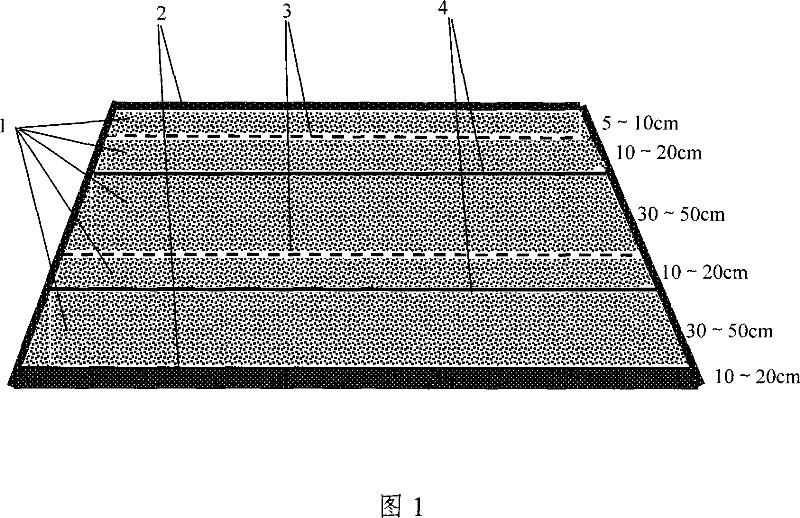

[0028] Choose a relatively flat bare ground as a vegetable waste dump, spread a layer of 15cm thick organic materials, and spread a 40cm thick vegetable waste on the organic materials, and evenly sprinkle calcium cyanamide total amount according to the weight percentage. 50% of the weight, then spread 15cm thick vegetable waste, evenly sprinkle 50% of the total weight of natural zeolite powder by weight percentage, then spread 40cm thick vegetable waste, and evenly sprinkle calcium cyanamide by weight percentage 50% of the total wei...

Embodiment 2~12

[0030] The difference from Example 1 is that the proportioning of raw materials and the height of material stacking are different (Table 1), and the preparation method is the same as in Example 1.

[0031] Table 1

[0032] make up

[0033] In the above table, materials refer to organic materials, vegetable waste refers to the residues in the vegetable production and sales process, calcium cyanide refers to calcium cyanamide, and zeolite refers to natural zeolite powder. Vegetable waste in Examples 2-12 adopts vegetable production base greenhouse or field to produce leafy vegetables (cabbage, scallion, lettuce, rape, celery, potherb mustard, coriander, Chrysanthemum chrysanthemum, spinach, amaranth, etc.), solanaceous fruits (tomato, Eggplant, pepper, etc.), melons (cucumber, pumpkin, wax gourd, zucchini, loofah, bitter gourd, etc.) or legumes (kidney beans, lentils, cowpea, broad beans, etc.) If the vegetable waste is vegetable seedlings, vines, vines, roots, or ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com