Degraded starch foaming machine

A technology for degrading starch and foaming machines, applied in the field of foaming machines, to achieve the effects of improving the rate of high-quality products, reasonable structure, and reducing material clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further explained below in conjunction with the accompanying drawings of the specification.

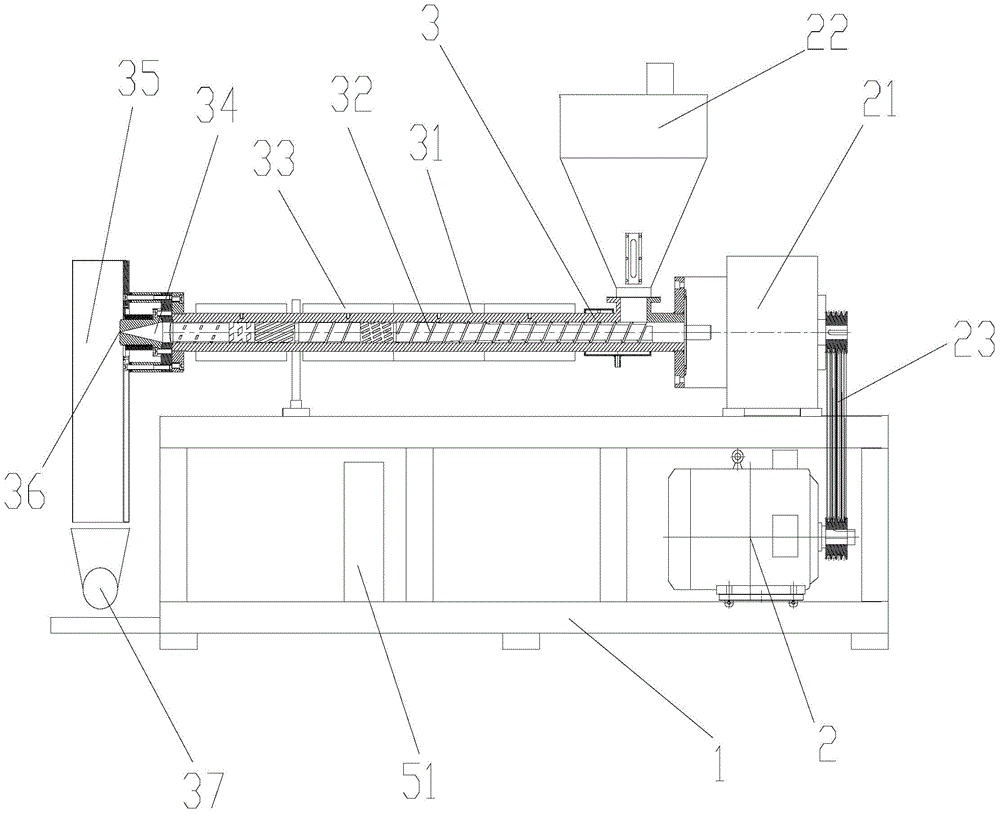

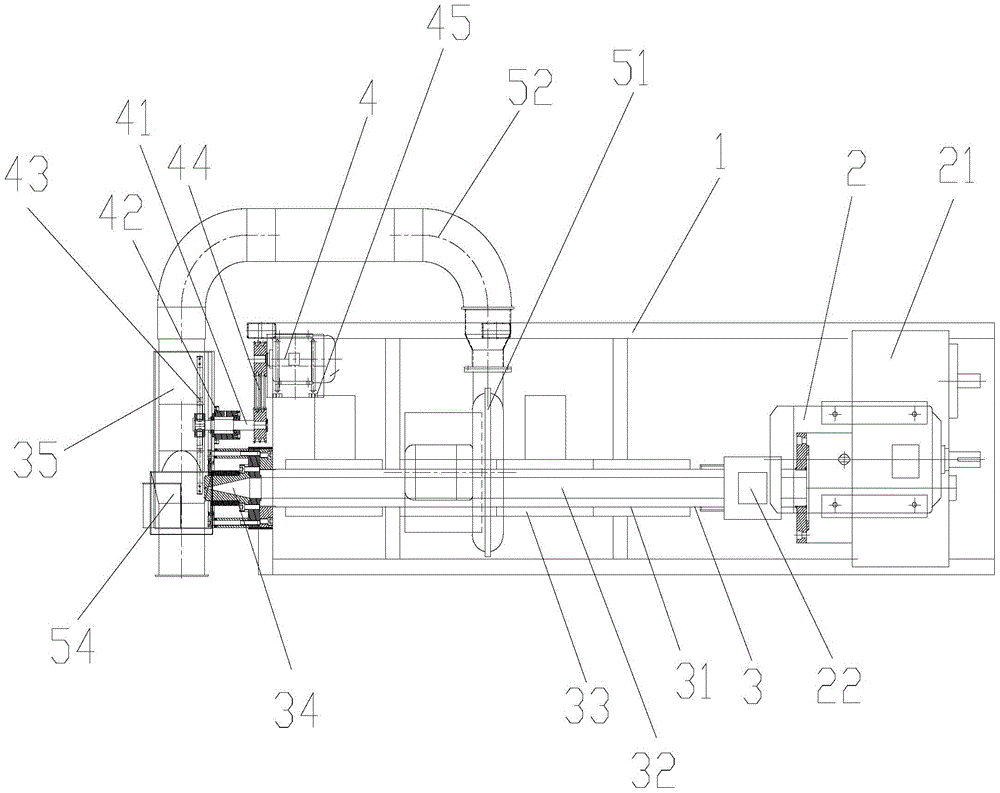

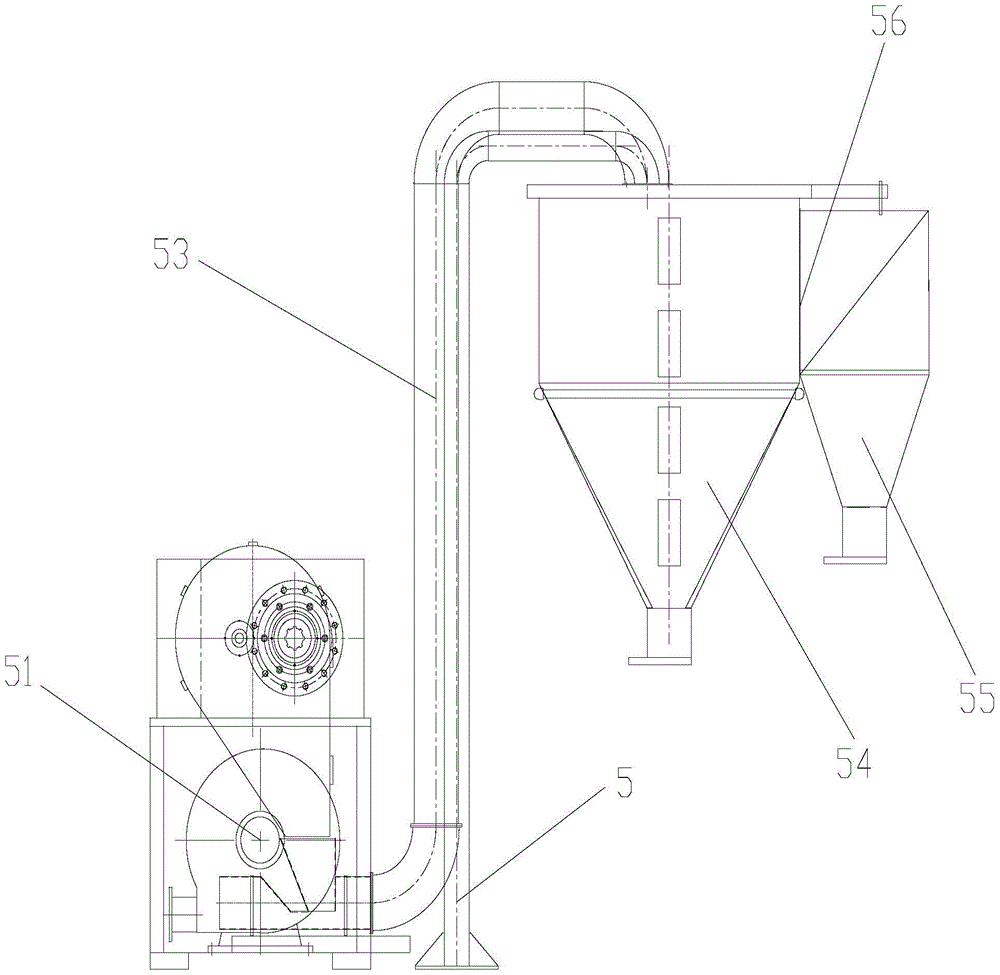

[0037] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a degradable starch foaming machine includes a frame 1, an extrusion device, a pelletizer, and a receiving device; the extrusion device and the pelletizer are arranged on the frame 1, and the receiving device is arranged On the side of rack 1.

[0038] The extrusion device includes an extrusion device motor 2, a reduction box 21, a feed barrel 22, and an extruder 3. The extrusion device motor 2 and the reduction box 21 are connected by a belt 23, the reduction box 21 and The extruder 3 is connected, the feed barrel 22 is arranged between the reduction box 21 and the extruder 3; the reduction box 21 is arranged at the upper end of the frame 1, and the extruder motor 2 is arranged vertically on the reduction box 21 On the bottom of the frame 1 beam.

[0039] The extruder 3 includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com