Seedling substrate using coffee processing residues as raw material and preparation method thereof

A technology for processing residues and seedling substrates, which is applied in the field of substrate preparation, can solve the problems of insufficient nutrients, inconvenient transportation, large volume, etc., and achieve the effects of reducing the cost of seedling cultivation, reducing the weight of containers, and improving the air permeability of the substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

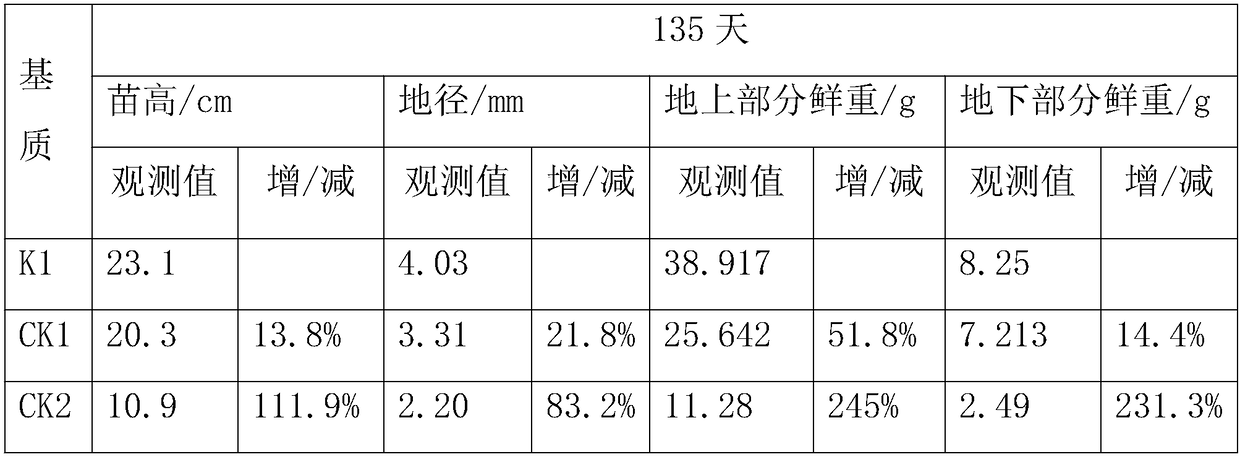

Embodiment 1

[0014] The seedling raising matrix raw material formula is (volume percentage): 32% coffee processing residue, 8% cow dung, 30% expanded perlite, 30% vermiculite.

[0015] Preparation:

[0016] Collection and pretreatment of matrix raw materials: Stack coffee processing residues in the open air, remove non-biodegradable substances that are difficult to ferment in the raw materials, and obtain coffee processing residues with a particle size of 1.3-7.6mm for use;

[0017] Fermentation: Mix the product obtained in the above steps with the cow dung according to the above volume percentage, every 3m 3 Add 1kg of antiseptic (V-100 bacterial agent) to the material and mix it evenly and cover it with straw. The initial carbon-nitrogen ratio of the above mixture is 20:1-35:1, the moisture content is 50-60%, and the maximum composting temperature 60-65°C, turn the compost once every 4 days, ferment at a temperature of around 60°C for 90 days, until the color of the compost heap turns d...

Embodiment 2

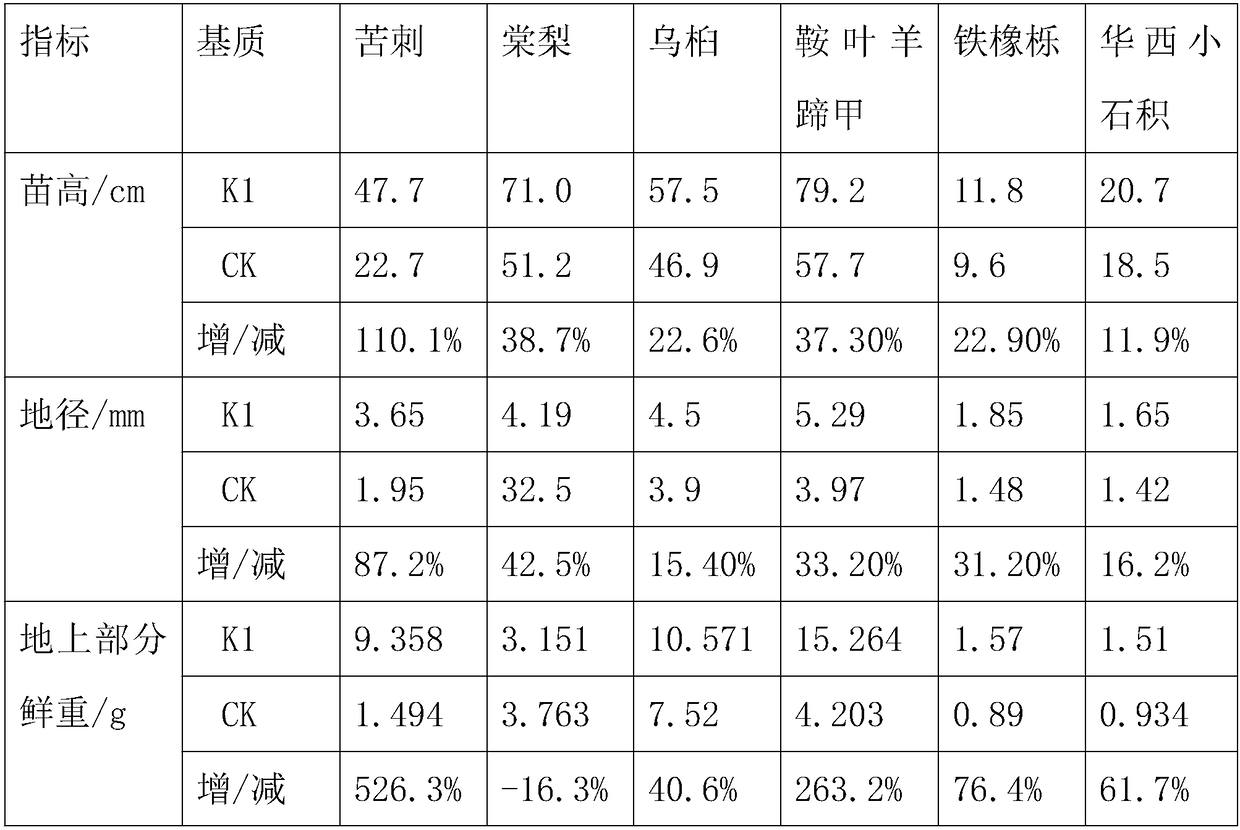

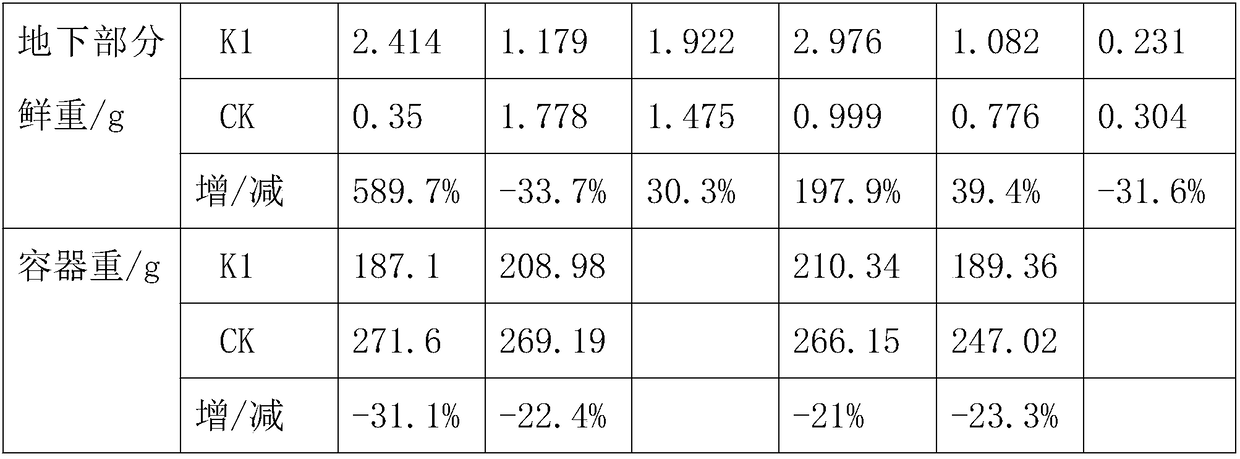

[0026] The seedling-raising matrix that embodiment 1 is made is packed in 9cm * 13cm non-woven fabric container, is placed on the seedbed of wide 1.2m neatly, then the processed bitter thorn, Tang pear, Chinese tallow tree, saddle-leaf sheep hoof beetle, iron The seeds of 6 tree species of Oak Oak and Huaxi Xiaoshiji are directly sown on demand in a non-woven container and carried out 6 months of bag seedling cultivation, and the seedling growth and biomass of each tree species are measured, and the results are shown in Table 2 (K1 refers to embodiment 2 gained matrix).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com