Modular system for wet coffee processing without water pollution

A coffee bean, modular technology, used in green coffee processing, application, removal of impurities, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

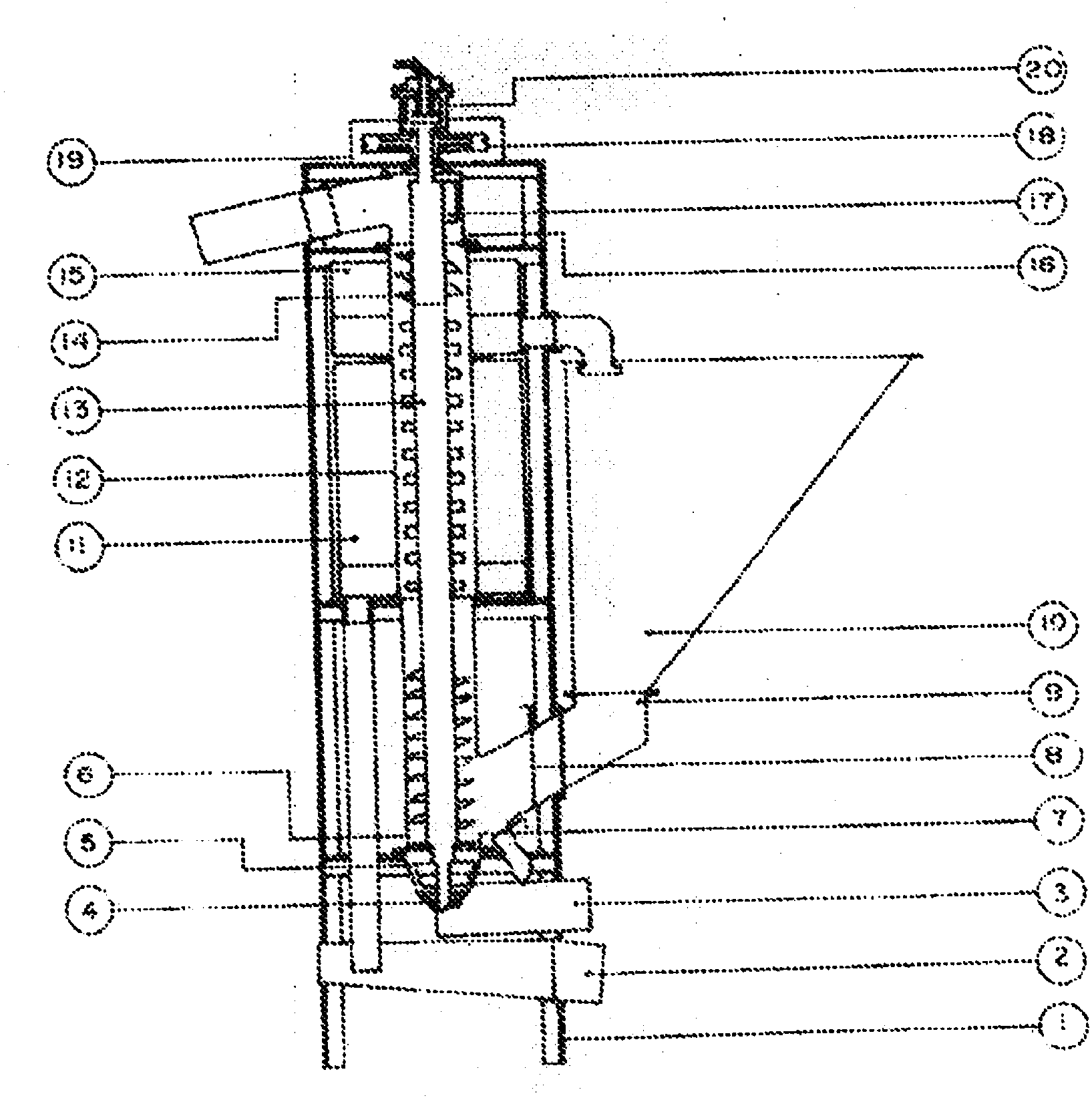

[0028] refer to image 3 , 4, 5, 6 and 7, describe the preferred embodiment of the present invention in detail:

[0029] Coffee Bean Cleaning Machine(17)

[0030] Coffee bean cleaning devices can be manufactured to process washed coffee beans in quantities between 500 kg / h and 5000 kg / h. The components in each module for processing different amounts of coffee beans are the same, in terms of cleaning machine (17) size and number of agitators (2), drive propeller (7) and intermediate propeller (6), rotor size (1) changes, as shown in Table 1. The rest of the components in each module - such as the tank, the worm wheel that feeds the coffee beans to the cleaning agent at the required flow rate according to the model, the number of depulpers and their capacity - have different dimensions according to the capacity of each.

[0031] Table 1 Rotor specifications of coffee bean cleaning devices with different capacities (kilograms of coffee beans washed per hour)

[0032]

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com