Myceliated coffee products and methods for making

A mycelium, coffee technology, applied in food preparation, coffee, green coffee processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

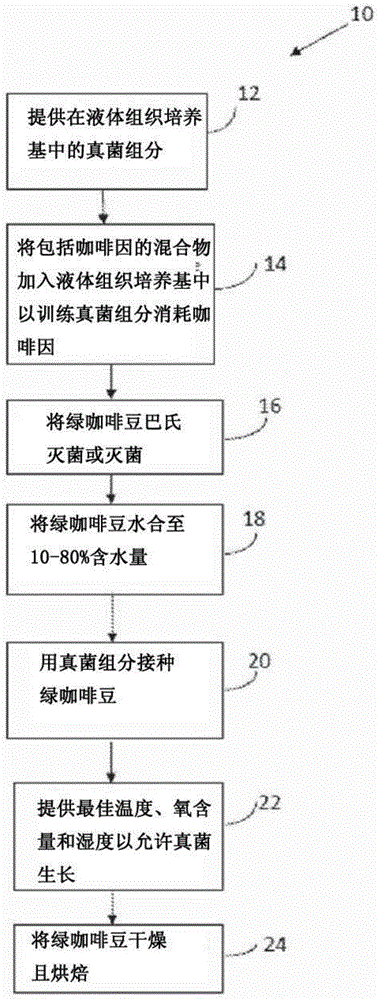

[0099] Preparation of fungal fractions for inoculation of green coffee beans

[0100] In one embodiment, the method for preparing a fungal component to inoculate prepared green coffee beans comprises scaling up a fungal component as defined herein in liquid culture. Such fungal components ready for inoculation of prepared coffee beans are referred to as "prepared fungal components".

[0101] In one embodiment, the prepared fungal component is in solid culture. In another embodiment, the fungal component is prepared in liquid culture. In another embodiment, the fungal component is prepared as a mixture of solid and liquid cultures. Liquid culture can be accomplished by any method known in the art, and includes the use of bioreactors. For example, when a bioreactor is used to prepare the fungal fraction, the bioreactor can be prepared by diluting the undefined medium containing the green coffee bean extract broth up to 100Ox with filtered / RO water. In one embodiment, the jac...

Embodiment approach

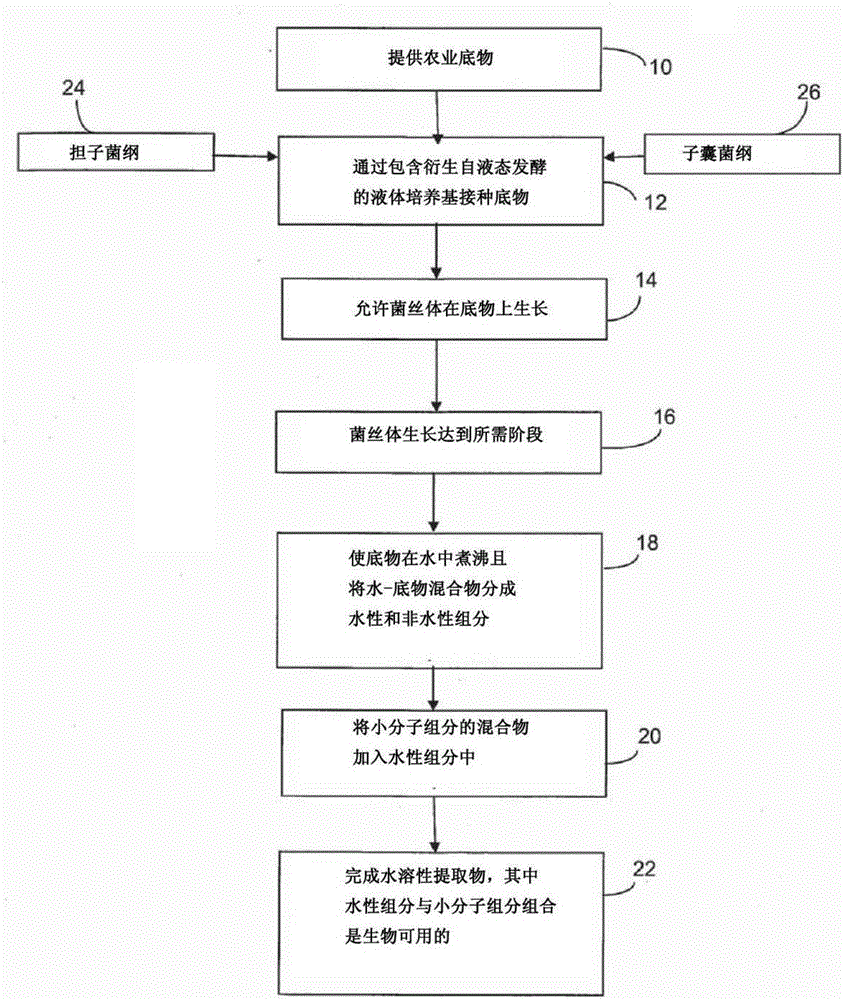

[0149] figure 1 A flow diagram of one embodiment of a method of preparing an extract of a myceliumized agricultural product (eg, a myceliumized coffee product) for human consumption is shown. Step 10 provides an agricultural substrate, step 12 inoculates the substrate with a liquid medium comprising an aliquot of culture derived from liquid fermentation, step 14 allows mycelium to grow, and step 16 inoculates the mycelium on the substrate Growth, step 18 comprising after mycelial growth on the substrate reaches the desired stage, boiling the substrate in water and separating the water-substrate mixture into aqueous and non-aqueous components, step 20 separating the mixture of small molecule components Added to the aqueous component whereby the aqueous component mixes in a bioavailable combination with small molecule components that promote the water solubility of the extract.

[0150] In one embodiment, step 24 is performed for step 12 using a culture of Basidiomycota fungi....

Embodiment 1

[0179] Specific and pure strains of the fungus from the mentioned collections are handled in a sterile environment in 1 gallon to 10 gallon plastic bags, 1 quart to 1 gallon glass jars, or on 10cm to 15cm culture plates , using a non-defining organic fruit and plant based medium comprising green coffee bean extract with 1.5% agar (w / v) in order to monitor and ensure the general vigor and health of the strain.

[0180] Mycelium samples were grown for 2 to 4 weeks in a mild ambient sterile air flow, then excised from the culture plates, and subsequently used to inoculate into liquid fermentations using similar non-defining organic fruit and plant based media ( but without agar), using ambient air, in 1 quart to 1 gallon glass jars. Some samples were grown in agitated cultures and some samples were grown in unagitated cultures in stainless steel tanks designed for commercial beer brewing and / or fermentation in ambient air.

[0181] Unagitated liquid fermentation formed floating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com