Coffee brewing equipment capable of automatically adjusting temperature

An automatic adjustment and brewing technology, which is applied in beverage preparation devices, home appliances, applications, etc., can solve the problems that coffee cannot satisfy different people's preferences, the brewing process is single, and the space for intervention is small, so as to improve the quality of coffee brewing , Improve uniformity, improve the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

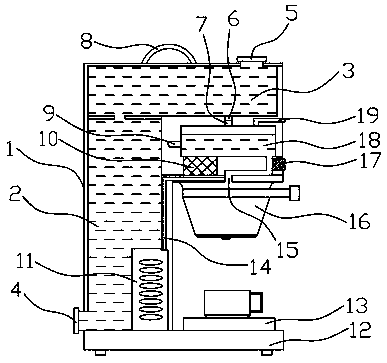

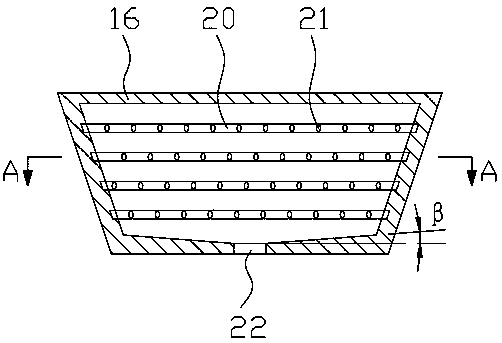

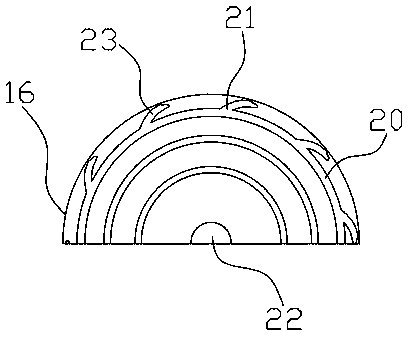

[0020] Such as Figure 1~4 As shown, the coffee brewing device that can automatically adjust the temperature includes a housing 1, a base 12 connected to the bottom of the housing 1, and a brewing box 16 arranged in cooperation with the housing 1. The bottom of the brewing box 16 is provided with a brewing The outlet 22, the inner wall of the brewing box 16 is provided with at least one concave ring 20, the inner wall of the concave ring 20 is evenly distributed with air outlet holes 21, the air outlet holes 21 are correspondingly connected to the steam branch pipe 23, and the steam branch pipe 23 is connected to the housing 1 through the steam pipe 14 Boiler 11 at the lower end. When coffee brewing is required, open the steamer 11 to make it work and continuously output hot steam. The hot steam enters the steam pipe 23 from the steam pipe 14, and the steam with a certain pressure is pressed into the brewing box 16 from the steam pipe 23 through the air outlet 21. Inside, the...

Embodiment 2

[0028] This embodiment is a further optimization scheme on the basis of Example 1: the steam conduit 14 adopts high-temperature-resistant rubber material, and the preferred preparation method of the rubber material is: take by weight, 56 parts of chlorohydrin rubber, 13 parts of quick-pressed charcoal Black, 7 parts of titanium dioxide, 11 parts of antimony trioxide, 8 parts of decabromodiphenylethane, 6 parts of calcium hydroxide, 0.8 parts of stearic acid, 9 parts of talc, 12 parts of silicon dioxide, 8 parts of magnesium oxide , 0.6 parts of accelerator and 1.1 parts of aging inhibitor are put into the internal mixer, and the rubber with a hardness of 85Hs, a tensile strength of 13MPa and an elongation of 190% is synthesized by the internal mixer, and is filtered; the obtained rubber is put into Extrusion molding in the open mill; put the molded rubber into the vulcanization equipment, under the pressure of 250Kgf / cm 2 , at a temperature of 151° C., vulcanization treatment ...

Embodiment 3

[0031] Such as Figure 1~4 As shown, the working principle of the present invention is: when coffee brewing is required, unscrew the brewing box 16 that is threadedly connected to the housing 1 and put in an appropriate amount of coffee powder, screw on the brewing box 16 again and set the required brewing temperature, the equipment starts to work, the water filling valve 7 is opened, and the water inside the upper water chamber 3 enters the heating chamber 18 from the water inlet 6. When the water inside the heating chamber 18 reaches 85% of the inner space of the heating chamber 18, add water The valve 7 is closed, and the heating device 10 starts to heat the water body inside the heating chamber 18. During the heating process, the air inlet pipe 9 continuously introduces gas into the heating chamber 18, and the temperature is adjusted to the set temperature under the joint action of the heating device 10 and the air inlet pipe 9. After the heating is completed, the hot wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com