High-efficiency anaerobic fermentation equipment

An anaerobic fermentation and equipment technology, applied in the field of beer brewing, can solve the problems of affecting the hygienic quality and flavor of beer, unable to completely kill germs, and high equipment cost, achieve fast but efficient cleaning, avoid hygienic quality and flavor, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

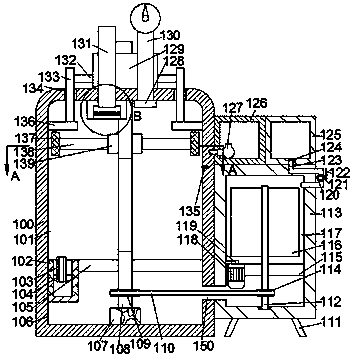

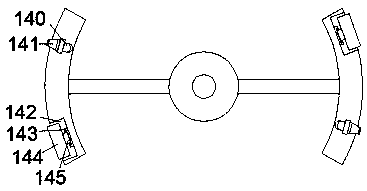

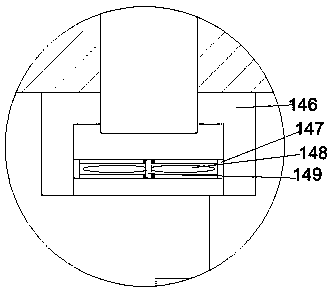

[0017] like Figure 1 to Figure 3 As shown, the present invention is described in detail. For the convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship are consistent. A high-efficiency anaerobic fermentation equipment of the present invention includes a fermentation tank 100, and a fixed block 129 is fixedly connected to the outer wall of the top end of the fermentation tank 100. The fixed block 129 is provided with row Gas mechanism and pressure measurement mechanism, wherein said exhaust mechanism is used to discharge the gas in 101, and said pressure measurement mechanism is used to visually reflect the air pressure situation in 101, and said fermentation box 100 is fixedly connected with partition plate 105, The partition plate 105 divides the chamber in the fermentation tank 100 into a fermentation chamber 101 and a motorized chamber 106, whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com