A kind of mixing process of fermented grains

A wine grain and process technology, applied in the field of wine grain mixing technology, can solve the problems of insufficiently uniform mixing, occupation of manpower, low mixing efficiency, etc., and achieve the effects of sufficient mixing and improving brewing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

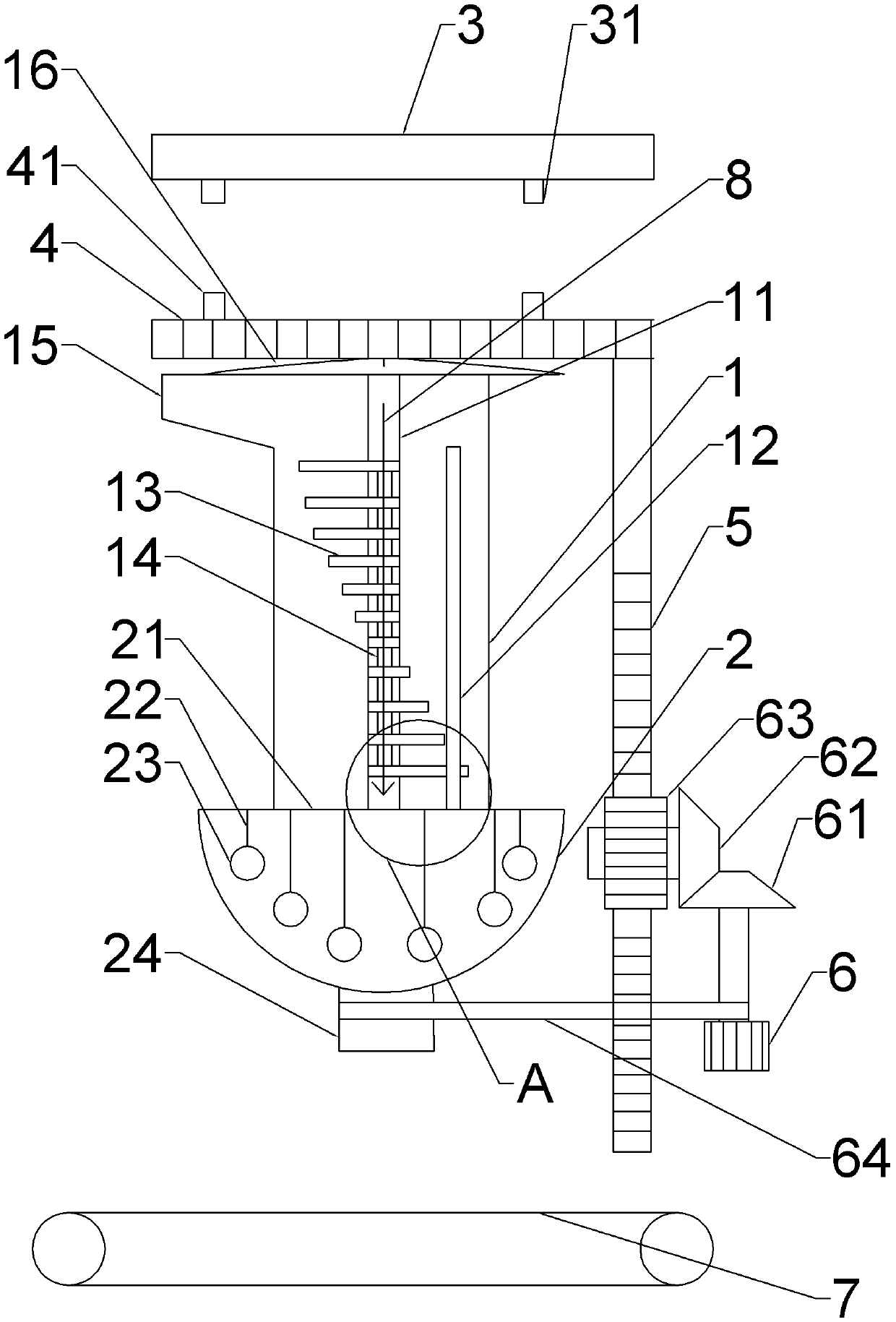

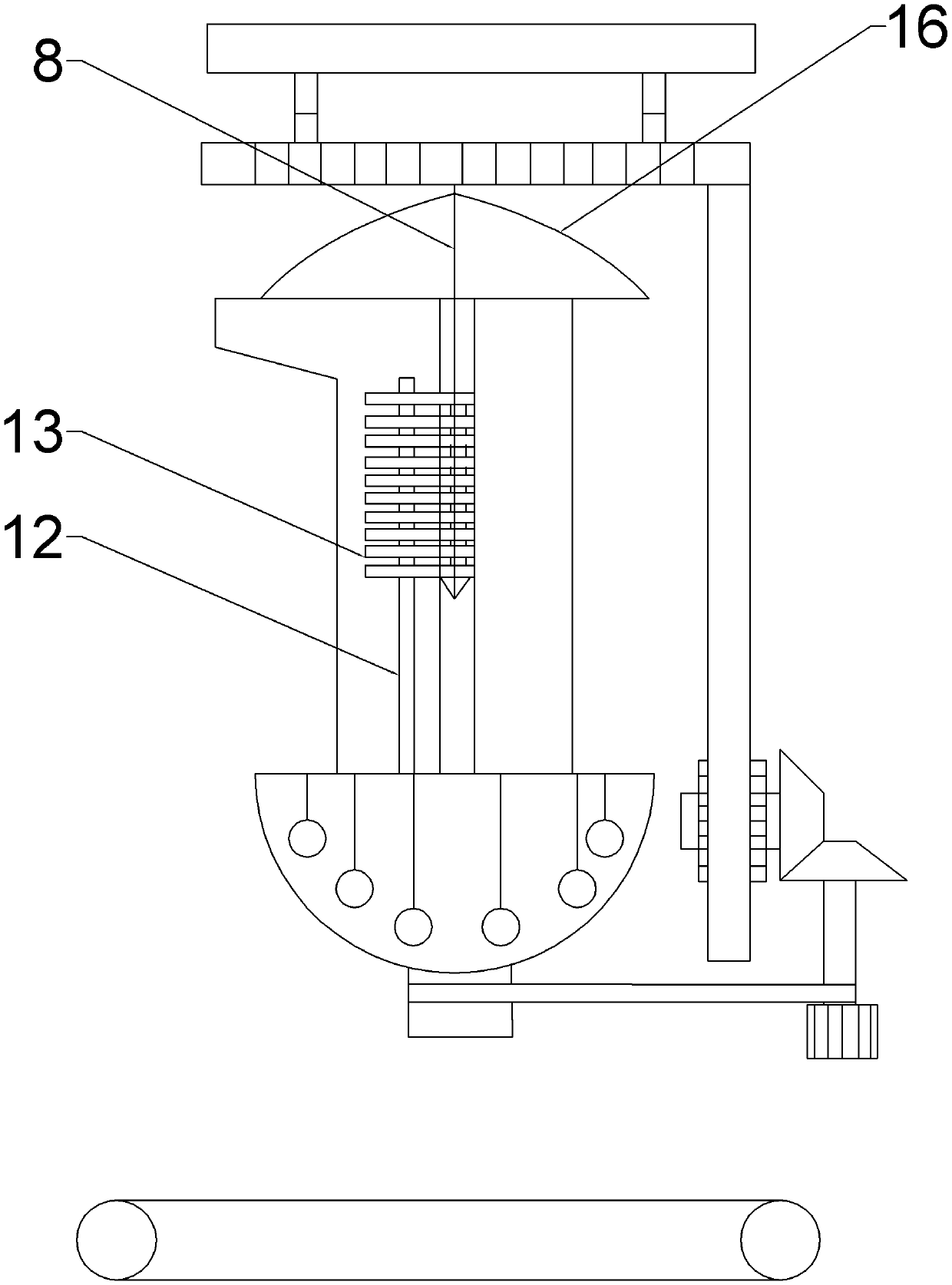

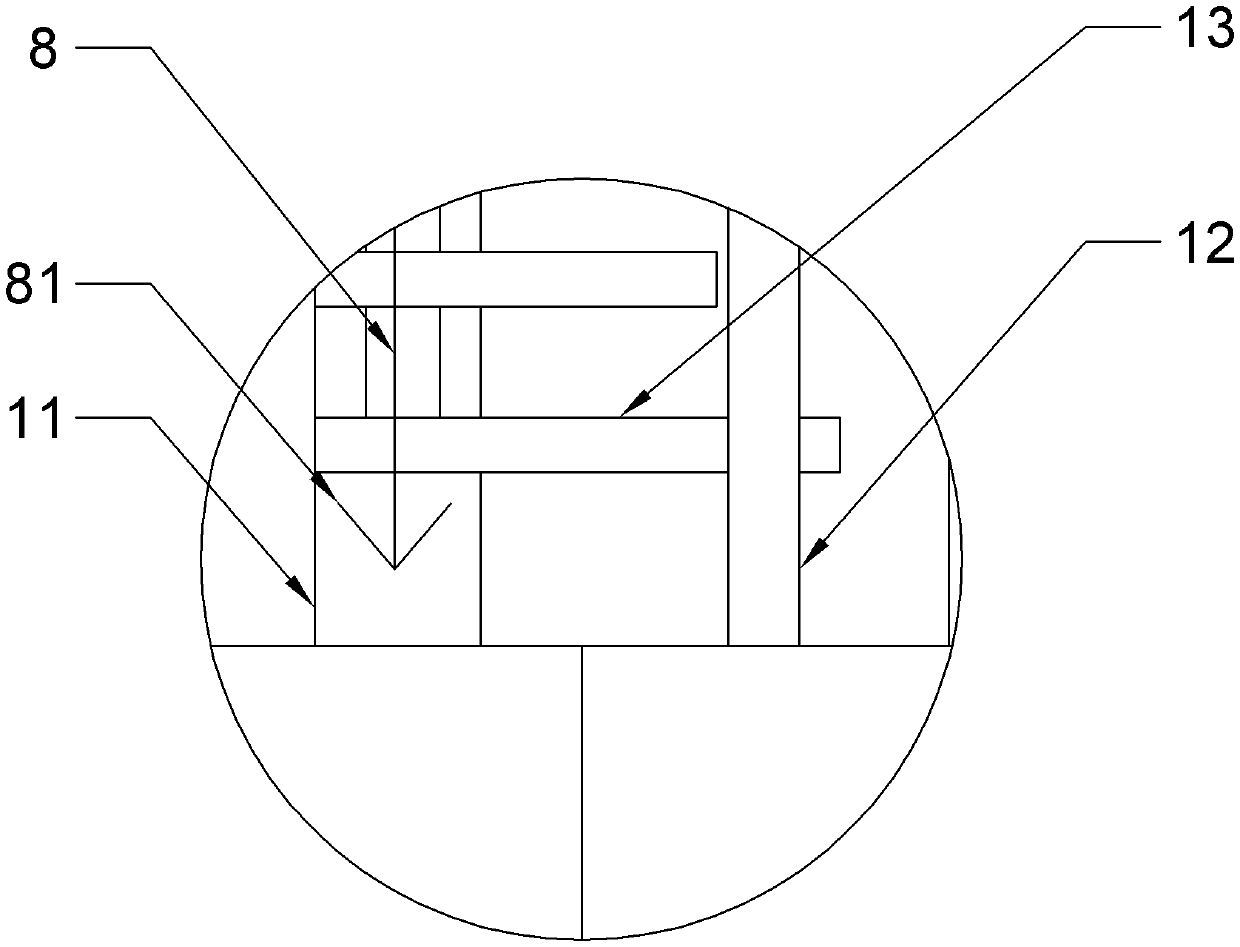

[0022] Reference numerals include: first mixing chamber 1, slide bar 11, vertical bar 12, baffle plate 13, telescopic rod 14, feeding port 15, elastic cloth 16, second mixing chamber 2, vibrating plate 21, elastic cord 22, Ball 23, discharge pipe 24, power supply 3, second conductive block 31, cross bar 4, first conductive block 41, rack 5, motor 6, first bevel gear 61, second bevel gear 62, spur gear 63 , belt 64, conveyor belt 7, launch rod 8, pallet 81.

[0023] like figure 1 Shown, a kind of mixing technology of fermented grains of wine, comprises:

[0024] 1. Install the mixing device, including:

[0025] A, first make the first mixing chamber 1, on the inner wall of the top of the first mixing chamber 1, fixedly connect the slide bar 11 of the inner hollow, then movably connect some spiral distribution baffle plates 13 on the slide bar 11, and in several baffles Connect telescoping rod 14 between plate 13, put into a launching rod 8 in the inside of slide rod 11, be p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com