Method and system for recovering aroma substances in production process of instant coffee

An aroma substance and production process technology, applied in the direction of coffee spice and the like, can solve the problems of great influence on the aroma quality of instant coffee, damage, loss of volatile aroma substances, etc., and achieve the improvement of quality, low energy consumption and production cost saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

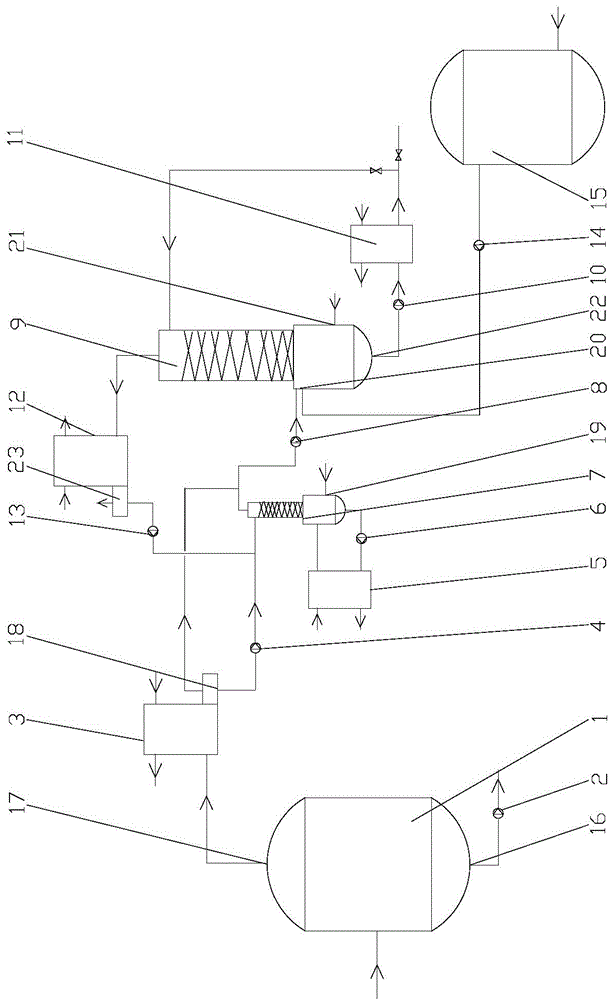

[0027] like figure 1 As shown, a system for recovering aroma substances in the production process of instant coffee, the system comprises a flash tank 1, a water pump I2, a plate heat exchanger I3, a water pump II4, a plate heat exchanger II5, a water pump III6, a displacement tower 7 , vacuum pump 8, adsorption tower 9, water pump Ⅳ10, plate heat exchanger Ⅲ11, plate heat exchanger Ⅳ12, water pump Ⅴ13, Roots blower 14, collecting tank 15, the outlet 16 at the bottom of the flash tank 1 is provided with a water pump I2 , the top outlet 17 is connected to the plate heat exchanger I3, the outlet 18 of the plate heat exchanger I3 is connected to the top of the replacement tower 7, and the bottom of the replacement tower 7 is provided with a process water inlet 19, a water pump III6 and a plate heat exchanger II5. 7. The outlet at the top of the tower is connected with the vacuum pump 8, and the vacuum pump 8 is connected with the inlet 20 at the bottom of the adsorption tower 9....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com