Bottle cap sterilization method and device

A sterilizing device and bottle cap technology, which is applied in the field of PET bottle cap sterilization methods and devices, can solve the problems of incomplete utilization of chemical agents, increased sewage treatment pressure, and operator hazards, so as to save sewage treatment, promote decomposition, The effect of avoiding harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

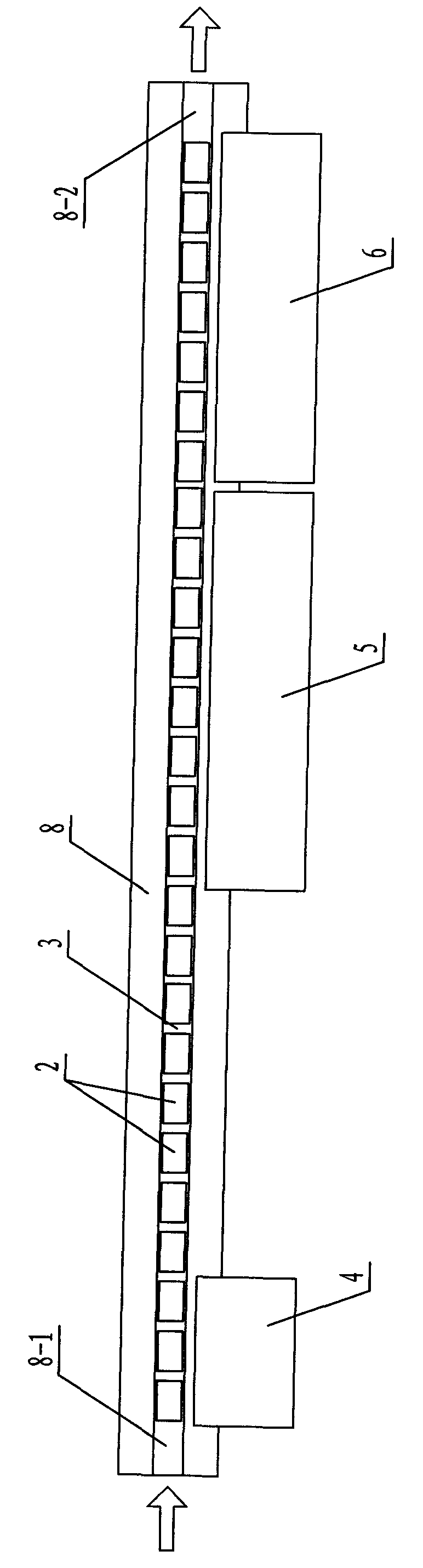

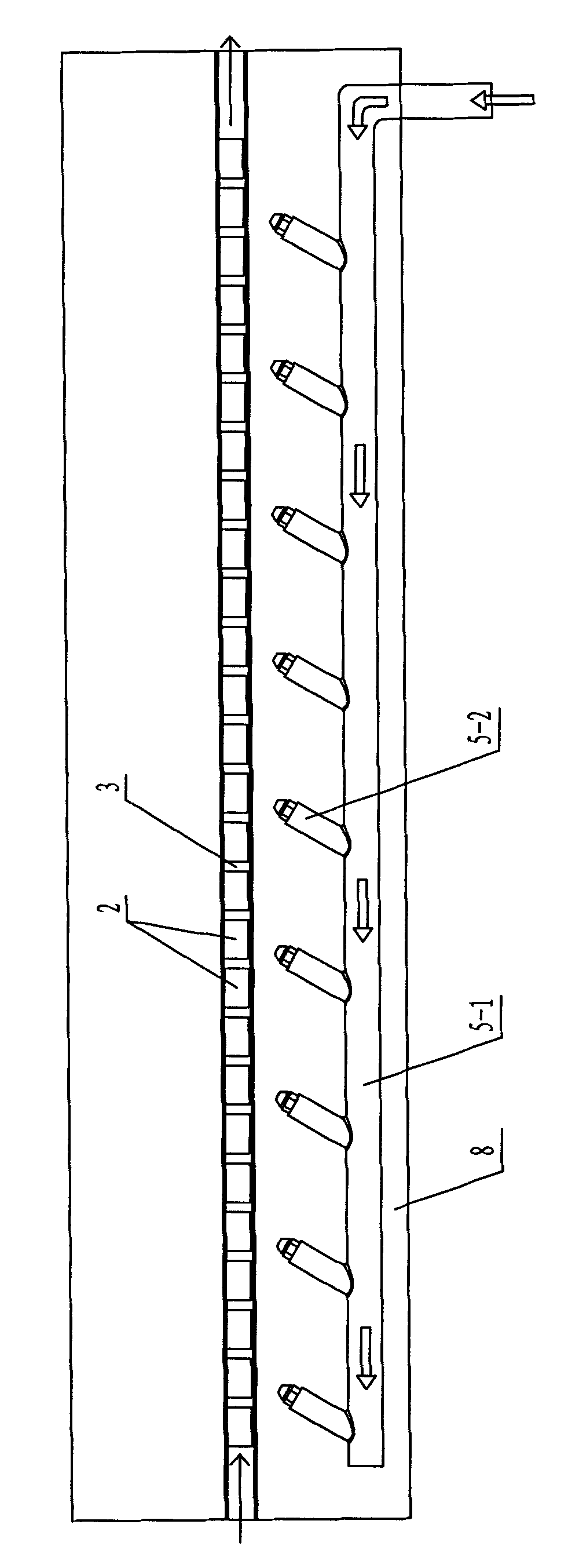

[0034] Such as figure 1 As shown, the sterilization device in the present invention includes a sterilization tunnel 8, a hydrogen peroxide spray module 4, a sterile hot air blowing module 5 and an ultraviolet irradiation module 6.

[0035] The sterilization tunnel 8 is linear, with an entrance 8-1 and an exit 8-2 respectively at both ends, and a linear track 3 arranged along its length is installed inside the sterilization tunnel 8 to move the bottle caps 2 to be sterilized from the entrance 8-1 place is delivered to exit 8-2 place. The hydrogen peroxide spray module 4, the sterile hot air blowing module 5 and the ultraviolet irradiation module 6 are sequentially installed on the side of the sterilization tunnel 8 opposite to the front of the opening of the bottle cap 2 along the direction of movement of the bottle cap 2 (ie, the direction from the entrance to the exit) on the wall.

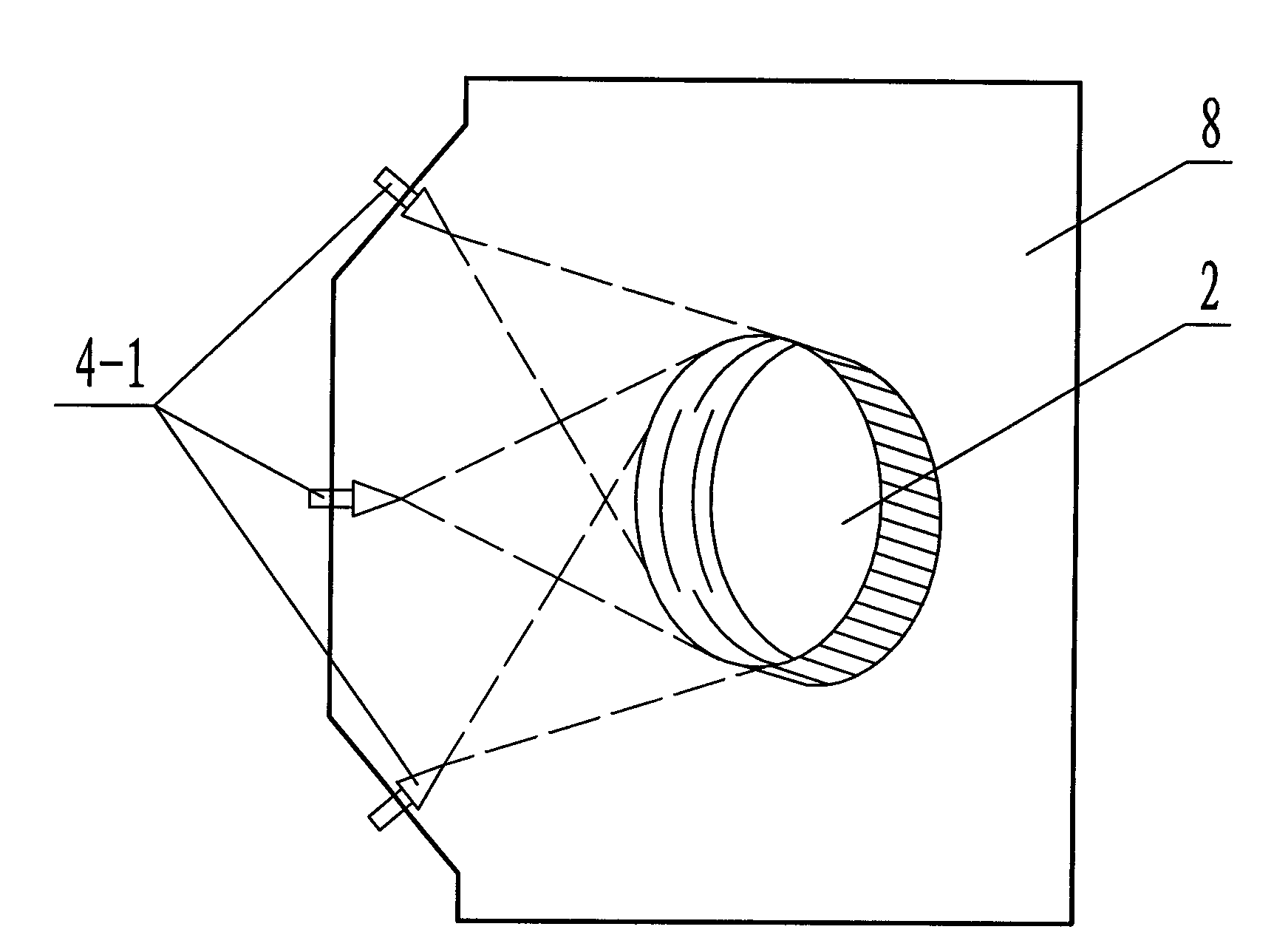

[0036] Such as figure 2 As shown, the hydrogen peroxide spray module 4 is composed of thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com