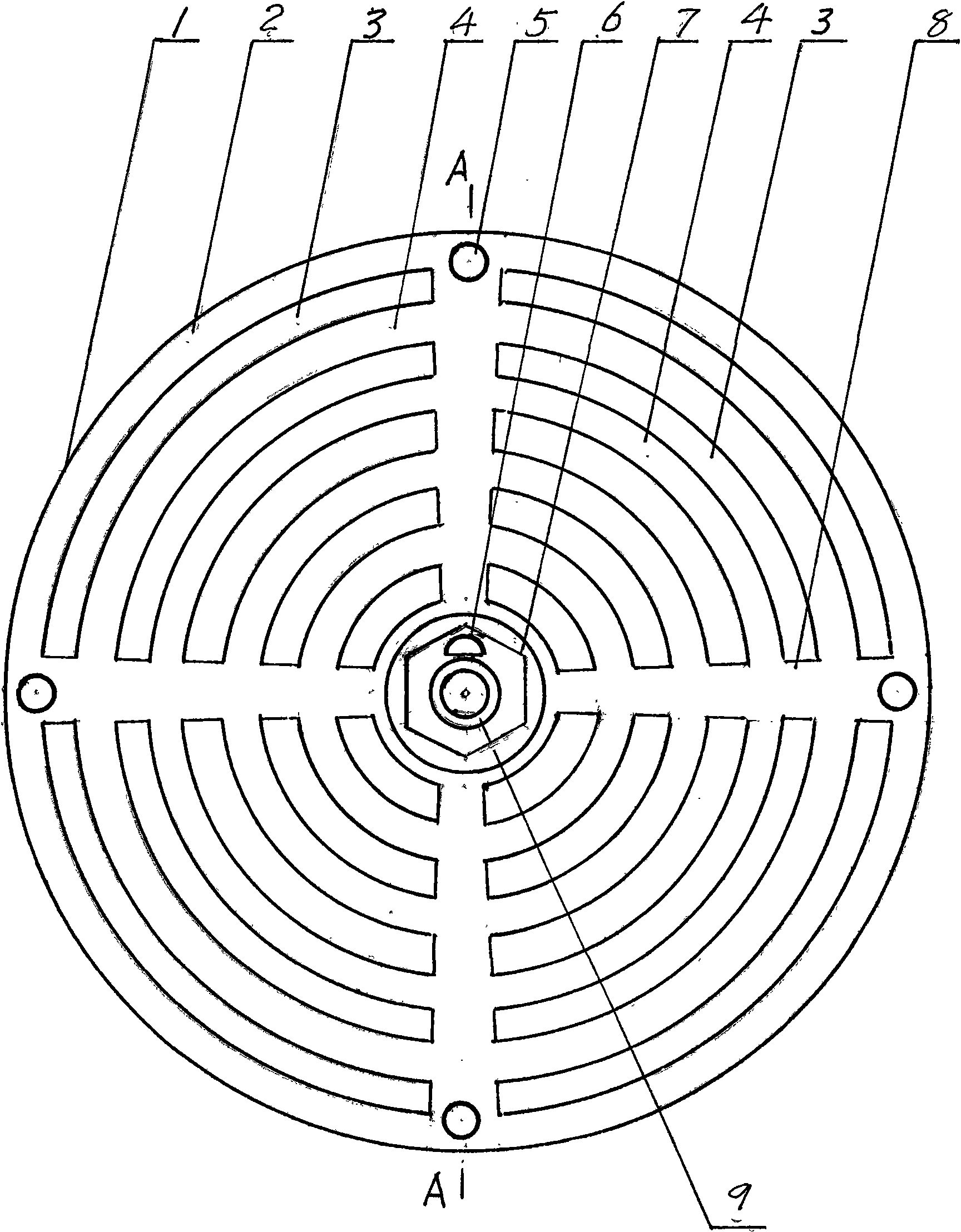

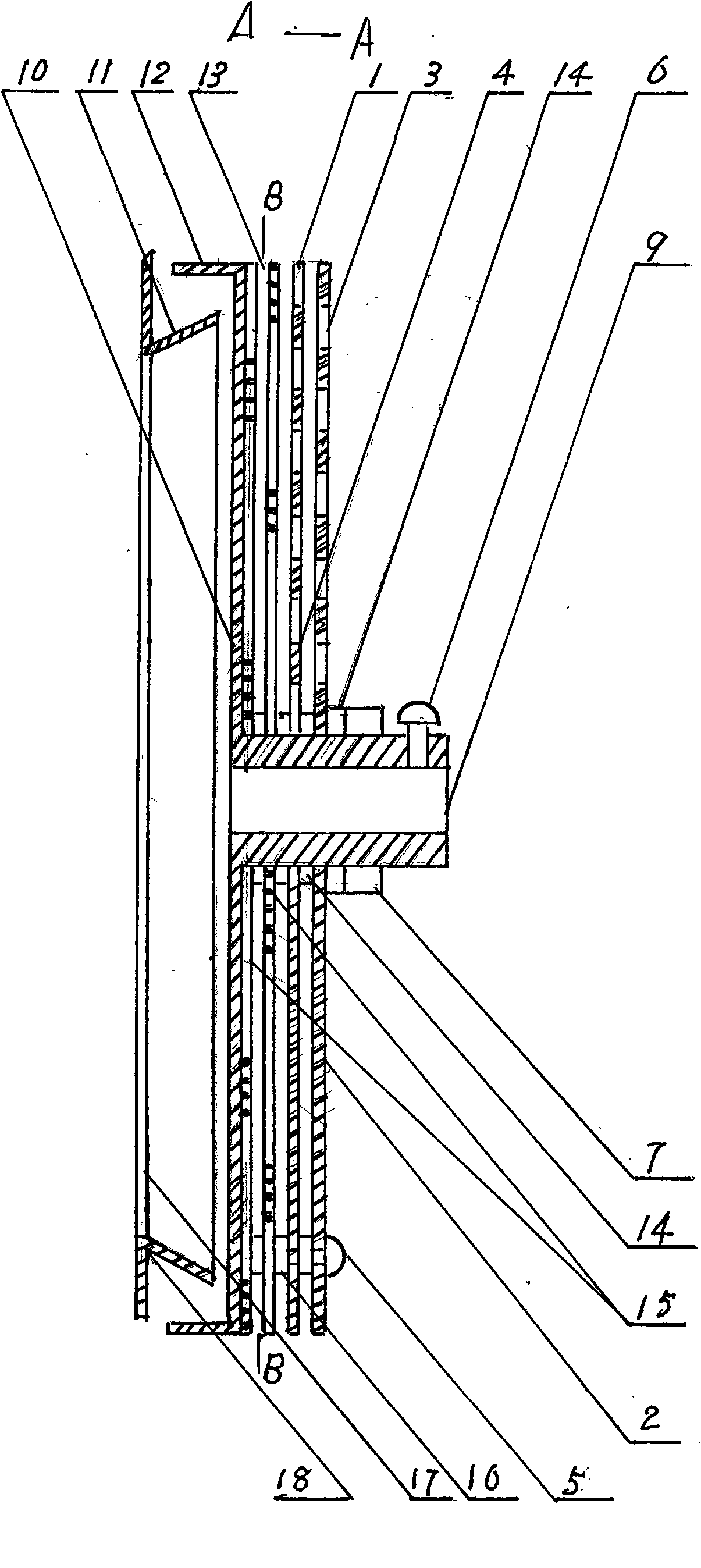

Rotary oil smoke purifier

A kind of lampblack purifier and rotary technology, applied in the direction of removing lampblack, chemical instruments and methods, heating methods, etc., can solve the problems of difficult brushing, affecting air permeability, troublesome and expensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

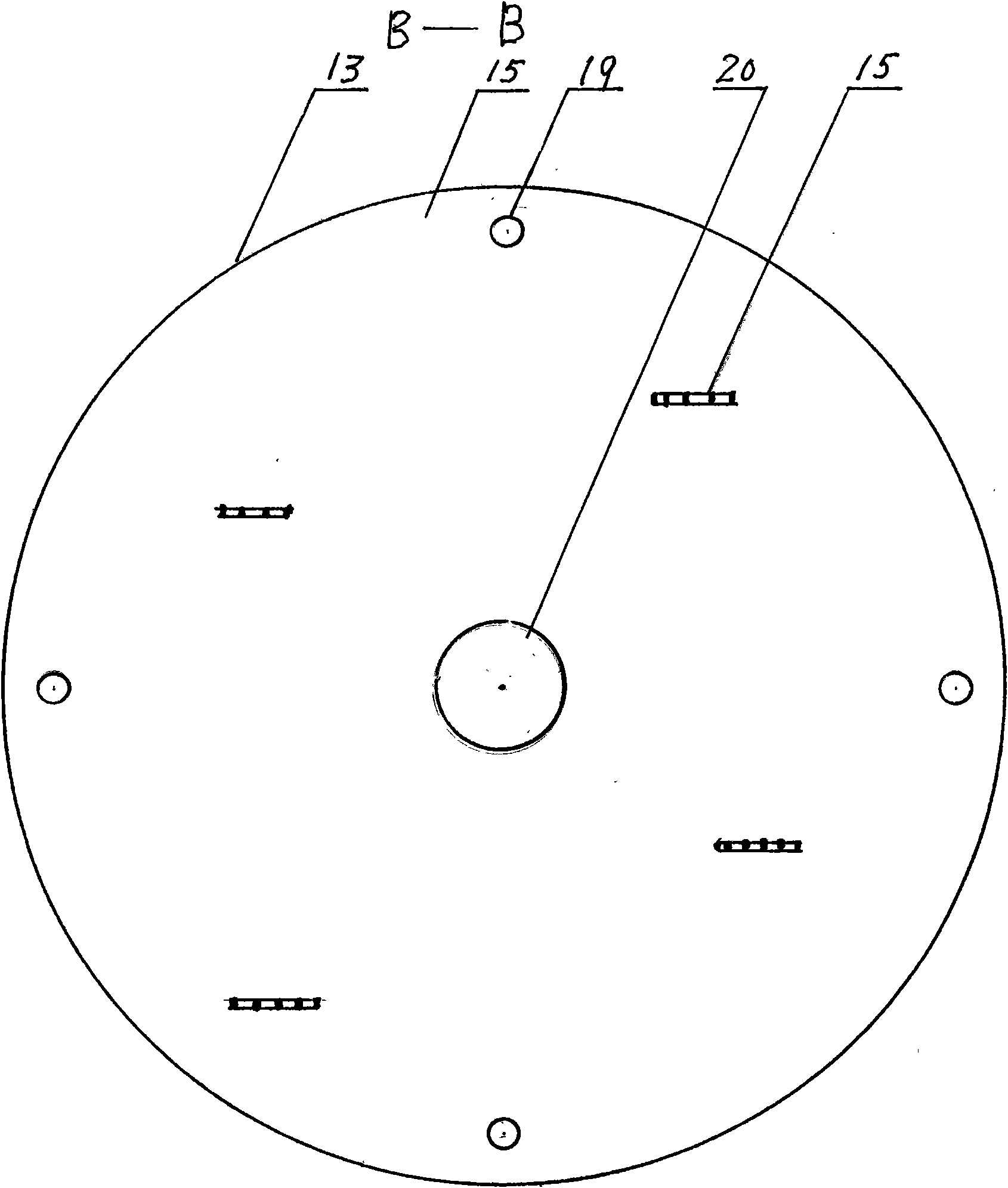

[0031] Embodiment 2, with Figure 14 As shown, compared with embodiment 1, there is no difference in the main structure, and the difference is the oil filter body 13, which is characterized in that the two-layer filter screen 15 is changed to one layer of filter screen 15, and one deck of circular oil removal is added. Sheet 2, the conical oil blocking ring 11, is designed to have a diameter smaller than the diameter of the circular oil blocking ring 12, forming a side oil blocking ring 25, and one end is welded on the side of the suction hole of the exhaust device to form an oil flow groove 18 with a limit.

[0032] In the same way, according to the present invention, a technical solution is given, and multiple rotary oil fume purifiers, 1 layer, 2 layers, 3 layers of filter screens, 1 piece, 2 pieces, 3 pieces of circular oil removal sheets... ..., remove the filter screen 15, increase the round oil removal sheet 2, 3, 4, 5... It is characterized in that, between each layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com