Vacuum freeze-drying processing method for compound fruit and vegetable peanut butter granules

A technology of vacuum freeze-drying and processing method, applied in the fields of application, food preparation, food science, etc., can solve the problem of insufficient nutrition, and achieve the effect of long shelf life and good palatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

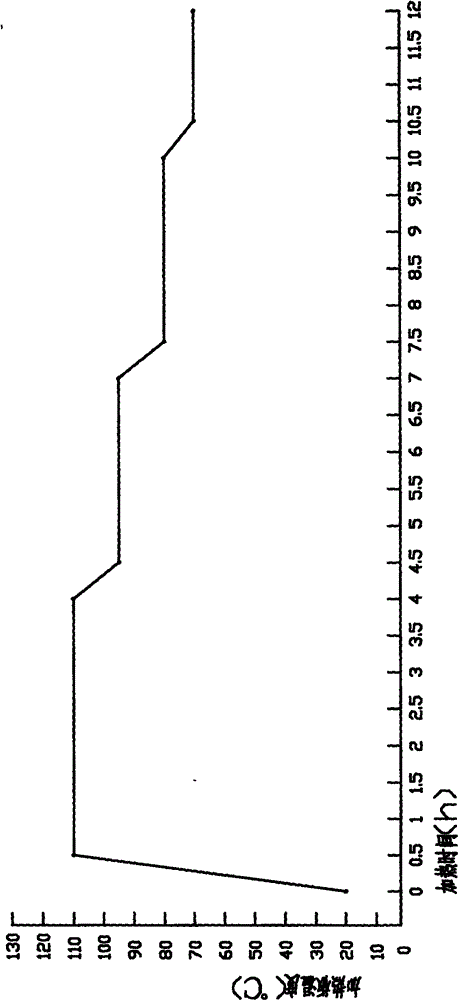

Image

Examples

Embodiment Construction

[0022] The processing method of vacuum freeze-drying composite fruit and vegetable peanut butter grains is as follows:

[0023] a. Material selection: raw materials are composed of the following proportions by weight, wherein peanut butter 70, apple 7, banana 7, green bean 2, carrot 3, sweet potato 3, broccoli 2, potato starch 0.5, sucrose fatty acid ester 0.3 and pectin 2 ;

[0024] b. Mudification: Put the potato starch into the peanut butter according to the above weight ratio, fully chop and mix evenly to be muddy;

[0025] c. Gelatinization: put sucrose fatty acid ester and pectin in the peanut butter in step b, mix them well and heat them evenly, the heating time is 6-8 minutes, and the heating temperature is 60°C-70°C , and keep stirring during the heating process to prevent the pot from sticking;

[0026] d. Pretreatment of fruit and vegetable ingredients: 1.) Apples: select fresh ordinary apples as raw materials, clean the silt on the surface of the apples, peel and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com