Device and method for improving casting blank quality of continuous casting production

A billet and quality technology, applied in the field of metallurgical process control, to achieve uniform temperature distribution, avoid surface cracks and center cracks, and small belly volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

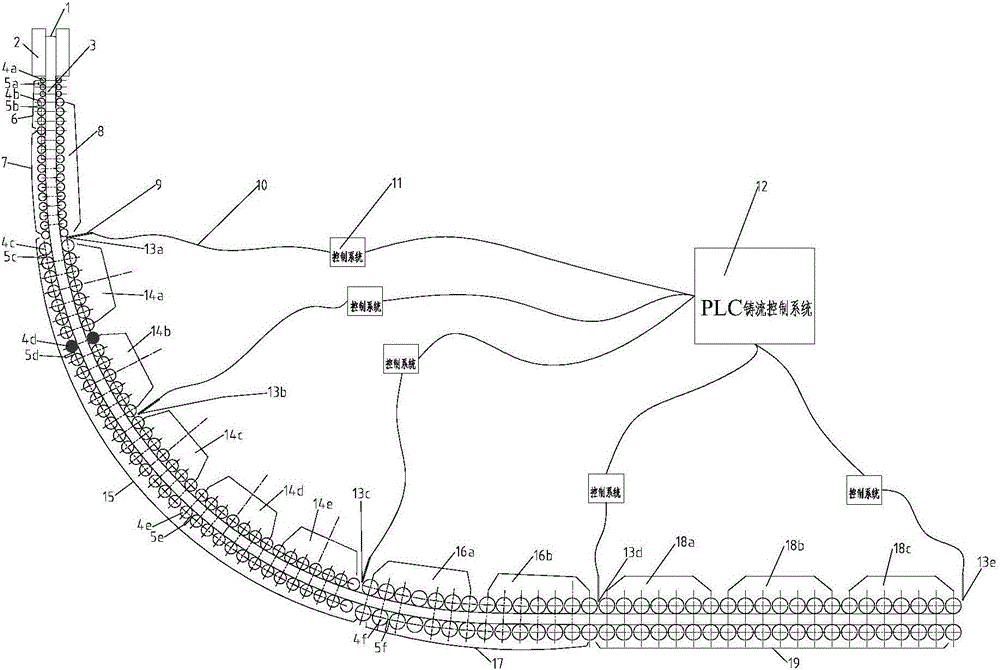

[0050] The device for improving the quality of slabs produced by continuous casting provided by the present invention improves the quality of slabs in continuous casting production through a number of measures, including arranging a plurality of liquid cores artificially forced to form solidification ends along the casting flow direction and large-reduction casting Rolling stand, electromagnetic linear periodic symmetric agitation device, active adjustment secondary cooling water control device based on real-time measurement of slab surface temperature and nozzle upgrade stepless water spray width adjustment.

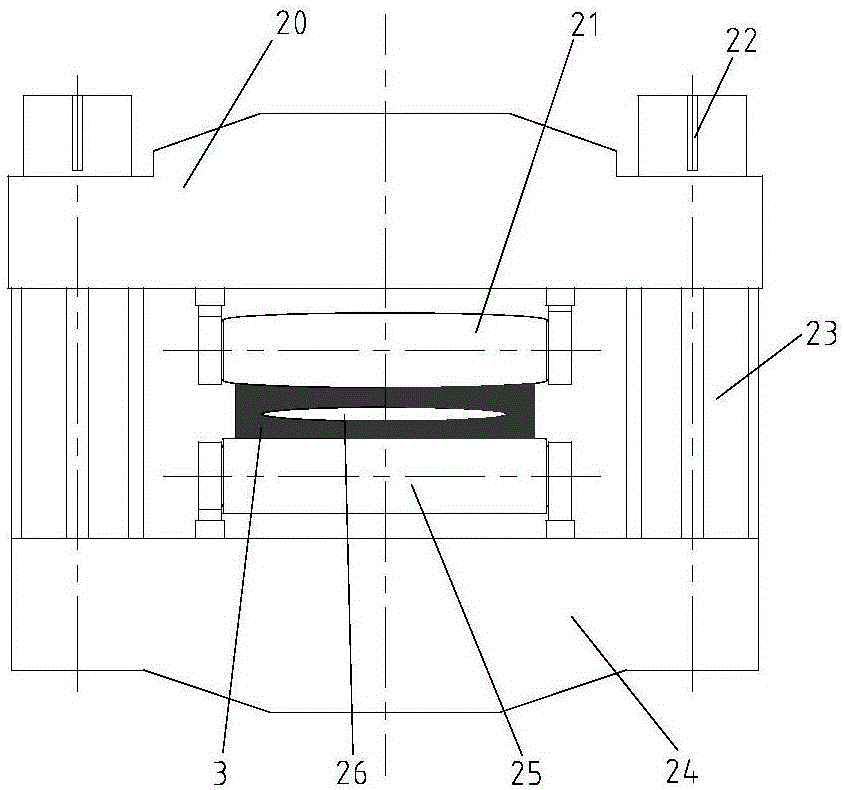

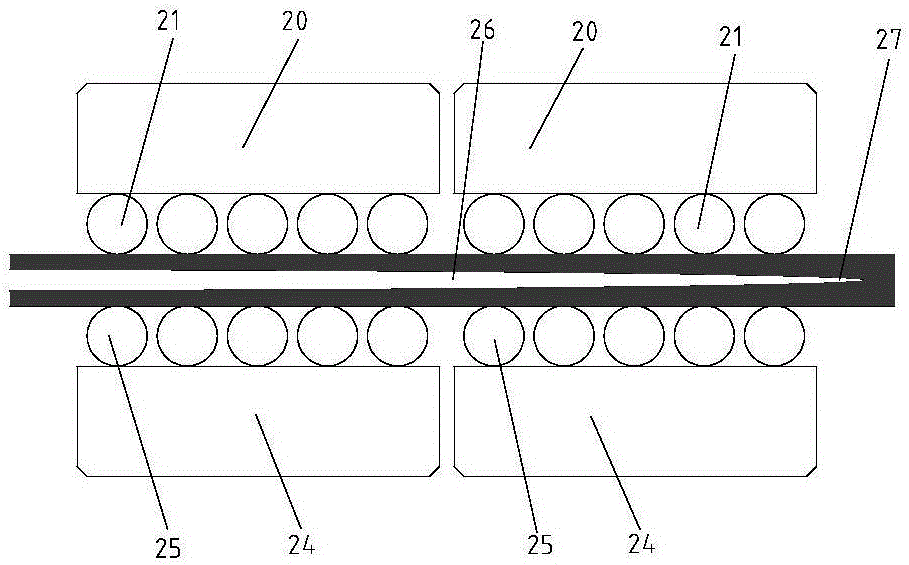

[0051] see Figure 1 to Figure 12 , a device for improving the quality of slabs produced by continuous casting, comprising a plurality of casting and rolling racks 18 arranged along th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com