Physical experiment and numerical simulation combined method for predicting metal extrusion forming cracking

A technology of metal extrusion and numerical simulation, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as public reports of numerical verification of critical damage values that have not been found, and achieve the goal of avoiding surface cracks and internal cracks Formation, high precision, and the effect of reducing the difficulty of measurement

Inactive Publication Date: 2018-11-30

NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

View PDF5 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] After searching the existing literature, no public reports have been found to obtain critical damage values from physical experiments for numerical verification.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0048] The method of this embodiment includes the following steps:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

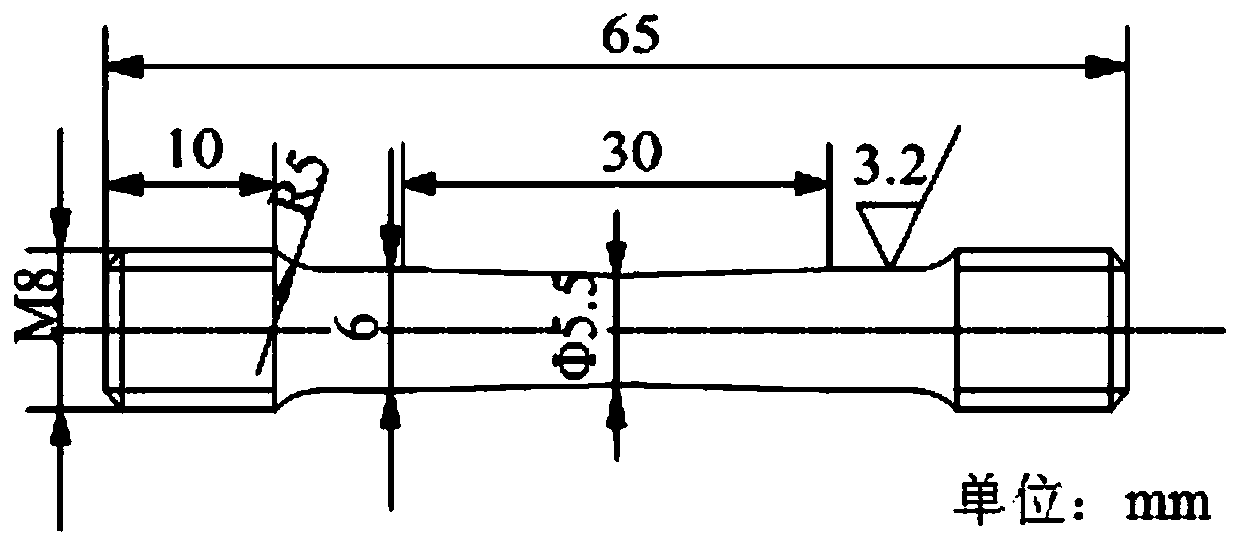

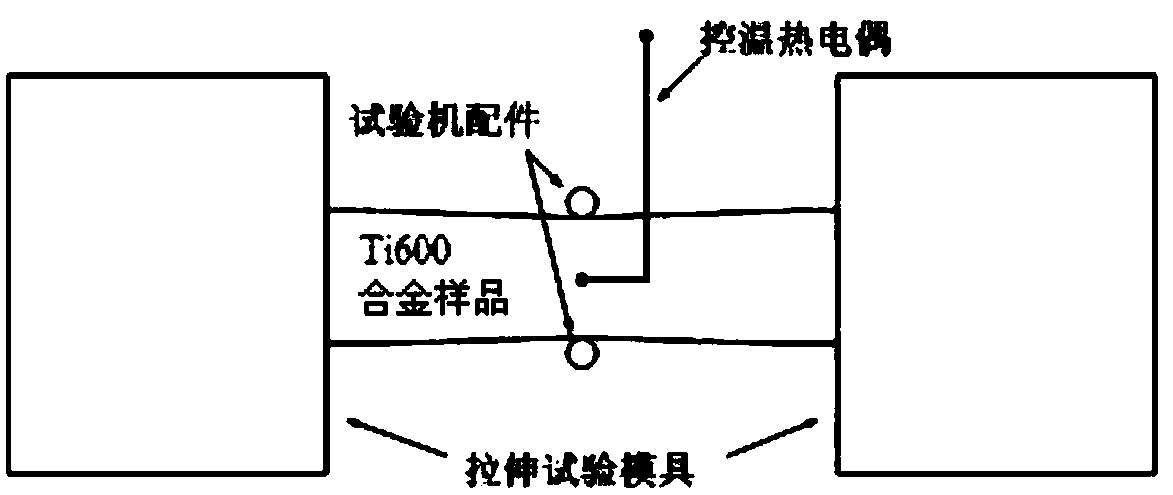

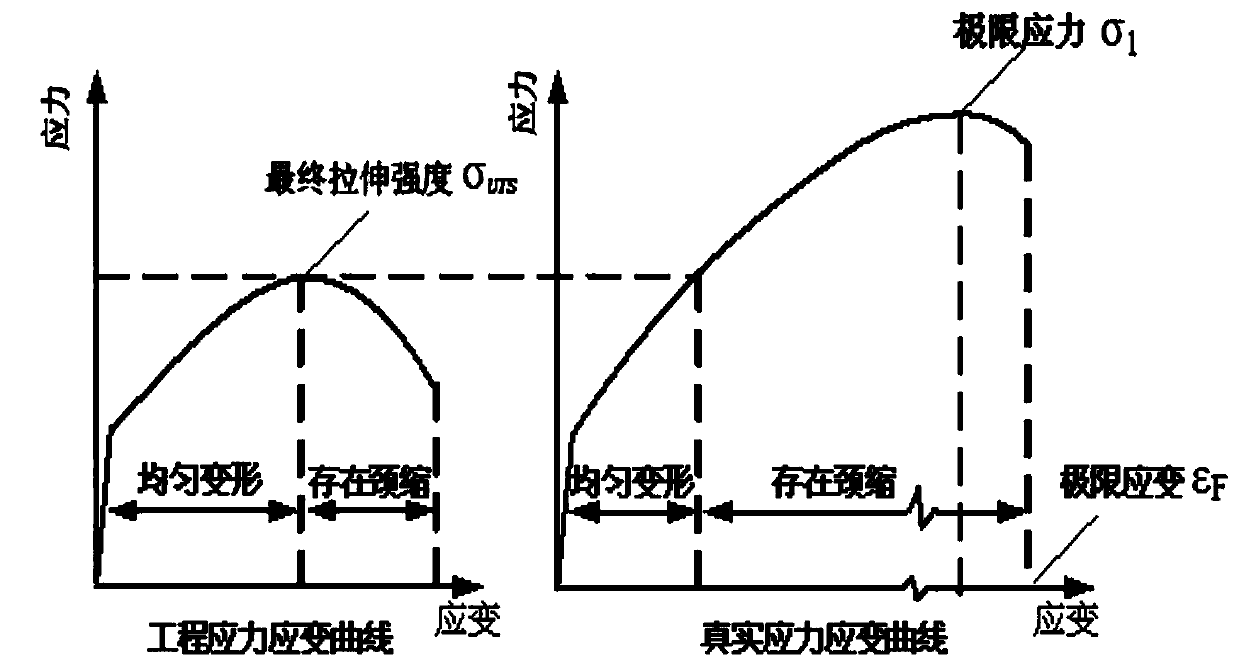

The invention discloses a physical experiment and numerical simulation combined method for predicting metal extrusion forming cracking. The method comprises the steps that first, a hot-stretch test isperformed on metal, and then a Normalized Cockcroft&Latham damage model is selected for calculation to obtain a critical damage value of the metal; second, simulated verification is performed on thecritical damage value of the metal; and third, the critical damage value of the metal after simulated verification is embedded into a metal extrusion finite element model, and the cracking phenomenonin the metal extrusion forming process is predicted. According to the method, a physical experiment and simulated verification are combined to acquire the reliable critical damage value of the metal,then the positions and shapes of metal surface and internal cracks generated in multiple extrusion forming processes are predicted through numerical simulation of the extrusion processes, an error caused by a test mistake is avoided, prediction precision is improved, the prediction range is expanded, therefore, crack generation is avoided, and the quality of metal extrusion pieces is improved.

Description

technical field [0001] The invention belongs to the technical field of metal extrusion cracking prediction technology, and in particular relates to a method for predicting metal extrusion cracking by combining physical experiments and numerical simulations. Background technique [0002] In the metal forming process, due to the complex temperature field conditions and stress conditions, crack defects are prone to occur, resulting in the scrapping of the entire component and bringing huge losses to production. In the process of metal plastic forming, the damage inside the metal is a cumulative process. As the amount of deformation increases, the damage value is also increasing, and when it reaches a critical value, cracks appear inside the metal. Therefore, it is very necessary to predict the occurrence of cracks during metal plastic forming in advance, to manufacture qualified components by optimizing the process, and to ensure the safety and reliability of components in the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G06F17/50

CPCG06F30/23

Inventor 张菁丽毛小南吴金平罗媛媛赵彬郭荻子赵圣泽杨帆

Owner NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com