Mold flux and continuous casting method using the same

A technology of mold slag and continuous casting, which is applied to casting equipment, casting melt containers, and control of molten metal pouring from casting ladles. Quality, suppression of surface cracks, control of heat transfer effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings. However, the present invention is not limited to the following examples. In addition, the present invention can be implemented in many different forms and should not be construed as being limited to the embodiments presented here. Rather, these embodiments are provided so that this disclosure will be thorough and complete, and will fully convey the concept of the present invention to those skilled in the art. In the drawings, the same reference numerals denote the same elements.

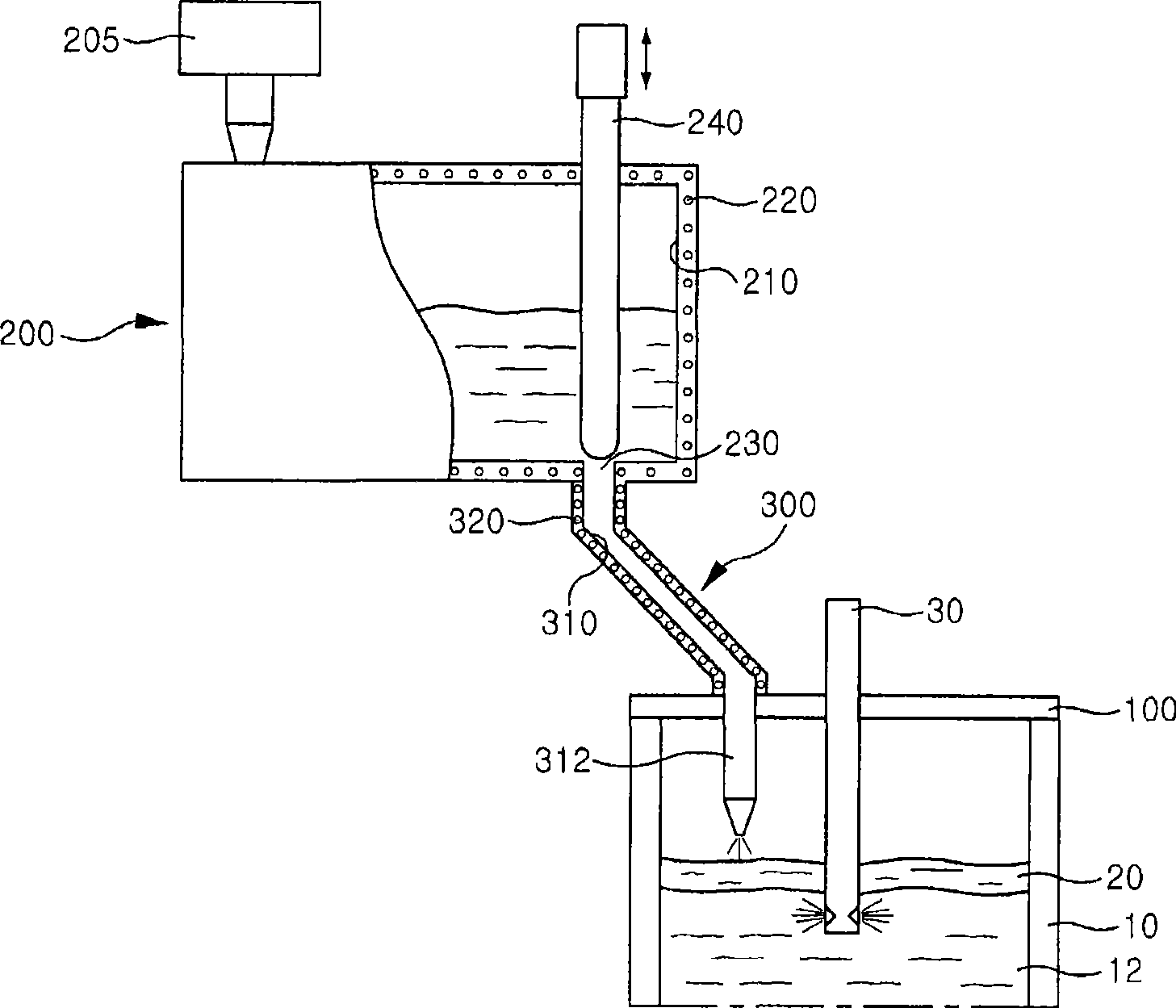

[0033] image 3 It is a diagram showing a schematic structure of a continuous casting machine using molten mold flux.

[0034] Reference image 3 , The continuous casting machine includes: a mold 10; an immersion nozzle 30 for supplying molten steel to the mold 10; a mold cover 100 for covering the upper part of the mold 10; a mold slag melting unit 200 for melting Mold powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Absorption coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com