Self-cooling cotton collection chamber

A cotton collecting room and self-cooling technology, applied in the field of cotton collecting room and self-cooling cotton collecting room, can solve the problems of waste of resources, large floor space, complicated installation of devices, etc., so as to improve the thermal insulation performance and reduce the floor space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

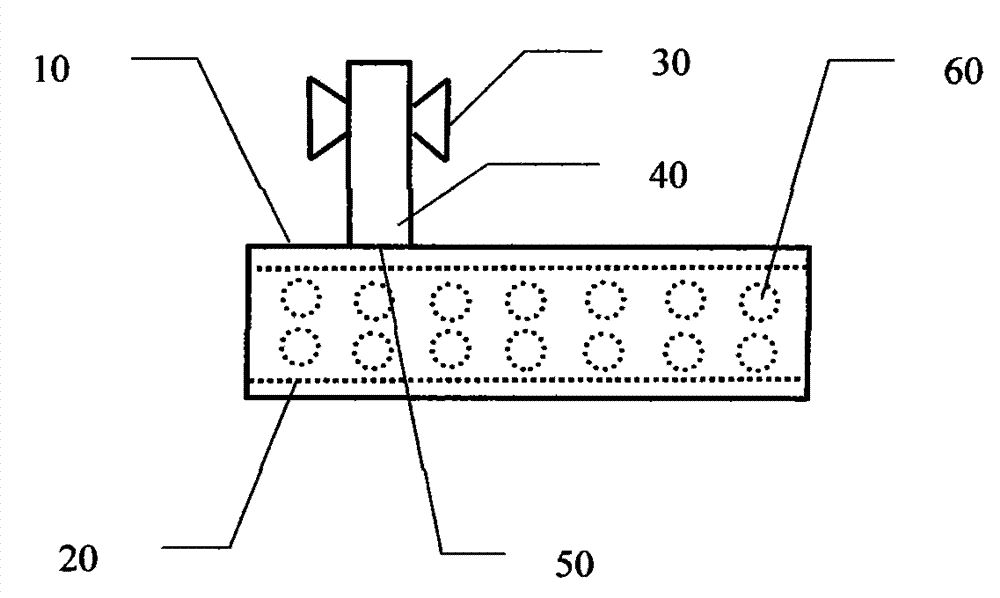

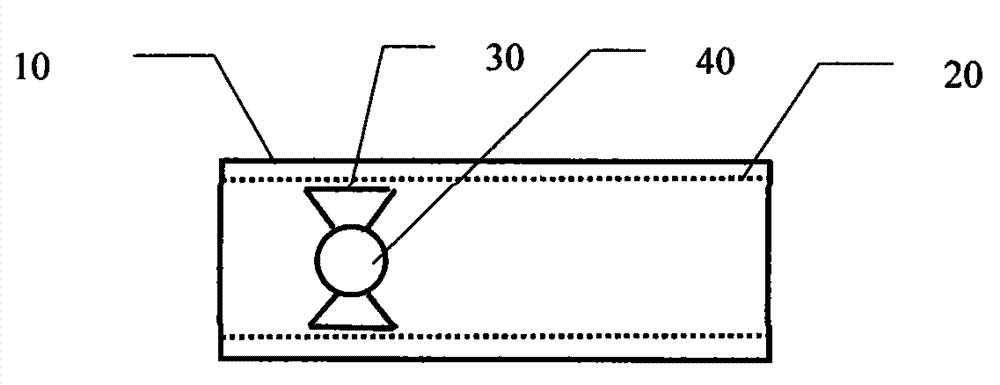

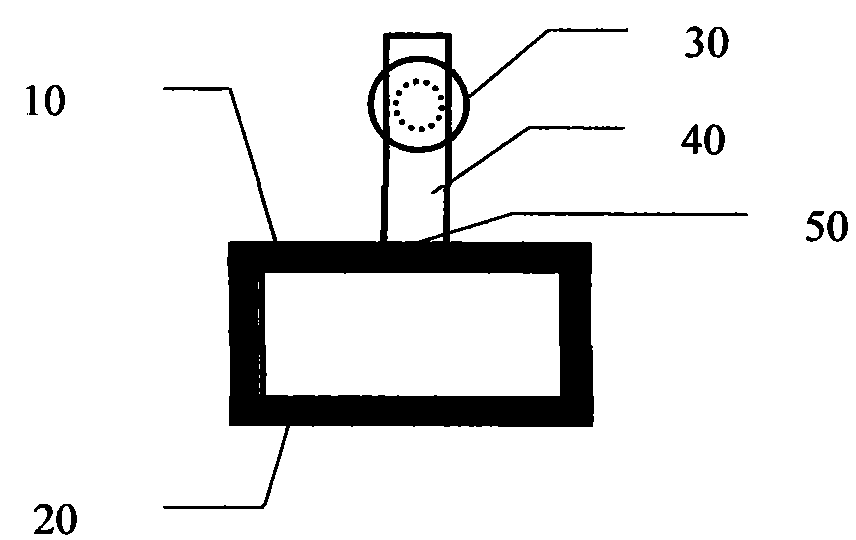

[0020] Such as figure 1 The self-cooling cotton collection chamber includes: a cotton collection outdoor shell 10; a cotton collection indoor shell 20; a bell mouth 30; a cold air pipe 40; an air inlet 50; and a circular air hole 60.

[0021] The cotton collection chamber shell is composed of an outer shell 10 and an inner shell 20; the outer shell is closed as a whole, and the top of the shell is connected to a cold air pipe 40, and there is an air inlet 50 at the junction of the two; The diameter of the air-cooling pipe is 20cm, the temperature is 7°C, the air-cooling pipe is equipped with a horn-shaped air inlet 30; the inner shell is provided with circular air holes 60, which are evenly distributed on both sides of the shell, the diameter is 20cm, and the number is 60 ; The cold air is outside natural air.

[0022] The working process of the self-cooling cotton collection chamber described in this embodiment is as follows:

[0023] 1. The glass liquid is drawn into glass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com