Steel for nuclear-island seamless steel tube and production method thereof

A technology of seamless steel pipe and production method, applied in the field of metallurgy, can solve the problems of reducing the purity of steel, cannot be widely used, and cannot be achieved, and achieve the effects of improving purity, preventing surface cracks, and improving density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

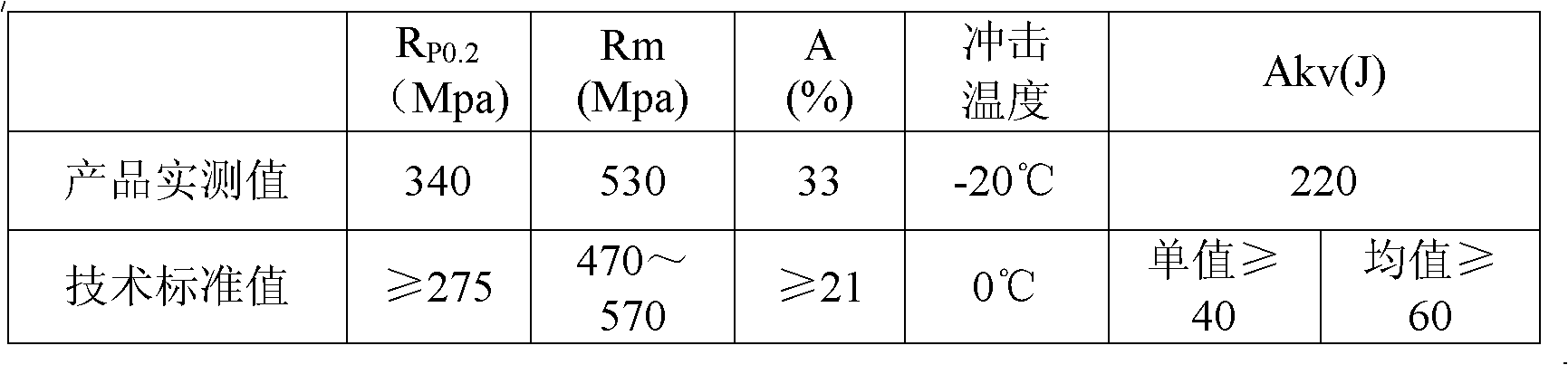

Embodiment 1

[0049] 1. Primary molten steel for electric furnace smelting

[0050] 56 tons of high-quality steel scrap into the electric furnace, 30 tons of molten iron, the main chemical composition of molten iron C: 4.0%, Si: 0.35%, P: 0.09%, S: 0.010%, Fe is the balance, the main chemical composition of high-quality steel scrap C: 0.50% , Si: 0.50%, Mn: 0.70%, P: 0.025%, S: 0.003%, and Fe is the balance. Lime slag dephosphorization, lime consumption 51kg / t steel, oxygen blowing decarburization with oxygen lance, oxygen consumption 41Nm 3 / t Steel. During the tapping process, 13Kg / t of ferroalloy ferromanganese steel and 3.5Kg / t of deoxidizer aluminum balls are added; the electric furnace adopts slag-free tapping. The composition of molten steel for primary electric furnace smelting is C: 0.08%, P: 0.004%, S: 0.024%, and Fe is the balance.

[0051] 2. Refining in LF refining furnace

[0052] The primary molten steel smelted in the electric furnace is refined in the LF refining furnac...

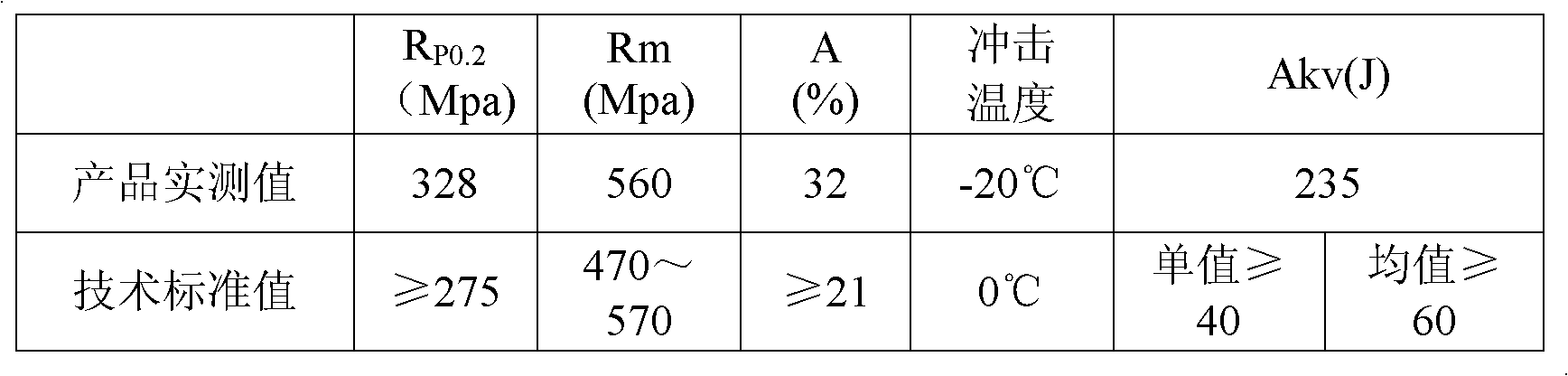

Embodiment 2

[0071] 1. Primary molten steel for electric furnace smelting

[0072] 64 tons of high-quality steel scrap into the electric furnace, 22 tons of molten iron, the main chemical composition of molten iron C: 4.5%, Si: 0.10%, P: 0.020%, S: 0.040%, Fe is the balance, the main chemical composition of high-quality steel scrap C: 0.20% , Si: 0.25%, P: 0.020%, S: 0.018%, and Fe is the balance. Lime slag dephosphorization, lime consumption 42kg / t steel, oxygen blowing decarburization with oxygen lance, oxygen consumption 44Nm 3 / t Steel. During the tapping process, 10Kg / t of ferroalloy ferromanganese steel and 3.5Kg / t of deoxidizer aluminum balls are added; the electric furnace adopts slag-free tapping. The composition of molten steel for primary electric furnace smelting is C: 0.05%, P: 0.0010%, S: 0.024%, and Fe is the balance.

[0073] 2. Refining in LF refining furnace

[0074] The primary molten steel smelted in the electric furnace is refined in the LF refining furnace, and th...

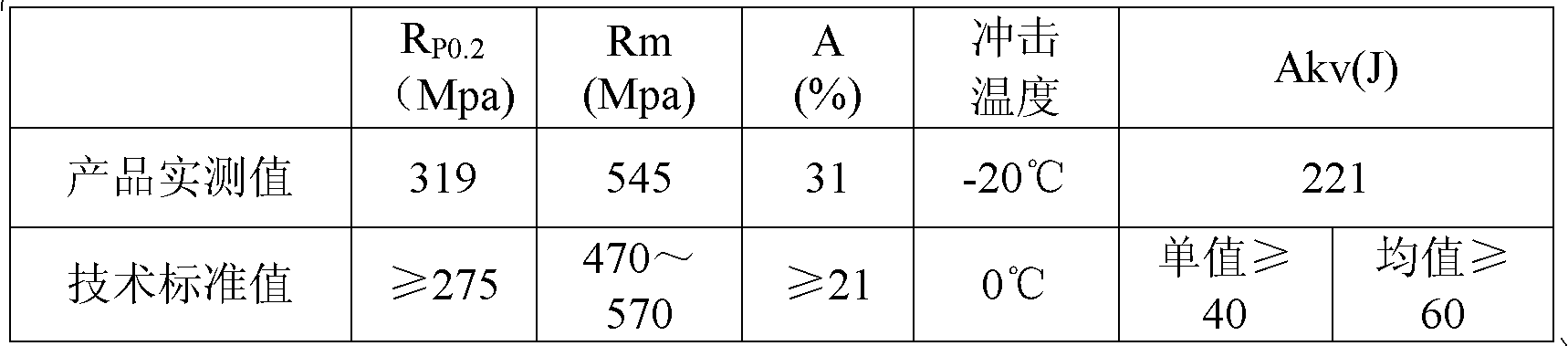

Embodiment 3

[0094] 1. Primary molten steel for electric furnace smelting

[0095] 60 tons of high-quality steel scrap into the electric furnace, 26 tons of molten iron, the main chemical composition of molten iron C: 4.2%, Si: 0.20%, P: 0.045%, S: 0.020%, Fe is the balance, the main chemical composition of high-quality steel scrap C: 0.35% , Si: 0.28%, P: 0.015%, S: 0.010%, and Fe is the balance. Lime slag dephosphorization, lime consumption 46kg / t steel, oxygen blowing decarburization with oxygen lance, oxygen consumption 43Nm 3 / t Steel. During the tapping process, 12Kg / t of ferroalloy ferromanganese steel and 3.0Kg / t of deoxidizer aluminum balls are added; the electric furnace adopts slag-free tapping. The composition of molten steel for primary electric furnace smelting is C: 0.06%, P: 0.003%, S: 0.024%, and Fe is the balance.

[0096] 2. Refining in LF refining furnace

[0097] The primary molten steel smelted in the electric furnace is refined in the LF refining furnace, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com