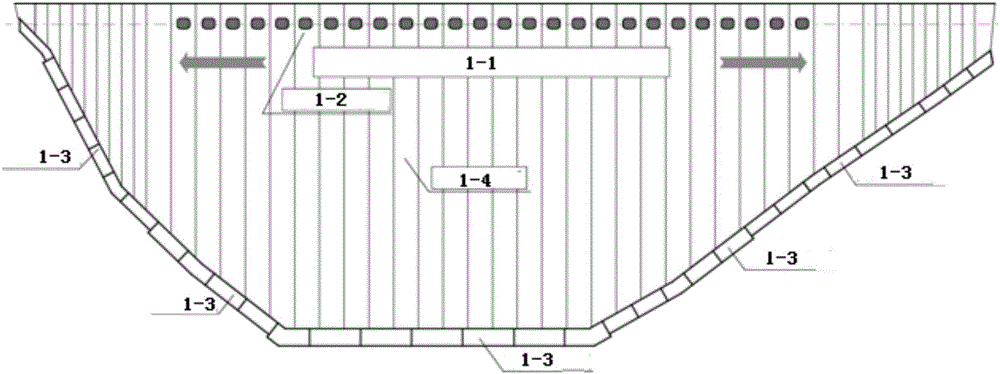

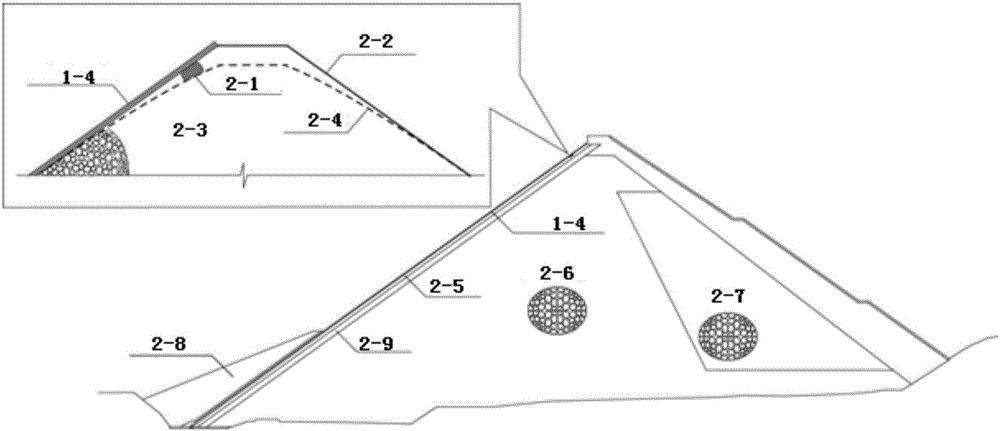

Airbag type automatic protection device for rock-fill dam panel disengagement and design method of device

A technology for automatic protection and rockfill dams, applied in the direction of coastline protection, dams, barrages, etc., can solve problems such as damage, achieve the effect of improving the stress state, preventing surface cracks and staggered platforms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] Example 1: The parameters of a concrete face rockfill dam are listed in Table 1, and the critical void depth of the face plate is determined according to the crack resistance criterion and the fracture resistance criterion respectively.

[0083] Table 1 Calculation parameters of critical voiding of a concrete face rockfill dam

[0084]

[0085] refer to Figure 6-a , Figure 6-b :

[0086] Figure 6-a The relationship between the tensile stress on the surface of the panel and the depth of the void at the void point calculated according to the elastic assumption in the process of voiding the panel is plotted. According to the tensile strength of the panel concrete, it can be calculated that the elevation of the critical void point is about 98.5m, which is also That is, the void depth of the panel determined by the crack resistance analysis is about 1.5m. Figure 6-b The relationship between the void depth determined according to formula (6) and formula (7) and the...

Embodiment 2

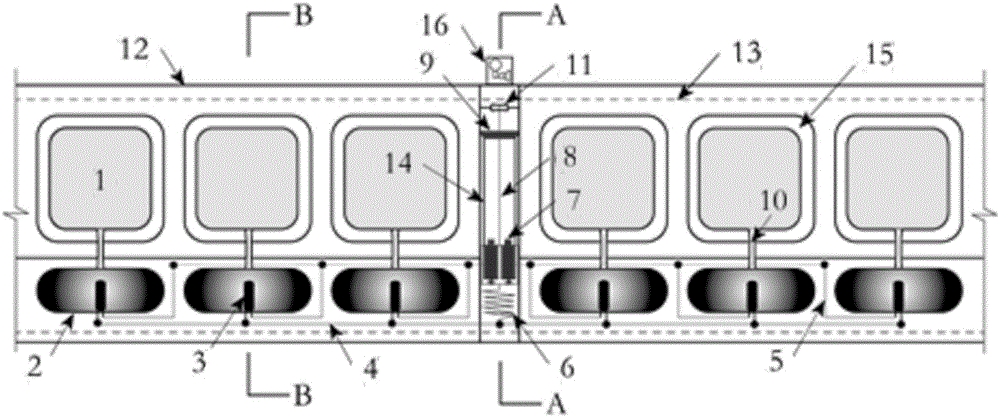

[0102] Example 2: The critical void depth of a concrete face rockfill dam face determined according to the parameters described in Table 1 and the principle of failure resistance is 2m. Now, given the following supplementary conditions, try to determine the longitudinal and latitudinal tensile strength of the protective airbag strength.

[0103] Supplementary parameters of airbag strength determined in Table 2

[0104]

[0105] Figure 9 The requirements for the strength of different numbers of airbags installed according to formulas (9) to (12) are plotted in the figure. It can be seen that the more airbags under a single panel, the higher the requirements for the tensile strength of the airbags. Low, in this case, when the number of protective airbags is 10, the tensile strength is T=T'=6.89kN / m. The material for making the airbag can be selected according to the strength requirement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com