Cold core

A cold core and sand core technology, which is applied in the field of cold core sand core structure improvement and its production, can solve the problems of casting cracking, drape and poor combination of core support, etc., and achieve the effect of reducing use, avoiding poor combination and reducing pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

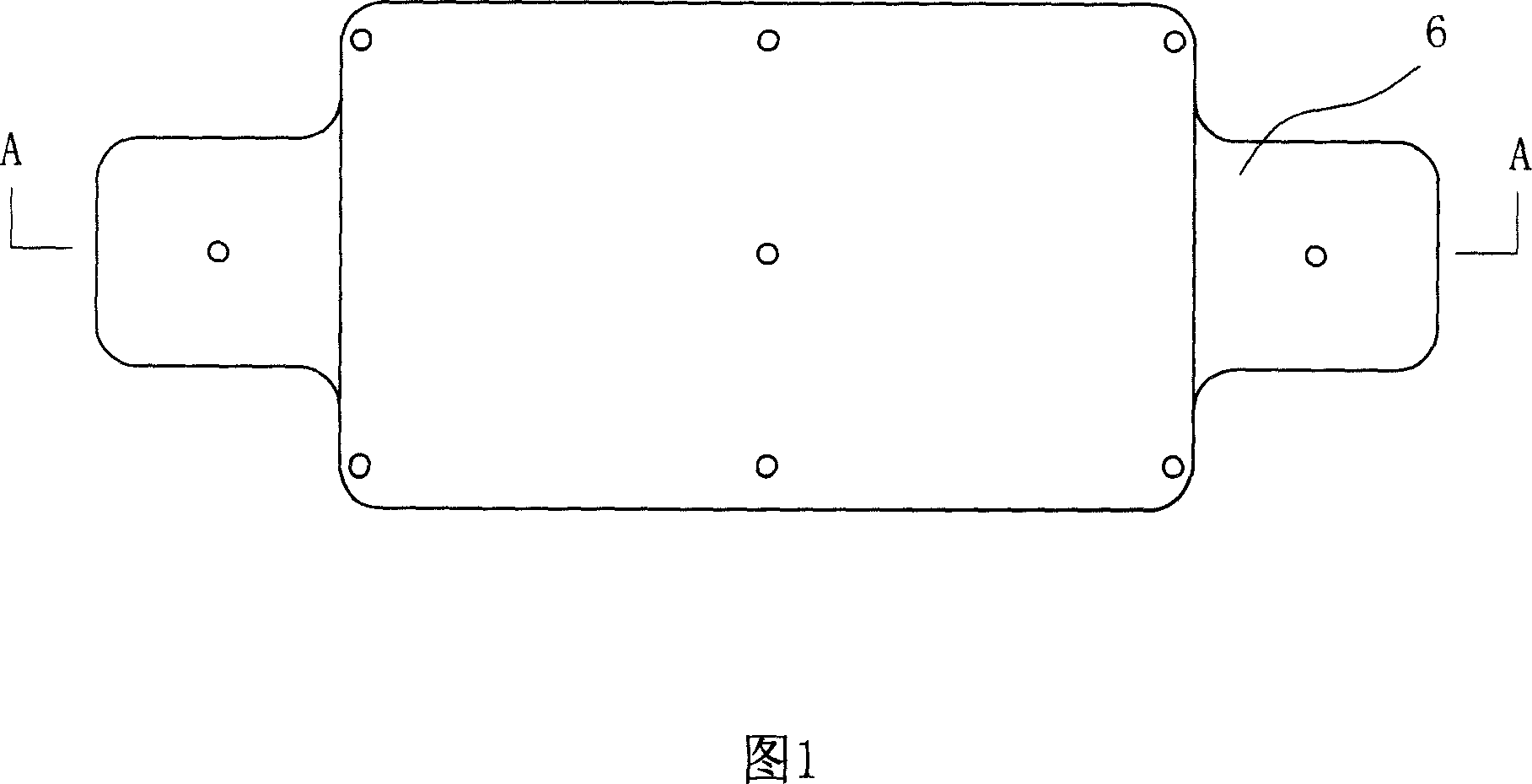

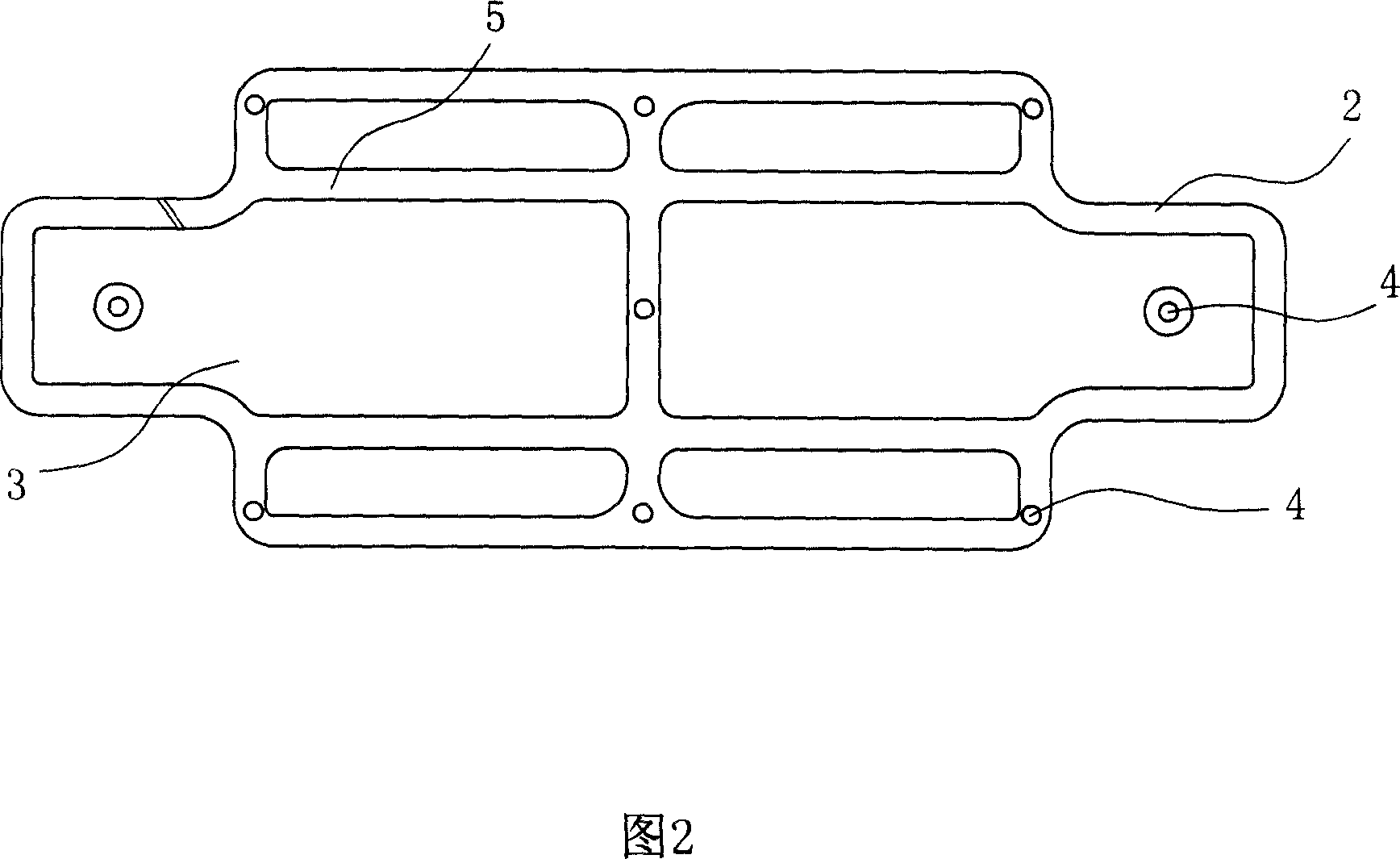

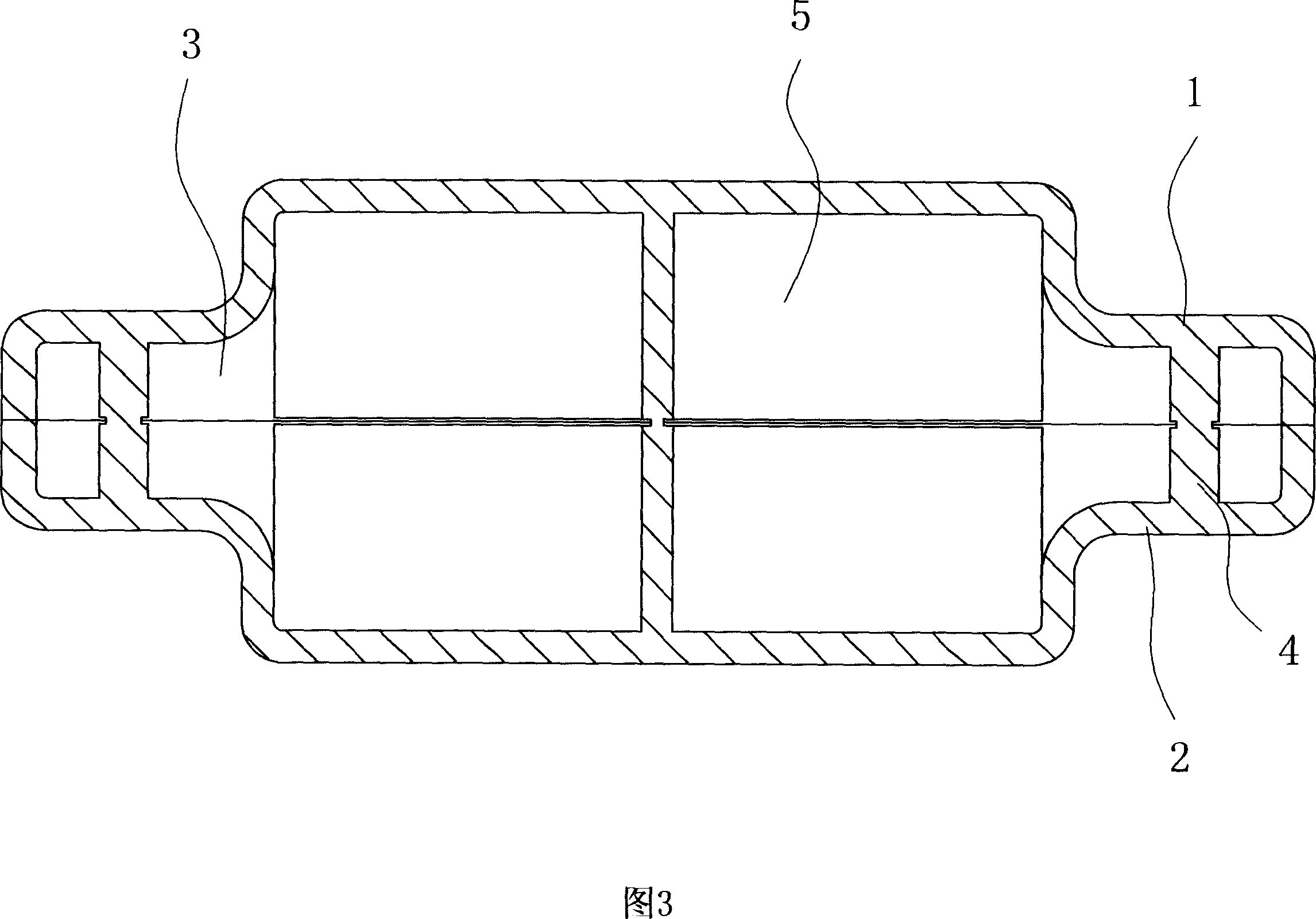

[0028] Embodiment 1: Referring to accompanying drawings 1 to 3, a cold core includes a sand core body 6, the body includes an upper core 1 and a lower core 2, a cavity 3 is provided in the body, and a There are reinforcing ribs 6, and nine connected core columns 4 for connecting the upper core and the lower core. There are three connected core columns arranged on the rib 5, and one connected core column 4 is respectively arranged in the cavity of the left and right wings. The spacing is 200 mm; the wall thickness between the inner wall and the outer wall of the body cavity is 20 mm.

[0029] The manufacturing method of the cold core of the present embodiment comprises the following steps:

[0030] (1) The upper core and the lower core are respectively made by the first and second 3C core shooters;

[0031] (2) Place the sand core of one of the upper core or the lower core in the third 3C core shooting machine, turn the other sand core 180 degrees, and place it in the third 3...

Embodiment 2

[0036] Embodiment 2: A cold core, including a sand core body, the body is mainly composed of an upper core and a lower core, a cavity is provided in the body, the wall thickness of the body is between 10 mm and 60 mm, and the upper core and the lower core are The integral sand core is formed by compounding. In this embodiment, the upper core and the lower core are glued together to form an integral structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com