Non-vacuum production method for CuCrZr alloy wire rod

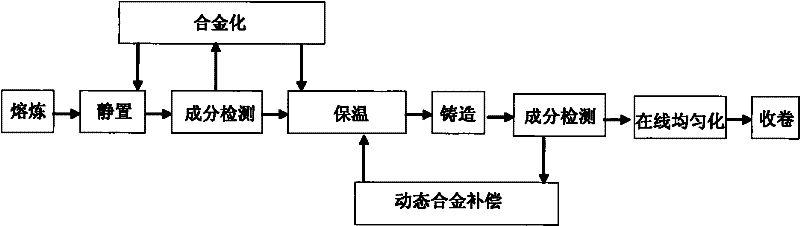

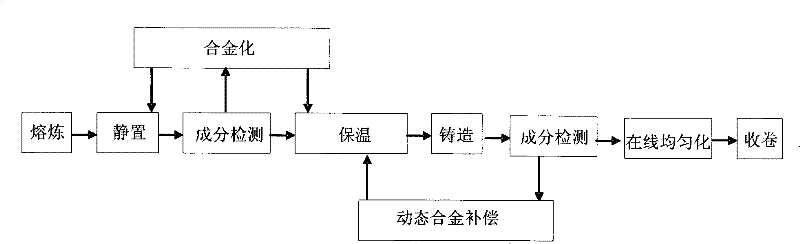

A production method and non-vacuum technology, applied in the field of non-ferrous metal preparation and processing, can solve the problems of inability to realize non-vacuum preparation of CuCrZr alloy wire rods, lack of protection devices and processes, lack of dynamic compensation technology for easily oxidizable alloy elements, etc., and reduce costs. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Prepare the C18100 alloy billet according to the composition range shown in the №I alloy in Table 1. Firstly mix the electric copper and the returned charge, put them into the melting furnace, heat up to 1250-1300°C for melting, after the charge is completely melted, degas and create slag; after standing for 15 minutes, dissolve the primary alloy Cr element into the melting furnace Alloying is carried out in the copper melt, and the Cr element is added in the form of pure metal; the composition is detected by online sampling, and the melt of the melting furnace is transferred to the holding furnace after the composition inspection is passed, and the secondary alloying element Zr is dissolved in the melting furnace of the holding furnace. Secondary alloying is carried out in the body, and Zr element is added in the form of an intermediate alloy; after standing for 10 minutes, when the temperature reaches the casting temperature of 1200-1300°C, casting starts, and the cast...

Embodiment 2

[0027] Prepare the C18400 alloy blank according to the composition range shown in Table 1 №II alloy. Firstly mix the electric copper and the returned charge, put them into the melting furnace, heat up to 1280-1350°C for melting, after the charge is completely melted, degas and make slag; after standing for 20 minutes, dissolve the primary alloy Cr element into the melting furnace First alloying is carried out in the copper melt, and the Cr element is added in the form of pure metal; online sampling is carried out for composition detection, and the melt is transferred to the holding furnace after the composition inspection is qualified, and the secondary alloying element Zr is dissolved into the melt of the holding furnace for secondary alloying. Secondary alloying, Zr element is added in the form of pure metal; after standing for 12 minutes, when the temperature reaches the casting temperature of 1200-1300°C, start casting, and control the casting temperature at 1200-1300°C, th...

Embodiment 3

[0029]Prepare the C18145 alloy billet according to the composition range shown in the №III alloy in Table 1. Firstly mix the electric copper and the returned charge, put them into the melting furnace, heat up to 1300-1350°C for melting, after the charge is completely melted, degas and make slag; after standing for 25 minutes, dissolve the primary alloy Cr element into the melting furnace First alloying is carried out in the copper melt, and the Cr element is added in the form of an intermediate alloy; on-line sampling is carried out for composition testing, and after the composition inspection is qualified, the melt of the melting furnace is transferred to the holding furnace, and the secondary alloy element Zr is dissolved into the holding furnace Secondary alloying is carried out in the melt, Zr element is added in the form of intermediate alloy; after standing for 15 minutes, when the temperature reaches the casting temperature of 1200-1300°C, start casting, and control the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com