Multilayer wall embedded with phase change filling material and provided with cavity

A filling material and phase change technology, which is applied in the field of building walls, can solve the problems of adverse effects on the production and use of building walls, the failure of phase change materials to achieve phase change cycle, and the complicated structure of mechanical devices, etc., and achieve good market application prospects , Improving indoor comfort and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

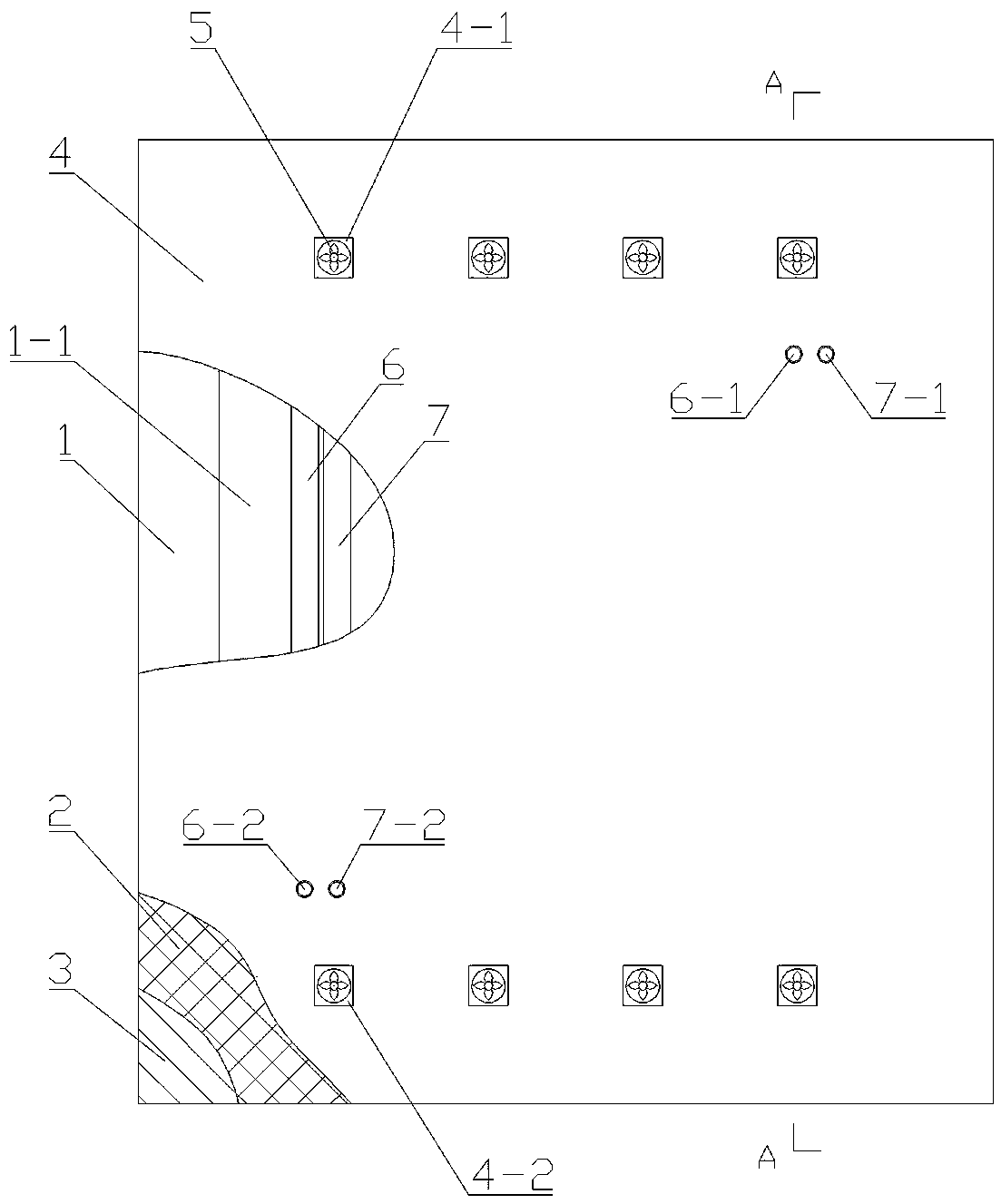

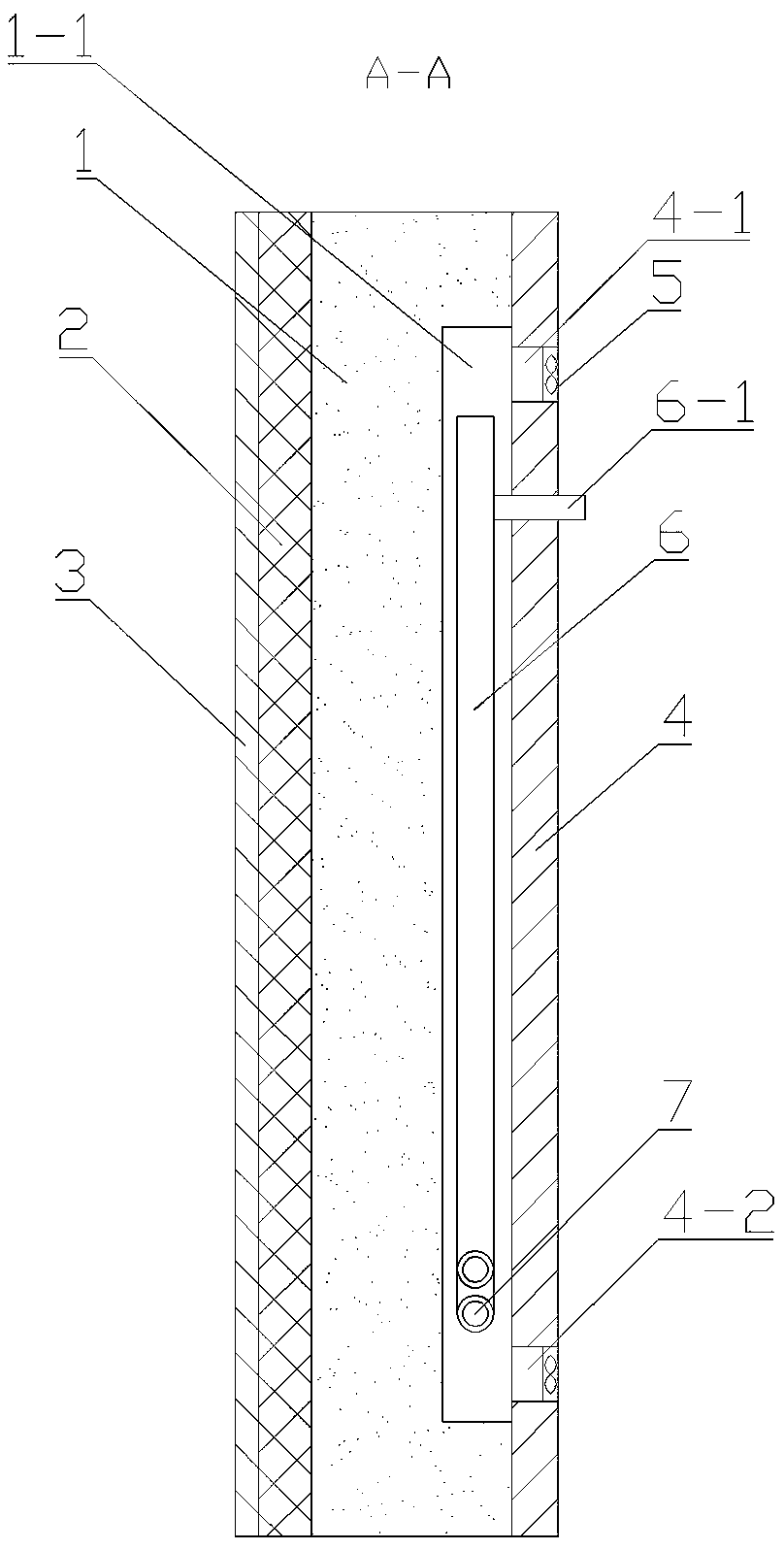

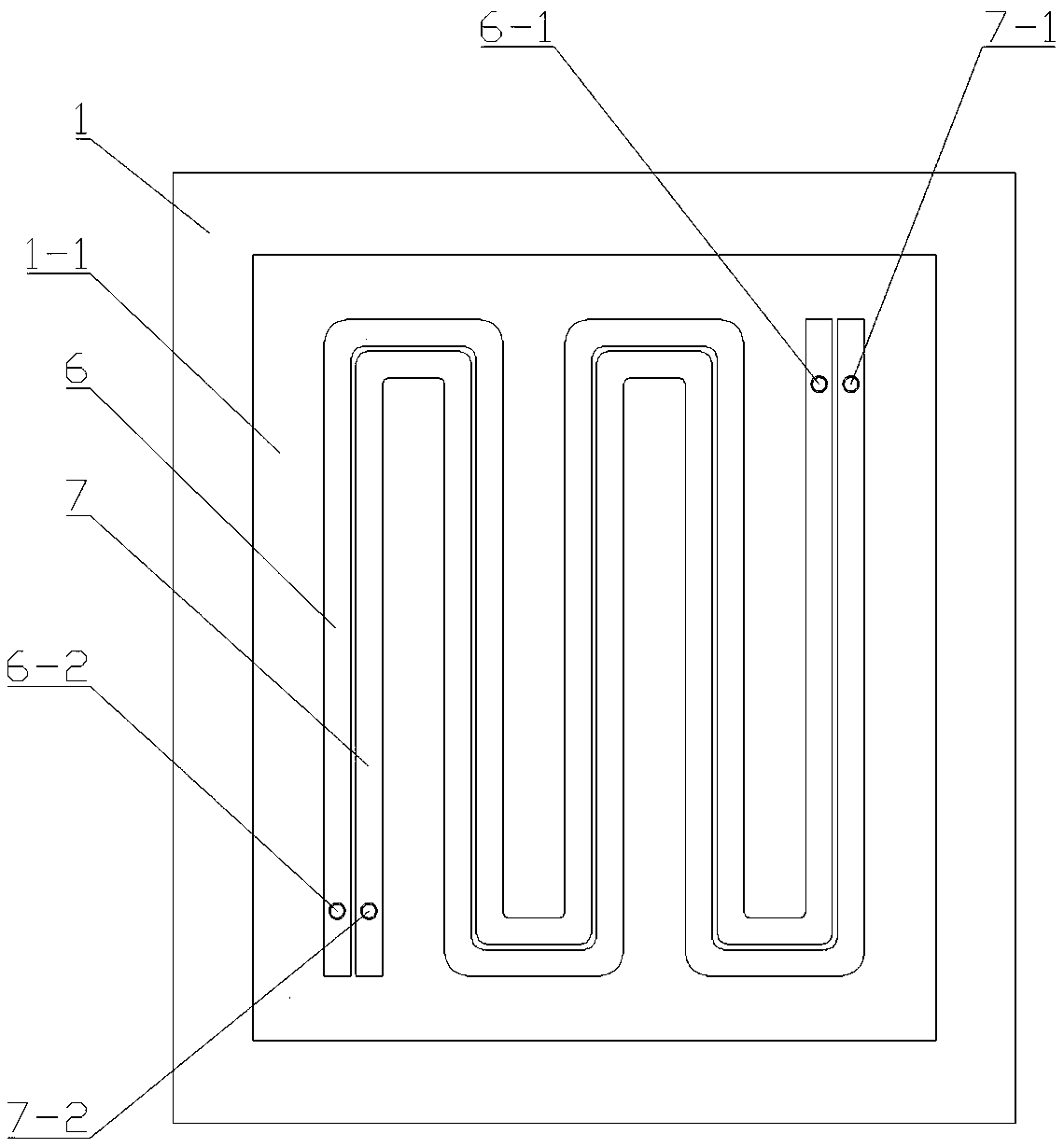

[0029] Embodiment one, such as Figure 1-4 As shown, the multi-layer wall with a cavity built-in phase change filling material includes concrete wall 1, insulation layer 2, reflection layer 3, finish layer 4, fan 5, high temperature phase change material water pipe 6 and low temperature phase change material Material water pipe7.

[0030] A cavity 1 - 1 is provided in the concrete wall 1 close to the finish layer 4 .

[0031] The thermal insulation layer 2 is arranged on the outside of the concrete wall 1 for thermal insulation of the concrete wall 1 .

[0032] The reflective layer 3 is arranged close to the outer side of the thermal insulation layer 2, and it is made of a high-reflectivity coating, which can resist part of the solar radiation and reduce the heat from the outside into the room.

[0033] The upper end of the facing layer 4 is provided with a plurality of upper air outlets 4-1, and the lower end is provided with a plurality of lower air outlets 4-2, each upper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com