Method and device for controlling direct-current generator set of coal-fired boiler

A technology for generator sets and coal-fired boilers, which is applied to the control system, control of water supply, engine components, etc., can solve problems such as damage, output power unfavorable grid voltage, etc., and achieve the effect of reducing the degree of fluctuation and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

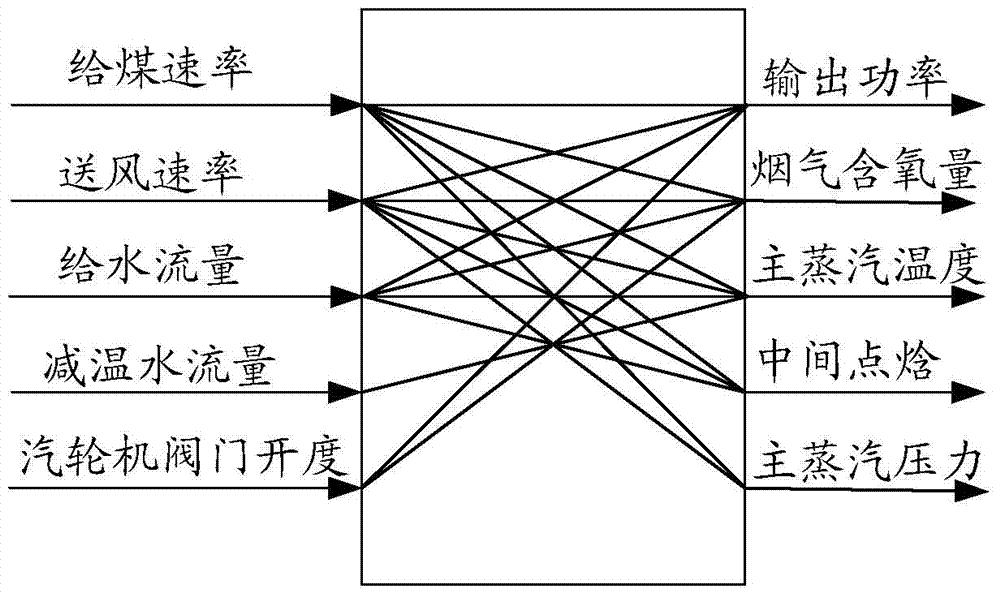

Method used

Image

Examples

Embodiment 1

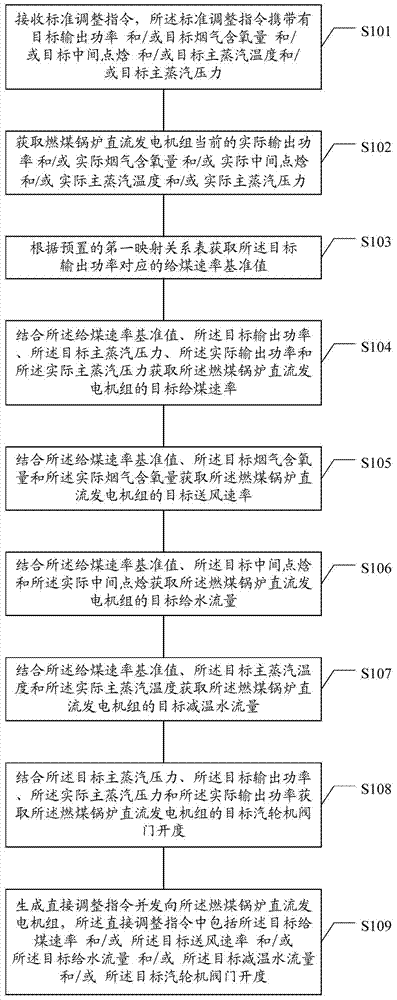

[0037] This embodiment provides a control method for a coal-fired boiler DC generator set, see Figure 1a , the method flow provided by this embodiment is specifically as follows:

[0038] S101. Receive a standard adjustment command, the standard adjustment command carries a target output power and / or a target flue gas oxygen content and / or a target midpoint enthalpy and / or a target main steam temperature and / or a target main steam pressure.

[0039] The output power refers to the power of the coal-fired boiler DC generator set to output electric energy to the grid.

[0040] The oxygen content of the flue gas refers to the oxygen content of the gas in the combustion chamber of the boiler. Combustion requires oxygen, and the pulverized coal injected into the combustion chamber can only be combusted if it is fully mixed with the oxygen in the air. Therefore, the oxygen content of the flue gas is an important indicator of whether the combustion is sufficient.

[0041] The interm...

Embodiment 2

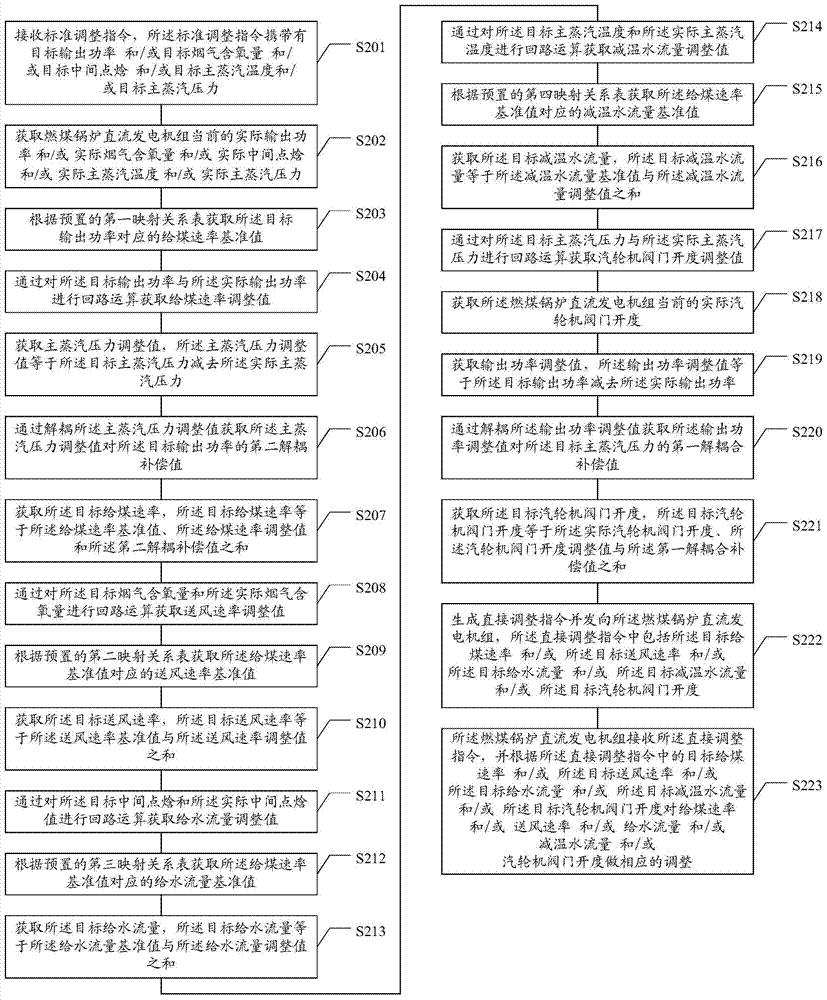

[0088] This embodiment provides a control method for a coal-fired boiler DC generator set, see figure 2 , the method flow provided by this embodiment is specifically as follows:

[0089] S201. Receive a standard adjustment command, the standard adjustment command carries a target output power and / or a target flue gas oxygen content and / or a target midpoint enthalpy and / or a target main steam temperature and / or a target main steam pressure.

[0090] S202. Obtain the current actual output power and / or actual flue gas oxygen content and / or actual mid-point enthalpy and / or actual main steam temperature and / or actual main steam pressure of the DC generator set of the coal-fired boiler.

[0091] S203. Obtain a coal feeding rate reference value corresponding to the target output power according to the preset first mapping relationship table.

[0092] The first mapping table may be determined through on-site experiments. Specifically, field experiments were carried out in the range...

Embodiment 3

[0149] This embodiment provides a control device for a coal-fired boiler generator set, see image 3 , the device consists of:

[0150] The receiving module 301 is configured to receive a standard adjustment command, the standard adjustment command carries a target output power and / or a target flue gas oxygen content and / or a target midpoint enthalpy and / or a target main steam temperature and / or a target main steam pressure;

[0151] The feedback module 302 is used to obtain the current actual output power and / or actual flue gas oxygen content and / or actual mid-point enthalpy and / or actual main steam temperature and / or actual main steam pressure of the coal-fired boiler DC generator set;

[0152] The first feed-forward controller 303 is configured to obtain the coal feeding rate reference value corresponding to the target output power obtained by the receiving module 301 according to the preset first mapping relationship table;

[0153] The first obtaining module 304 is used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com