Boiler drum water level self-adaptation PID (proportion integration differentiation) control method

A control method and boiler drum technology, which is applied in the direction of controlling feed water, steam generation, preheating, etc., can solve the problems of errors, inability to smoothly output the expected control amount, difficulty in setting the drum water level control, etc., and improve the control quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The preferred embodiments will be described in detail below in conjunction with the accompanying drawings. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

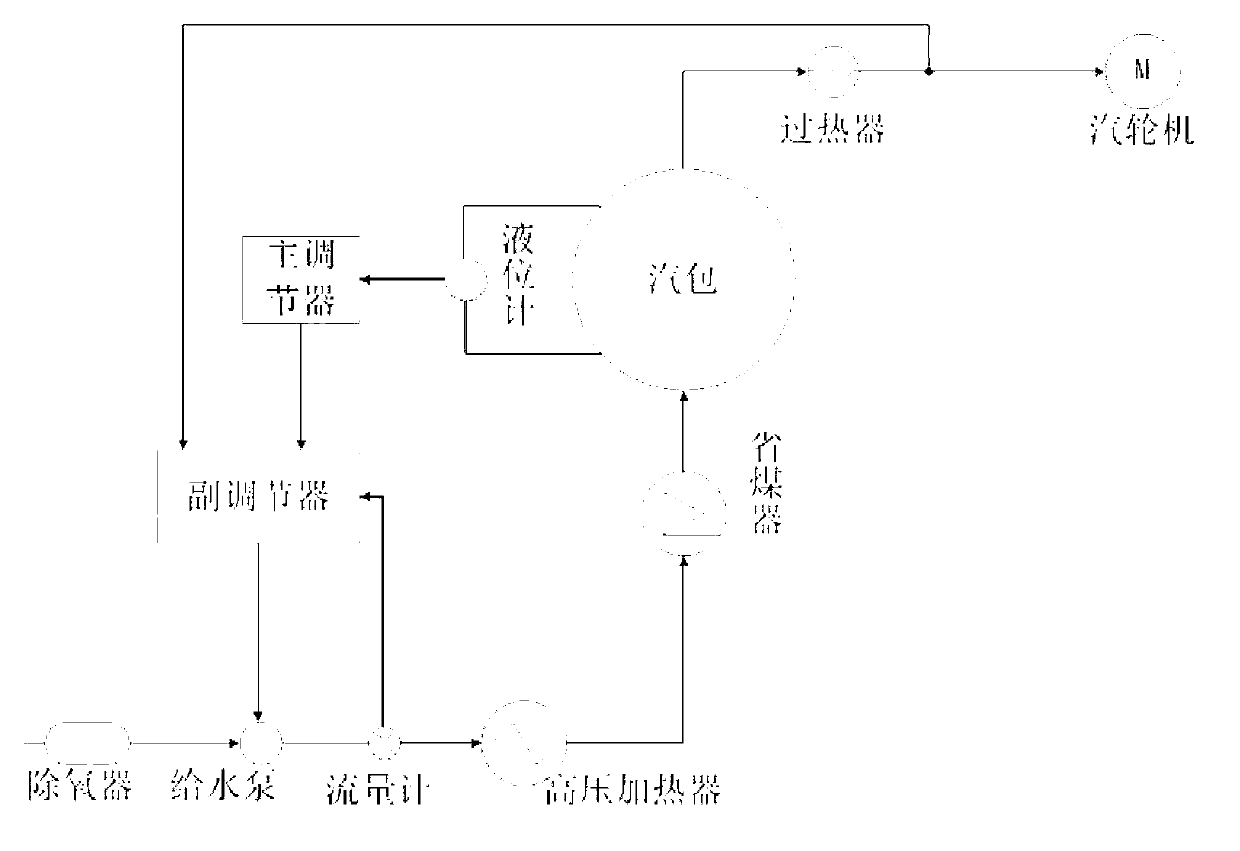

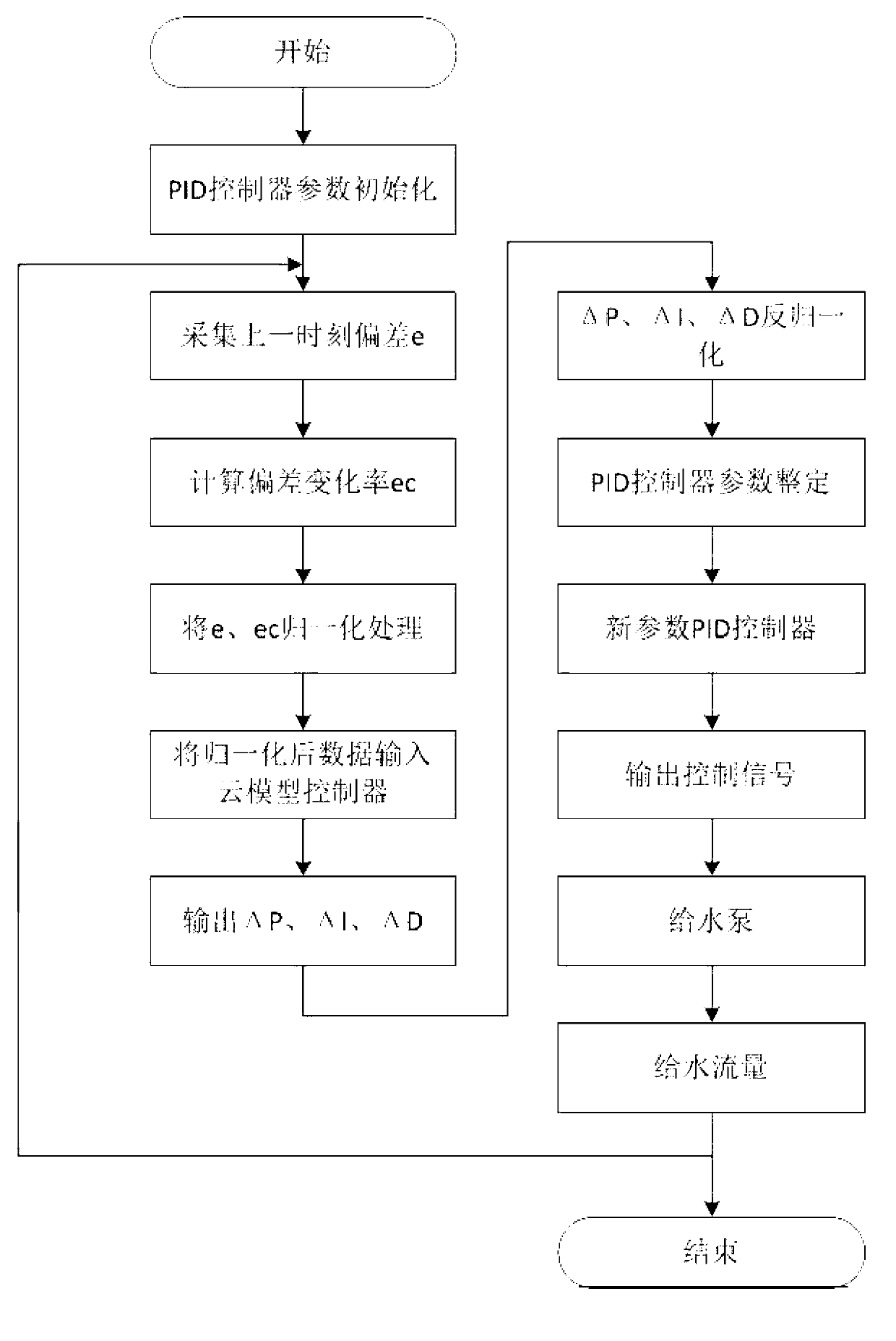

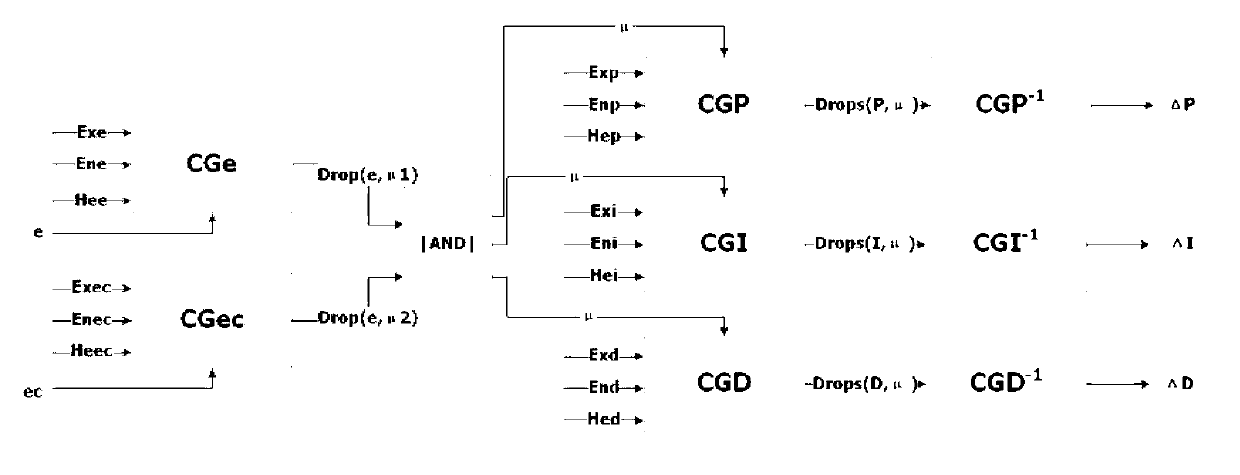

[0040] figure 1 It is a schematic diagram of boiler drum water level adaptive PID control in a boiler drum water level adaptive PID control method provided by the present invention. figure 1 Among them, the three parameter values of the conventional PID controller are adaptively adjusted according to the deviation signal e of the steam flow rate D, the feedwater flow rate W and the steam drum water level H, and the deviation change rate ec. When the control system is disturbed, it can act quickly and realize the steam drum Stable control of water level. The self-adaptive link is realized by a two-dimensional cloud model controller. The deviation signal e obtained by sensor sampling is used to calculate the variatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com