Method for synthesizing zinc ferrite spherical nano material by premixed flame

A nanomaterial, flame synthesis technology, applied in nanotechnology, chemical instruments and methods, iron compounds, etc., can solve the problems of low crystallinity, cumbersome experimental steps, etc., achieve simple preparation steps, good reproducibility, increase The effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

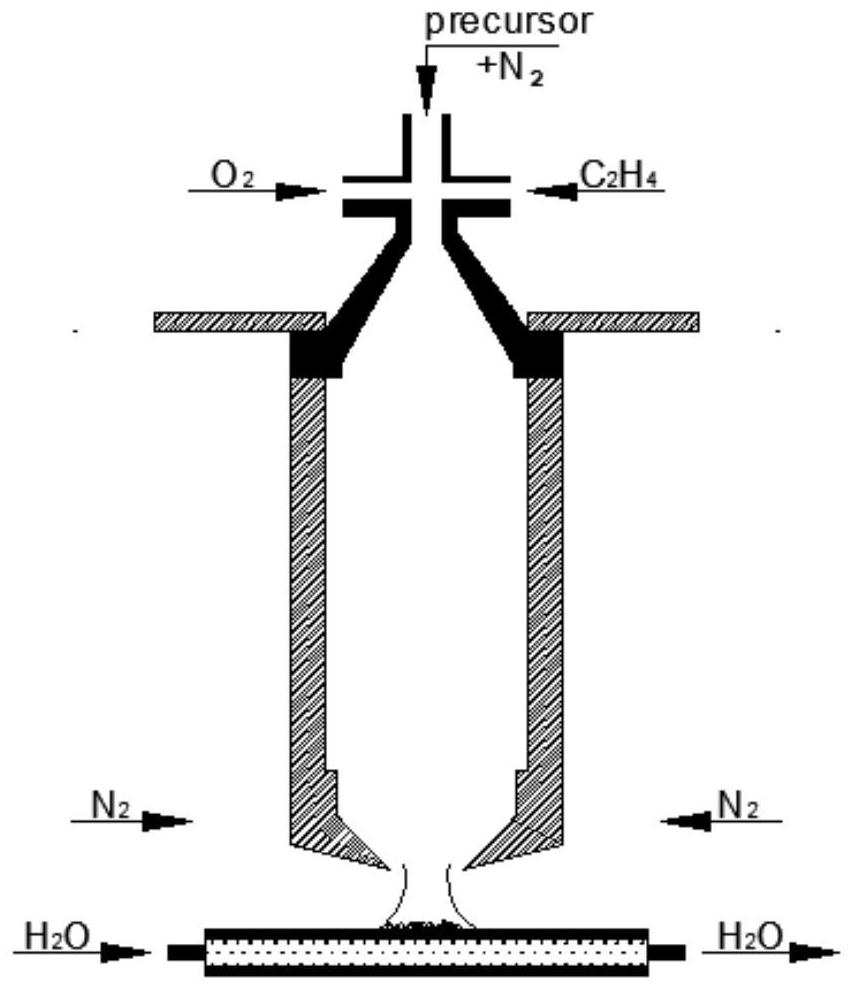

Method used

Image

Examples

Embodiment 1

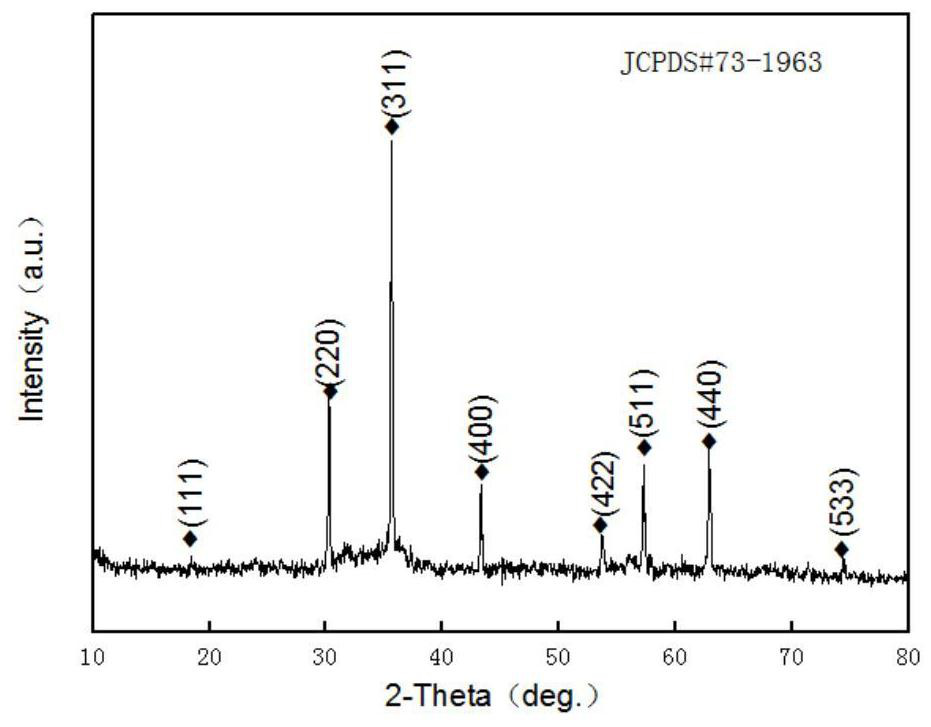

[0032] ZnFe 2 o 4 Preparation of Spherical Nanomaterials

[0033] 2g of Zn(NO 3 ) 2 ·6H 2 O and 8.08g of Fe(NO 3 ) 3 9H 2 O (molar ratio: 0.65:2) was added to 50 mL of deionized water, stirred and mixed evenly, placed in a magnetic stirrer at room temperature and stirred at 250 r / min for 20-30 min, and poured into an atomization device after stirring. Turn on the circulating water cooling system, check whether the water volume of the water pump is sufficient and the liquid inflow in the pipeline, so as to ensure the cooling effect of the water-cooled substrate. Set the burner preheating device and pipeline preheating heating belt at 130°C and 100°C respectively, and set the temperature of the air heating tube at 250°C to preheat the experimental device. After preheating, open the nitrogen valve, check the airtightness of the entire gas circuit, observe whether the value of the Dwyer digital display pressure gauge drops suddenly, increase the flow rate of the protective...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com