High-speed premixed flame furnace for supersonic burning research

A technology of supersonic combustion and flame furnace, applied in combustion chamber, combustion method, combustion equipment, etc., can solve the problems of expensive materials, complex structure, high processing technology requirements, etc., to achieve the effect of precise temperature control and improve control ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

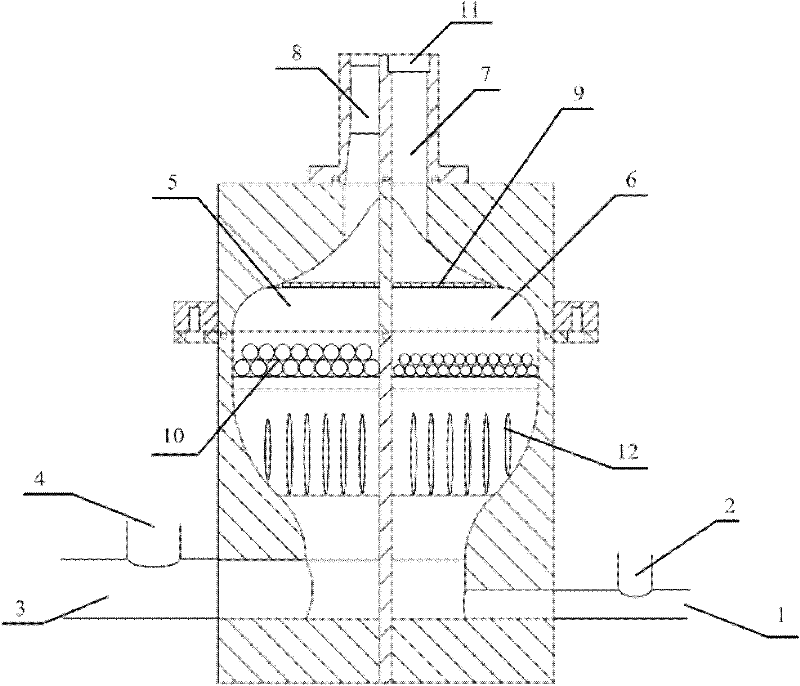

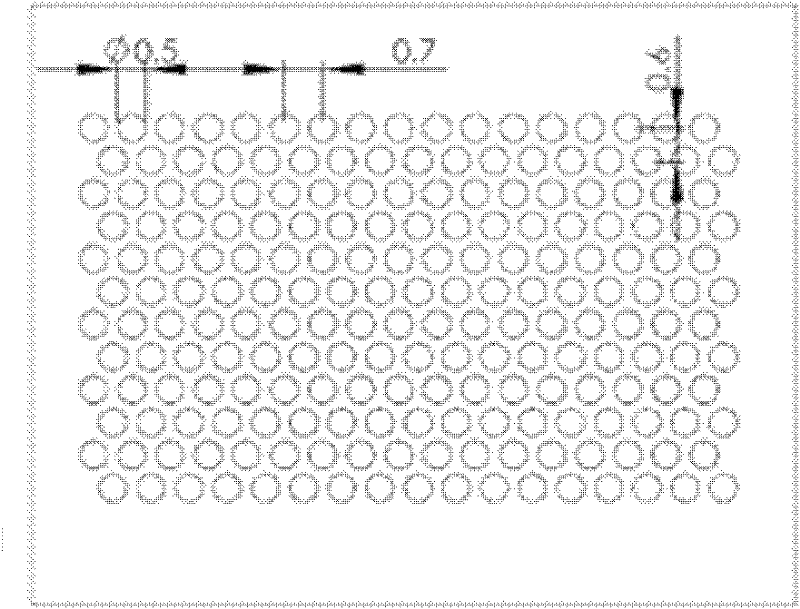

[0038] figure 1 It is a supersonic premixed flame furnace designed by the present invention, including a main flow mixing chamber 5, a supersonic nozzle 8, a wake chamber 6, and a low velocity nozzle 7, wherein the entire supersonic premixed flame furnace is a streamlined structure with small ends and a large middle, Along the longitudinal direction, it is evenly divided into two parts, one part is the supersonic mainstream side, and the other part is the subsonic wake side. Subsonic wake side.

[0039] Wherein on the supersonic main flow side, the entrance of the main flow mixing chamber 5 is connected with a three-way methane pipeline 4 and a three-way air or pure oxygen pipeline 3, and the outlet is connected with a supersonic nozzle 8, and in the main flow mixing chamber 5 from the entrance to the exit in sequence An electrothermal ceramic heater 12, an anti-temper interlayer 10 and a damping net 9 are provided.

[0040] Fuel methane and air or methane and oxygen enter t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com