High-efficiency low-emission combustion chamber head capable of premixing hydrogen

A combustion chamber, low-emission technology, applied in the combustion chamber, continuous combustion chamber, combustion method, etc., can solve the problems of poor uniformity of the outlet temperature field, insufficient hydrogen mixing, combustion mode ablation, etc., to ensure uniformity, improve Combustion stability, the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

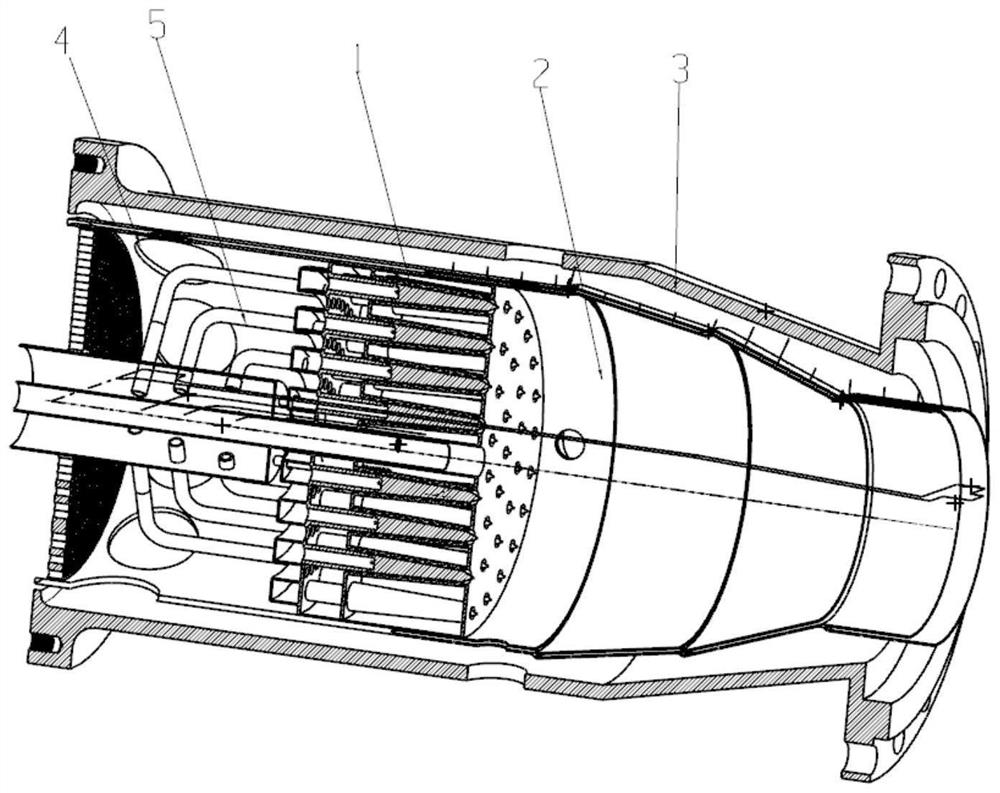

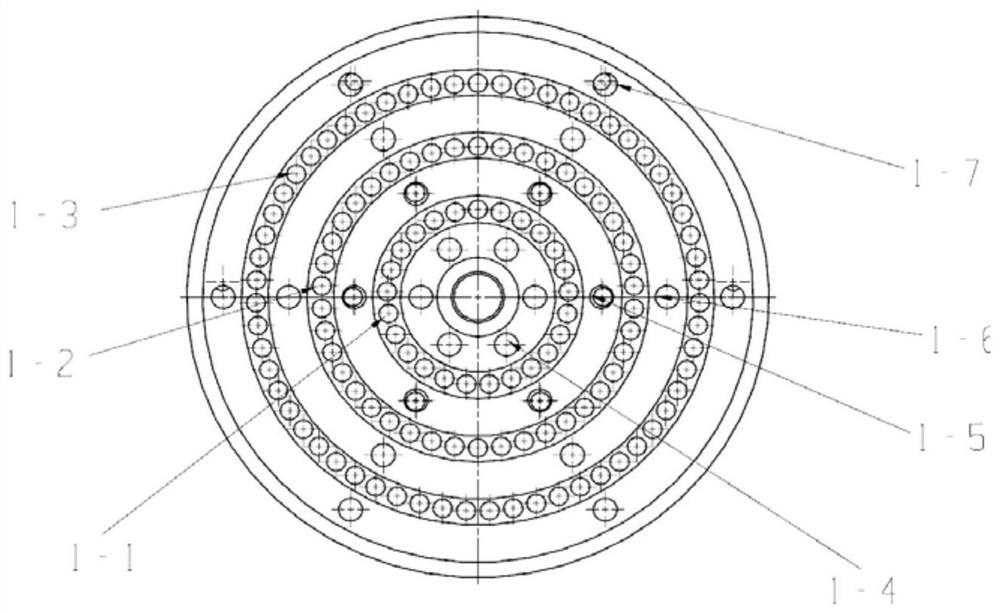

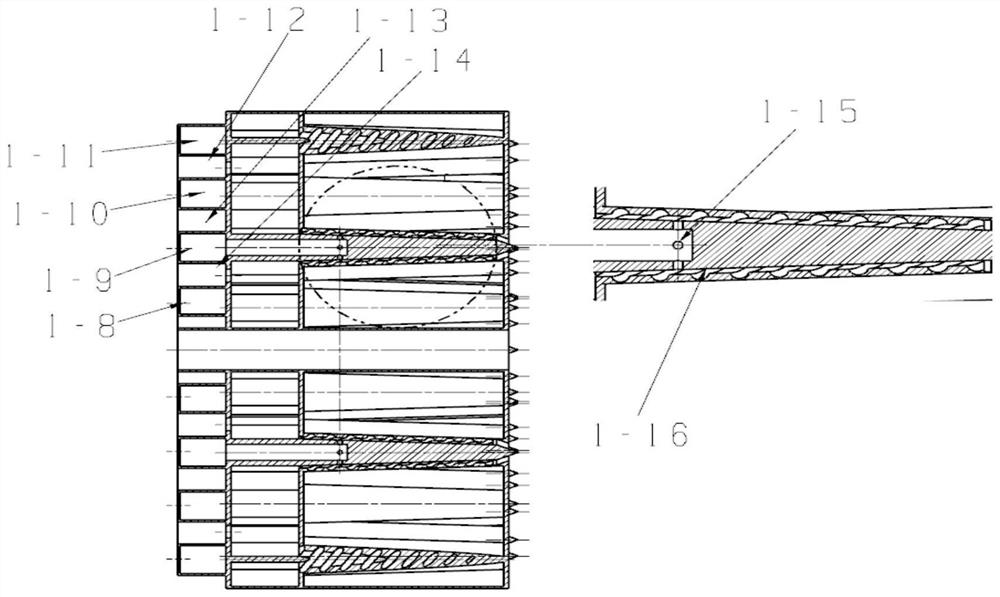

[0022] according to Figure 1 to Figure 7 , The present invention provides a high-efficiency, stable-combustion and low-emission combustor head with hydrogen premixed. The structure mainly includes a hydrogen premixing head 1 , a flame tube 2 , a casing 3 , a perforated plate 4 , and a fuel conduit 5 . Hydrogen is transported from the short central axis 5-6 on the left side of the duct to the multi-stage fuel pipes on the right side of the duct. The first-stage fuel inlet 1-4, the second-stage fuel pipe 5-2 is connected to the second-stage fuel inlet 1-5, the third-stage fuel pipe 5-3 is connected to the first-stage fuel inlet 1-6, and the fourth-stage fuel pipe 5 -4 is connected to the fuel inlets 1-7 of the fourth stage, and then enters the annular cavity corresponding to the inlets of each stage respectively, enters the pre-fuel passage of the premixing section co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com