Micro gas burner

A technology of gas burners and burners, which is applied in the direction of burners, burners, gas fuel burners, etc., and can solve problems such as bending and flame instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

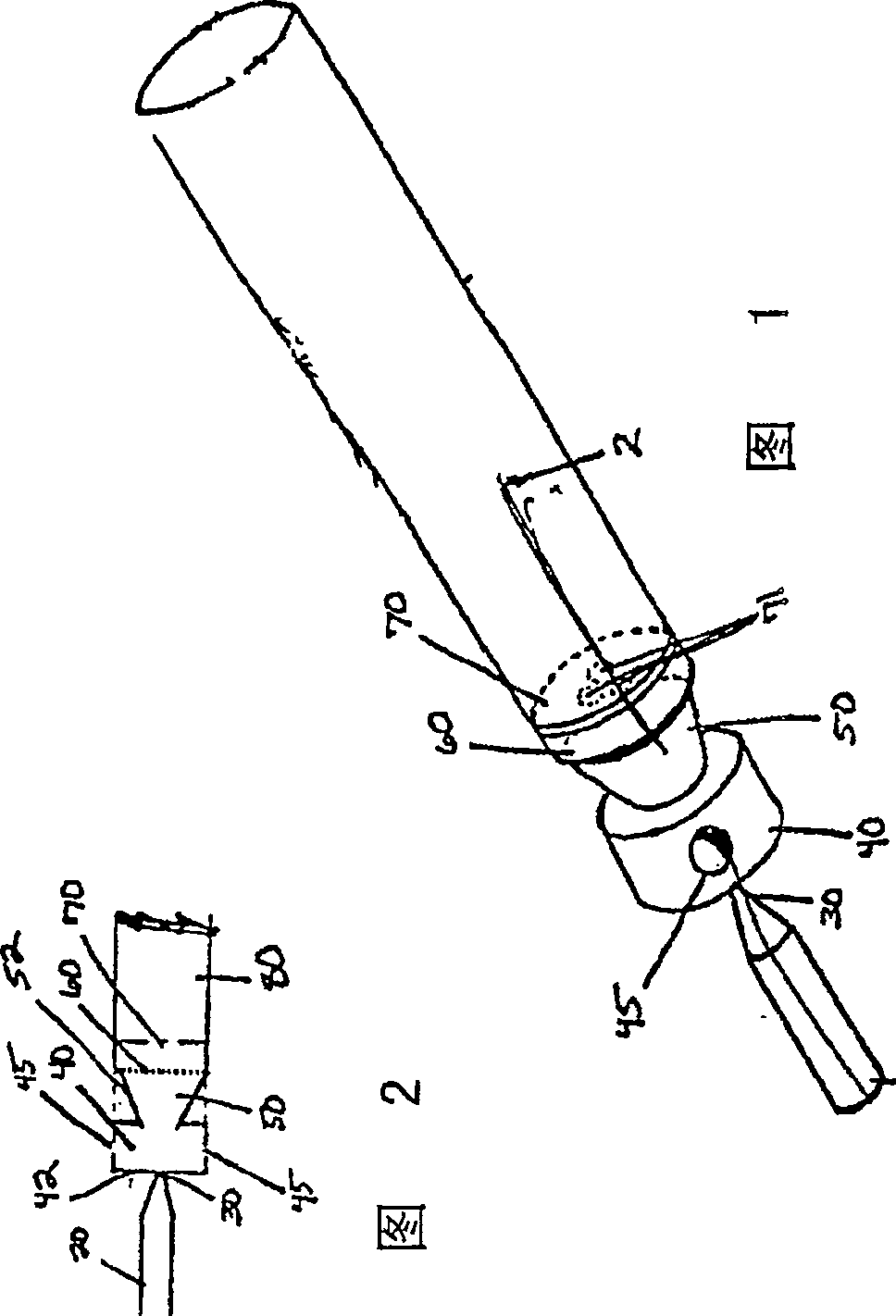

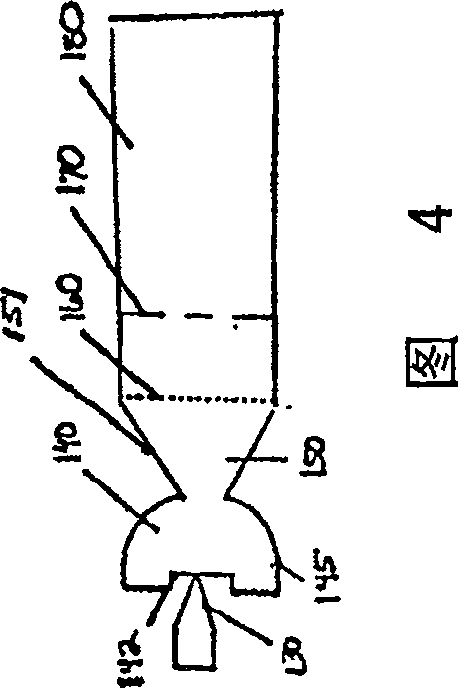

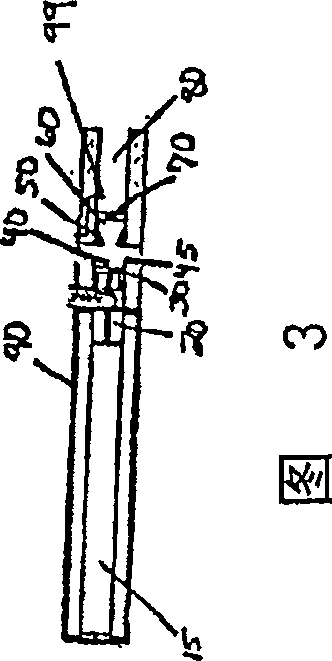

[0043] As shown in the figures, the gas burner 10 comprises a fuel inlet 20, a venturi comprising a nozzle 30 and an oxidation chamber 40 having at least one air inlet 45, a mixing chamber 50, at least one penetrable barrier or mixing screen Mesh 60 and flame holder 70. The gas burner 10 produces a stable premixed flame at a lower fuel mass flow rate than conventional burners. Therefore, lighters employing the gas burner of the present invention are smaller in size than conventional commercial gas lighters.

[0044]Figure 1 shows a gas burner 10 of the present invention. The fuel inlet 20 connects the fuel storage container 15 and the nozzle 30 together, as shown in FIG. 3 . The fuel inlet 20 provides access for gaseous fuel to be supplied to the gas burner 10 therethrough from the storage vessel 15 contained therein. The fuel may be any gaseous fuel known in the art, including low molecular weight hydrocarbons such as methane, ethane, propane, butane, and acetylene. The n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com