Experimental system for measuring propagation speed of laminar premixed flame under high pressure

A technology of flame propagation velocity and experimental system, which is applied in the field of experimental system for measuring laminar premixed flame propagation velocity under high pressure, and can solve the problems of inability to measure the flame propagation velocity and error of liquid fuel or gaseous fuel and oxidant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

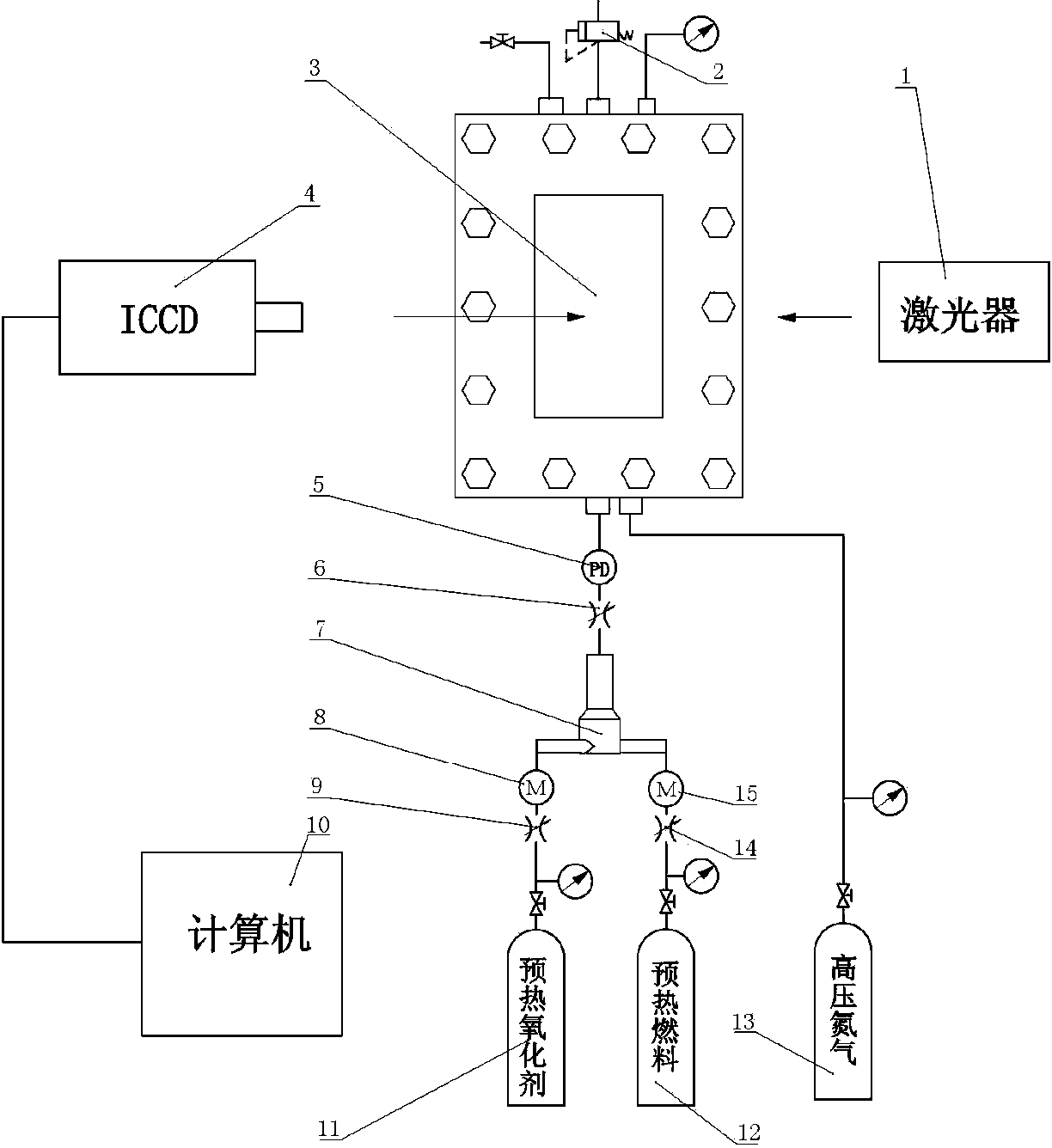

[0016] This embodiment is an experimental system for measuring the propagation speed of laminar premixed flame under high pressure.

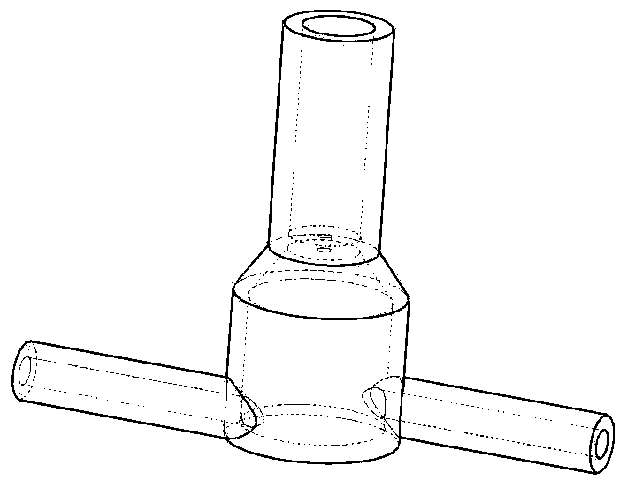

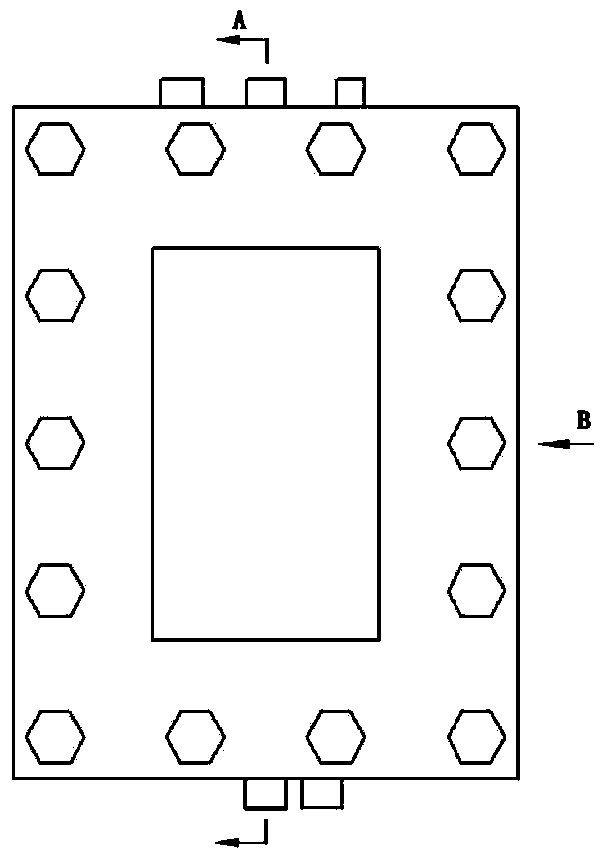

[0017] refer to Figure 1-Figure 6 , the present invention measures laminar premixed flame propagation velocity under high pressure experimental system, including PLIF system, constant pressure valve 2, high pressure chamber 3, volumetric flow meter 5, premixed gas flow regulating valve 6, premixer 7, fuel mass flow rate Meter 8, fuel flow regulating valve 9, preheating oxidant 11, preheating fuel 12, high-pressure nitrogen 13, oxidant flow regulating valve 14, oxidant mass flow meter 15, high-pressure chamber includes front observation window 16, spark plug 17, housing 18, Side observation window 19, nozzle 20, PLIF system consists of laser 1, ICCD camera 4, computer 10, the experimental system is fixed on the test bench, laser 1 and ICCD camera 4 are respectively installed on the front observation window 16 on the high pressure chamber 3 shell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com