Strong-swirling-flow fuel staging ultra-low-nitrogen gas burner

A gas burner and fuel grading technology, applied to gas fuel burners, burners, combustion methods, etc., can solve the problems of reduced oxygen partial pressure, unstable combustion, vibration, etc., and achieve less emissions, simple and reliable structure, and high combustion efficiency full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

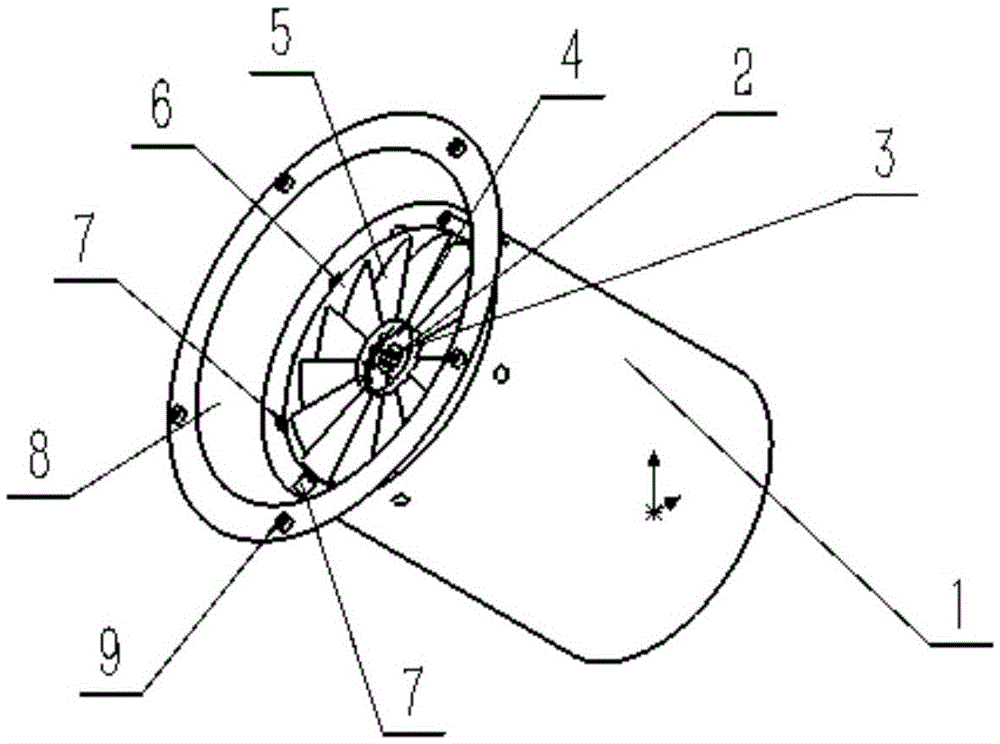

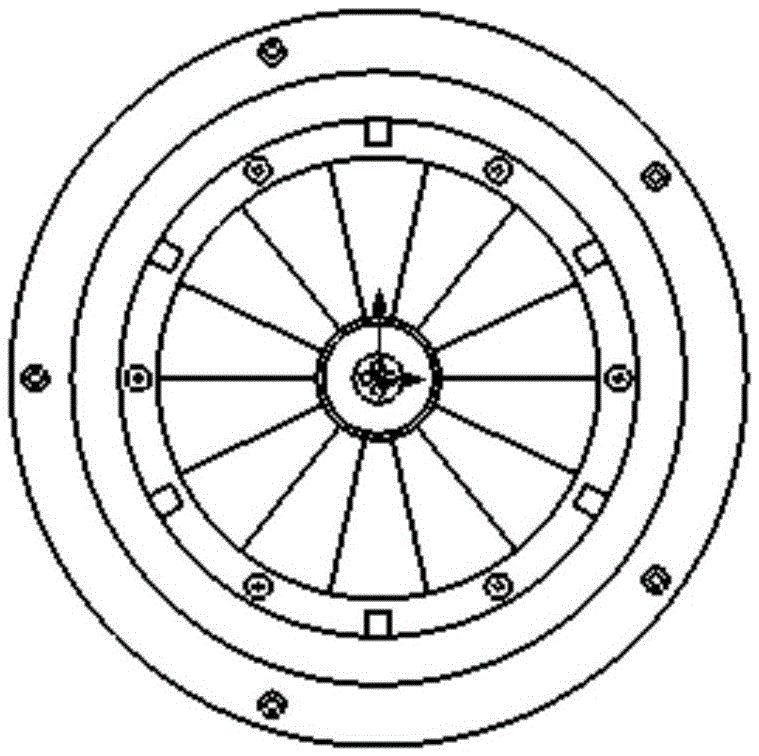

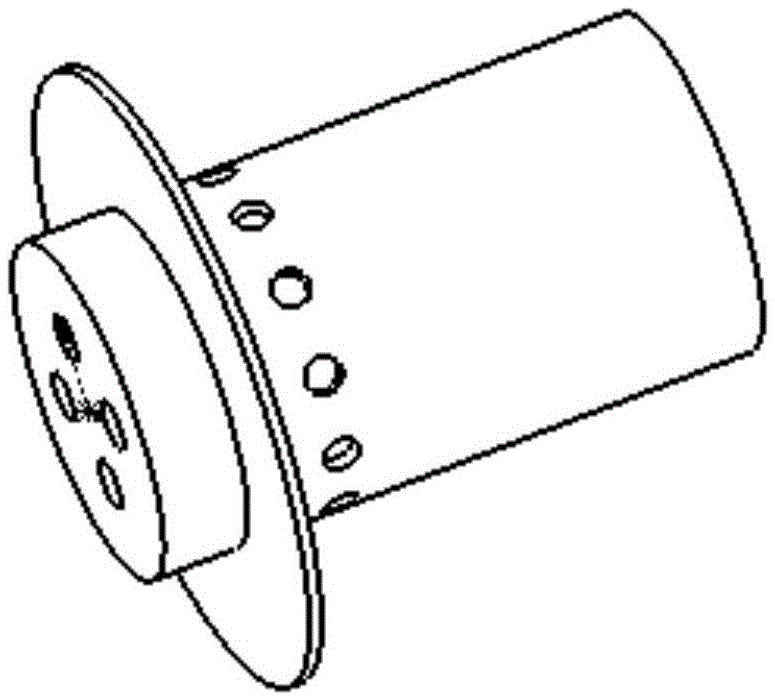

[0024] The following is attached figure 1 , the present invention will be further described through specific embodiments. The attached figure 1 The descriptions of reference signs are as follows: 1. Air channel; 2. Primary fuel nozzle; 3. Primary fuel flame stabilization disc; 4. Swirl disc inner ring; 5. Swirl vane; 6. Swirl disc outer ring; 7. Secondary fuel nozzle; 8, flaring; 9, graded fuel nozzle.

[0025] An embodiment of the present invention discloses a highly swirling fuel staged ultra-low nitrogen gas burner, specifically as attached Figure 1-3 As shown, it includes a combustion head, which includes: a cylindrical air channel 1; a swirl disc arranged inside the cylindrical air channel, the swirl disc includes a swirl disc outer ring 6, a swirl disc Flow plate inner ring 4, the swirl plate 5 arranged between the outer ring 6 and the inner ring 4; a primary fuel nozzle 2 arranged at the center of the burner swirl disk inner ring 4, the primary fuel nozzle includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com