Active heat reclaiming method and device for diesel engine particulate drip catcher

A particulate filter and diesel engine technology, applied in the direction of machines/engines, mufflers, exhaust devices, etc., can solve problems such as unreliable performance, complex systems, and affecting filter elements, etc., to achieve uniform cross-sectional temperature, uniform temperature distribution, The effect of speeding up regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Embodiment 1: The active thermal regeneration method of the diesel particulate filter is: use the exhaust heat of the diesel engine or supplement it with electric heating to make the liquid fuel in the fuel seal tank form a high-temperature saturated vapor with pressure; when the front and rear pressures of the filter element in the exhaust channel When the pressure difference displayed by the sensor reaches the preset value, the central control unit sends a regeneration command to open the fuel outlet valve so that the saturated high-pressure fuel vapor in the fuel seal tank enters the nozzle through the fuel outlet valve, sprays into the main combustion area, and ignites. The nozzle starts to flash and ignites the gaseous fuel vapor; under the action of the double-stage cyclone, the flame is kept in the main combustion area, generating high-temperature gas, flowing through the filter element, igniting the particulate matter deposited on the filter element, until the fro...

Embodiment 2

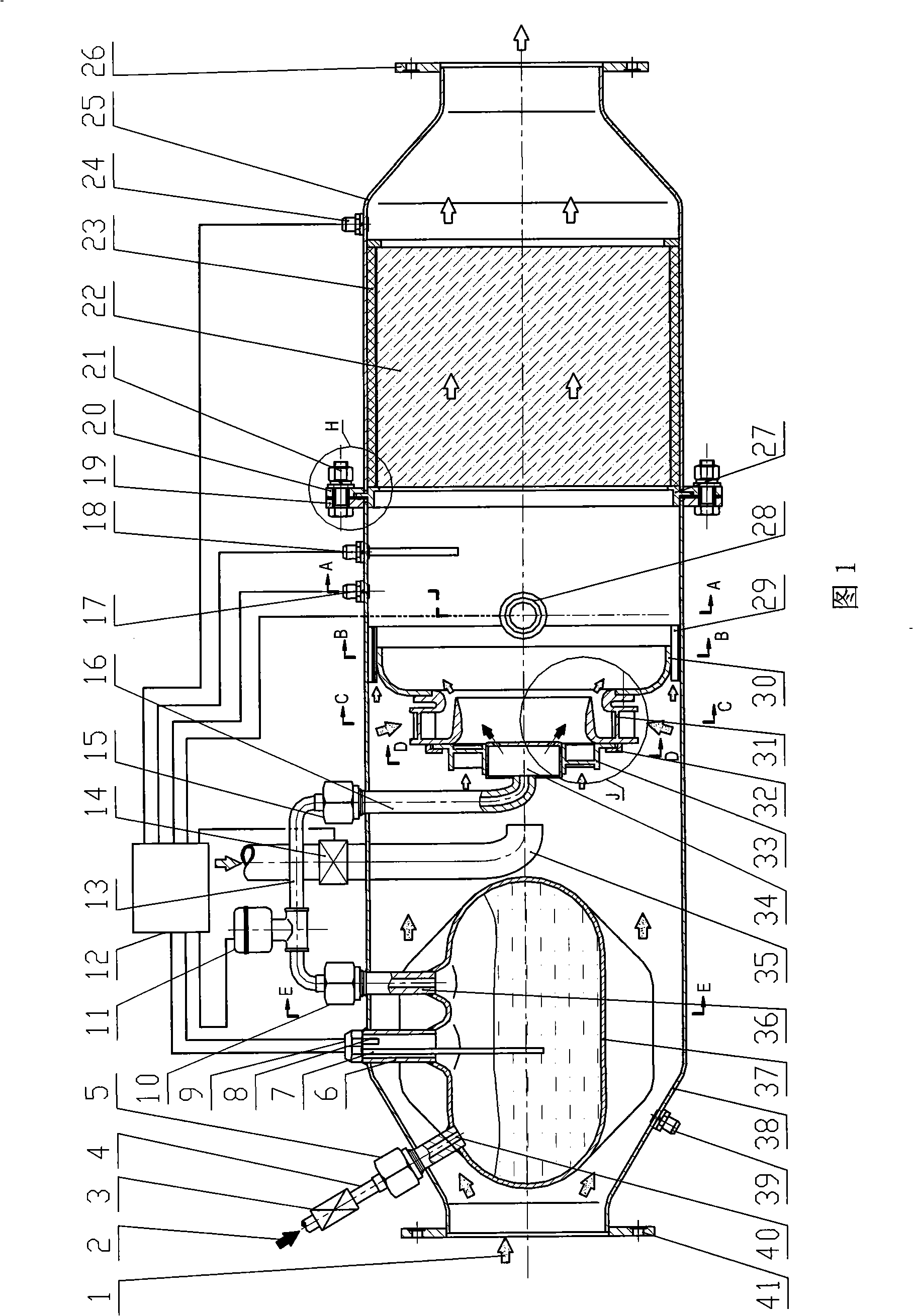

[0068] Embodiment 2: As shown in FIG. 1, the shell of the particle trap is divided into two parts, namely, the shell of the trapping section 25 and the shell of the regeneration section 38. The position is provided with connecting ring 27, and its function is to fix filter core 23 on the one hand, and on the other hand is to two ends housing 25,38 docking positions (as Figure 7 shown).

[0069] A filter element 22 and a filter element vibration-damping insulation layer 23 are installed inside the trapping section housing 25, and a third pressure sensor 24 is arranged downstream of the filter element 23. Lan 26.

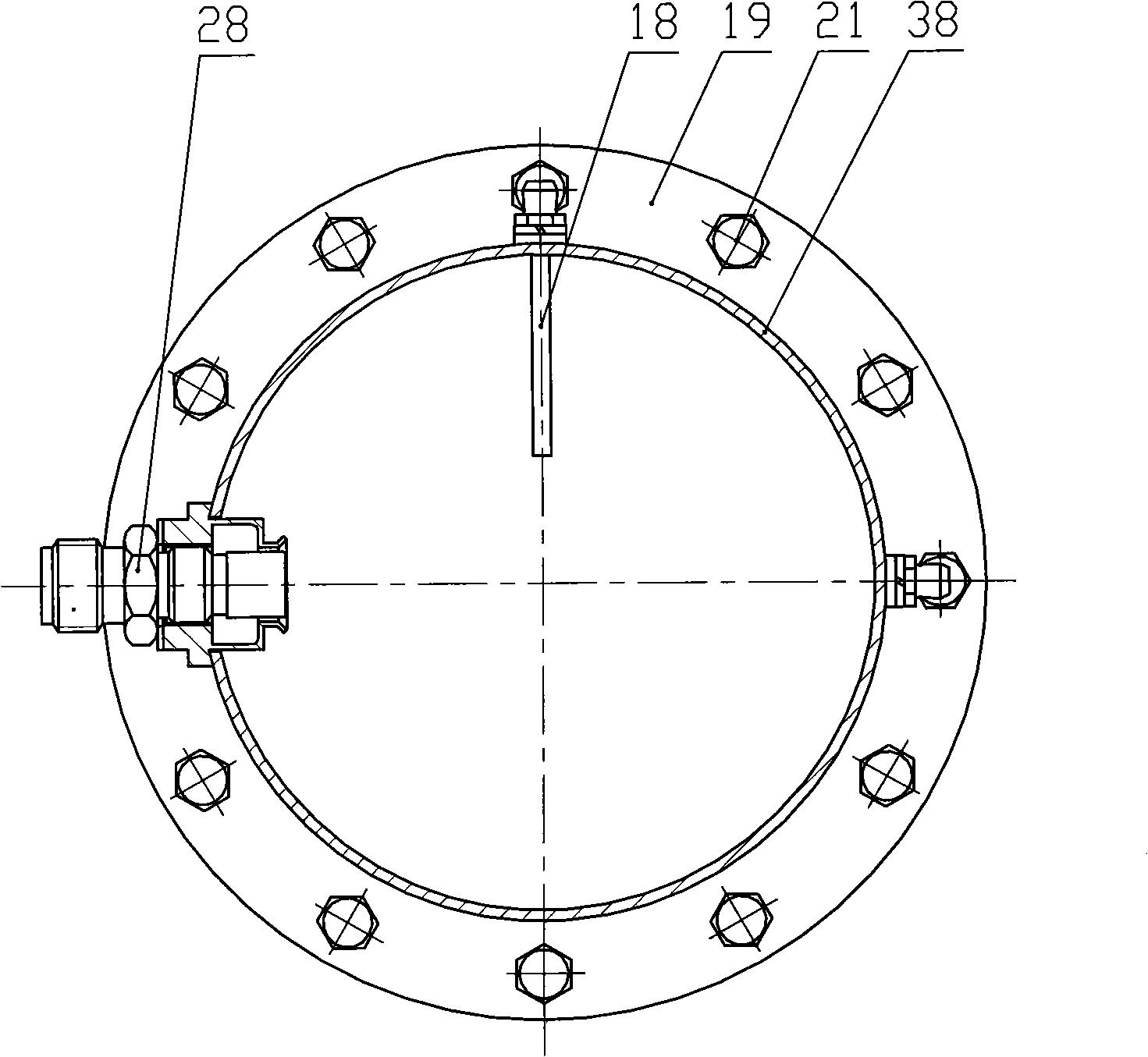

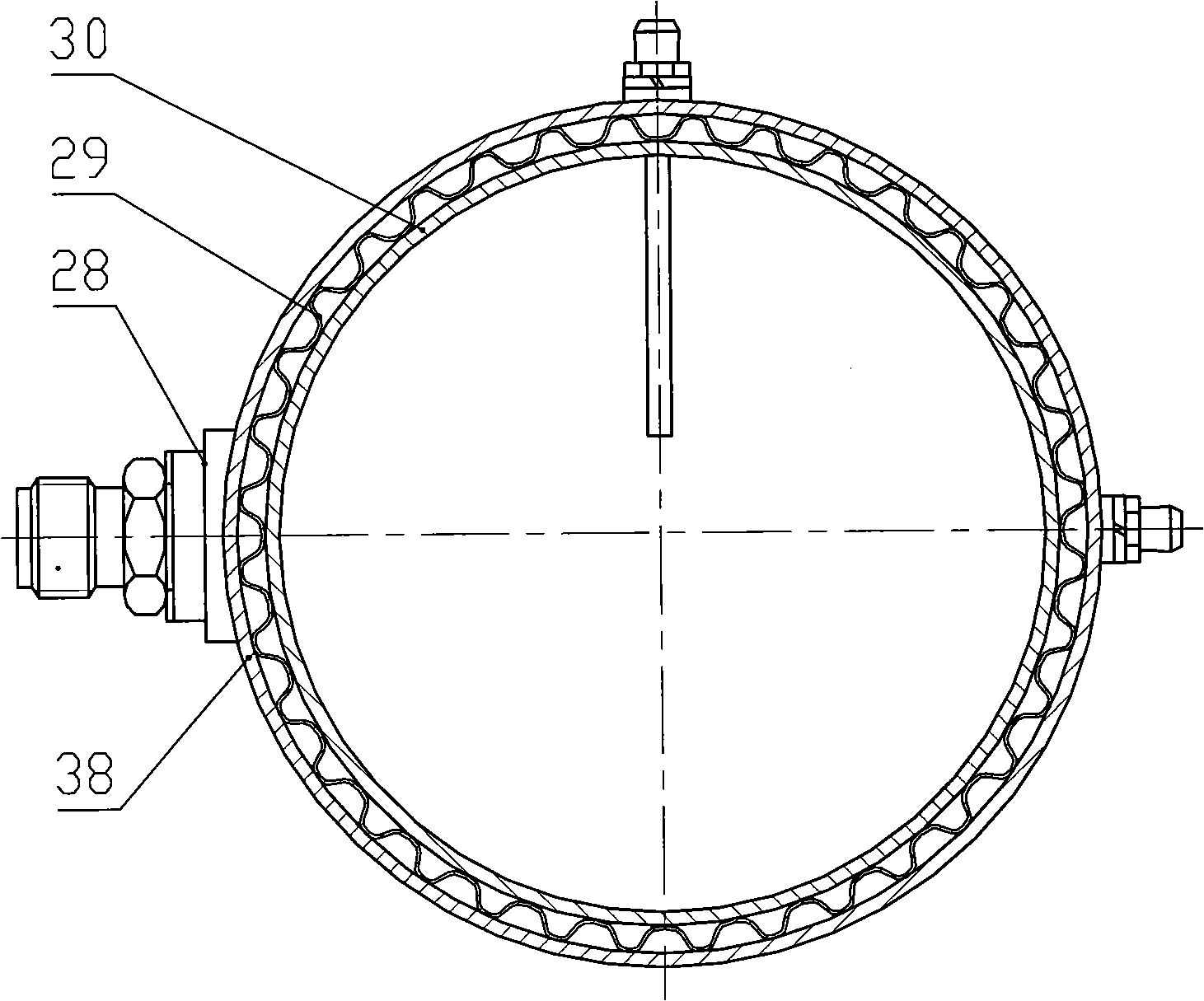

[0070] A flange 41 is provided at the inlet of the casing 38 of the regeneration section, and a fuel tank 37, a secondary air input pipe 35, a fuel nozzle 34, a primary cyclone 33, a secondary cyclone 31, and a head ring 30 are installed inside. and other components. An oxygen content sensor 39 , an ignition nozzle 28 , a second pressure sensor 17 and a temperatur...

Embodiment 3

[0077] Embodiment 3: the difference between this program and embodiment 2 is that 1. the fuel used is different, and what is stored in the fuel tank 37 is the fuel with a boiling point higher than the engine exhaust temperature, such as diesel oil; 2. in the fuel tank 37, an additional An electric heating facility is provided, that is, an electric heating wire 53 is provided in the fuel tank 37, see for details Figure 18 .

[0078] A heating wire 53 and its installation rod 51 are arranged in the fuel tank 37 , and the installation rod 51 is fixed on the lead-out seat 9 . Because the exhaust gas 1 of the diesel engine does not necessarily make the diesel oil boil to generate high-pressure steam, after the regeneration program starts, the central control unit 12 energizes the heating wire 53 to heat the fuel until the pressure sensor 50 shows that the pressure in the fuel tank 37 reaches the preset value , at this time, the fuel tank 37 has high temperature and high pressure s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com