Experimental method and device for measuring heat release rate pulsation by adopting multiple microphones

A technology of heat release rate and experimental device, applied in the direction of thermal development of materials, etc., can solve the problems of expensive device, complex measurement optical path, lack of spatial resolution, etc., and achieve the effect of low cost, simple structure, convenient operation and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

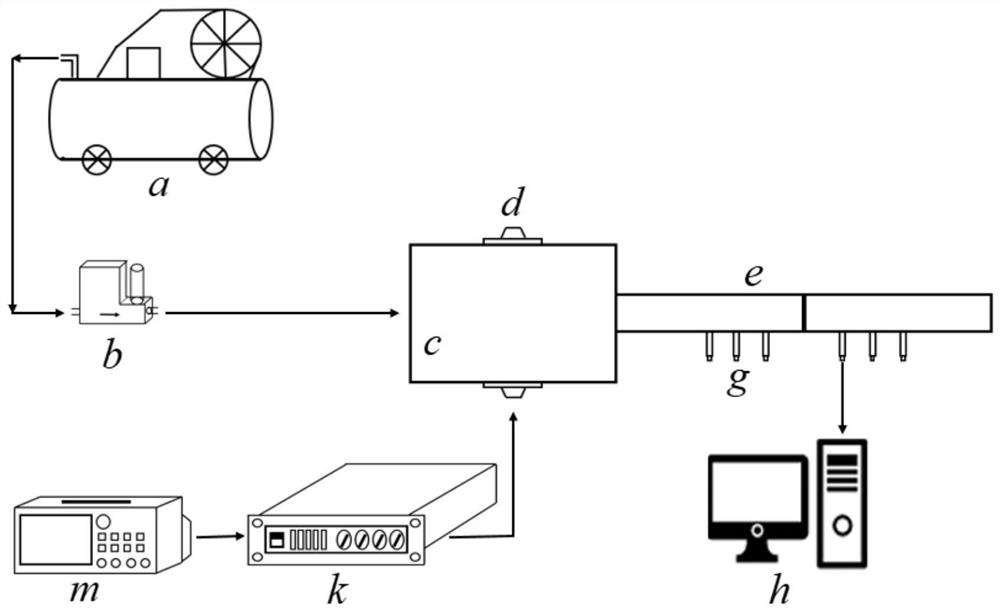

[0037] The present invention will be described in detail below in conjunction with the accompanying drawings. In this embodiment, an experimental platform for measuring the pulsation of the combustion heat release rate by the multi-microphone method is set up, such as figure 1 As shown, by changing the average flow velocity of the gas and the frequency of the acoustic disturbance signal, the pressure fluctuation and combustion heat release rate pulsation in the open tube under different working conditions are measured. The specific implementation is described as follows:

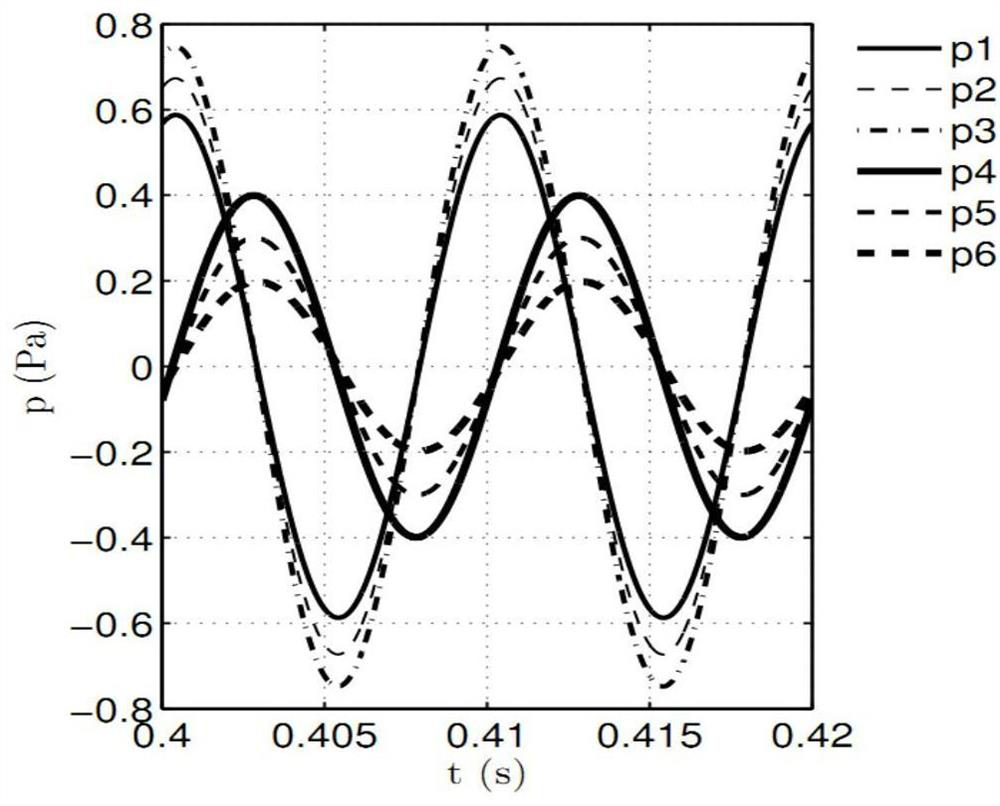

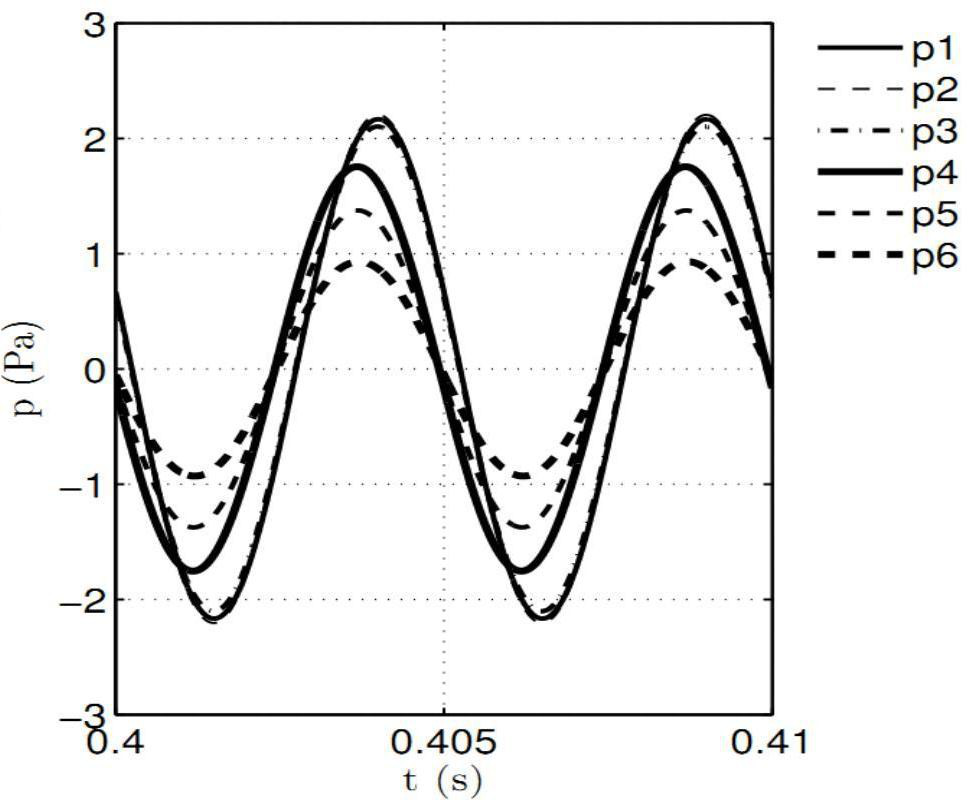

[0038] In this embodiment, the heat source in the open tube is a nickel-chromium alloy resistance wire, and a DC power supply is used to heat the resistance wire to simulate a combustion field. By adjusting the voltage and current of the DC power supply, the power of the heat source can be adjusted. The nickel-chromium alloy resistance wire has a diameter of 0.4 mm, and is wound into a coil with a coil diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com